MMS Blog

Speedy Setups Secure a Quick-Turn Niche

A talent for live-tool lathe changeovers keeps Kustom Machining & Manufacturing’s customers coming back for more.

Read MoreZero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.

Read MoreFriction Stir Welding & Machining On One Platform

USA CNC Manufacturer C.R. Onsrud showcases friction stir welding and machining on one machine to reduce part handling, fixturing, and eliminate the need for additional machinery and employees. (Sponsored)

Read MoreAutomated Multitasking Machine Drops Parts Complete

This automated multitasking machine with an integrated robot eliminates the need to run parts across multiple machines, saving floor space, setup time and labor.

Read MoreCan Transparency Bring More Efficient Sourcing?

A resource that aims to be free for machine shops asks detailed capability information so parts can be matched to producers, and OEMs can target RFQs to shops that are ready to run the work.

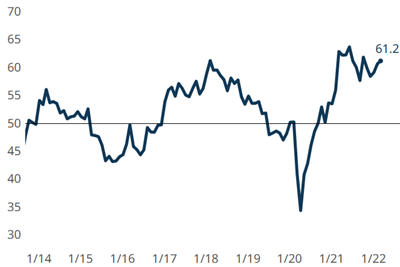

Read MoreMarch Metalworking Activity Continues January Trends

The Gardner Business Index: Metalworking saw expanding activity in new orders, production and backlog at slightly increased rates in March.

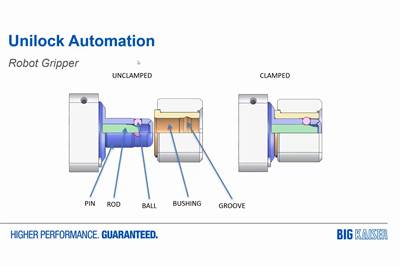

Read MorePutting Production on Repeat with Machine Tool Automation

Cobots and automation advances have spurred tooling and workholding innovations like Big Daishowa’s zero-point workholding system and EWA fine boring head.

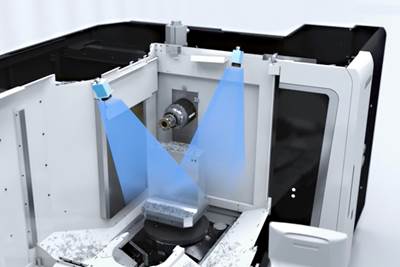

Read MoreAI Chip Flushing Keeps the Lights Out

Swiveling, camera-guided coolant nozzles solve a CNC machining automation problem that is ideal for artificial intelligence (AI).

Read MoreAdditive Manufacturing to the Rescue — Again

AM is the perfect candidate to solve production problems that began during the pandemic.

Read MoreBack to School: CNC School Co-Locates With Machine Shop

By allowing this CNC school to operate inside its facility, this machine shop benefits as much as the school does.

Read MoreUsing (And Scaling) FDM 3D Printing for Production

Maxwell June’s razor press, which is designed to combine the ease of use of a disposable razor with the environmental and cost benefits of a wet shaving system, is made via FDM 3D printing. How did the company make this choice, and how does it plan to scale up?

Read MoreThe Role Of Standard Work In Industry 4.0

Are you looking to transform your machine shop into a well-oiled, digitally connected workplace? If so you've likely identified the importance of aligning people, processes, and systems for a successful digital transformation.

Read More