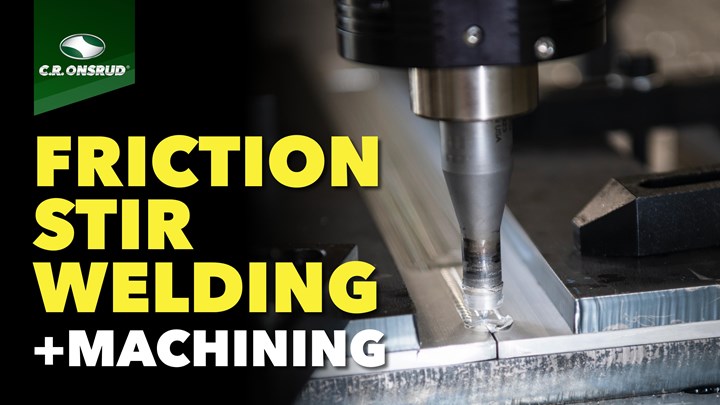

Friction Stir Welding & Machining On One Platform

USA CNC Manufacturer C.R. Onsrud showcases friction stir welding and machining on one machine to reduce part handling, fixturing, and eliminate the need for additional machinery and employees. (Sponsored)

Share

What Is Friction Stir Welding?

With the use of minimal heat (caused by friction) and high pressure, the friction stir welding technique blends (stirs) softened particles together at the seam to fuse (weld) different parts into one molecularly cohesive piece. This unique welding process can produce defect-free bonds without the use of flux, fillers, or a shielding agent. Friction stir welding is typically a standalone process, requiring a specialized CNC machine. Most manufacturer’s use another machine when it comes to removing burrs or “slag” or when milling the part for additional form, fit, or function. C.R. Onsrud, however, performs friction stir welding and CNC milling operations on a single machine for a 2-in-1 solution.

Why/When is Friction Stir Welding used?

Friction Stir Welding is a preferred method in industries such as aerospace, automotive, and shipbuilding for offering a seamlessly strong bond between materials that otherwise would be difficult to weld (e.g., aluminum, dissimilar materials, steel, alloys). It also provides value to “lightweighting” industries by bonding materials without the additional weight caused by bolts and rivets, for example.

While other methods of welding are slow, friction stir welding brings with it the advantage of a clean, safe, automated process for consistent, repeatable results. Not only does it deliver higher joint strength than many other methods, but the fused area in most cases is stronger than the individual base materials.

What are the advantages of this 2-in-1 Machining Solution?

Combining friction stir welding and milling on the same machine reduces material handling, changeover time, and fixturing. Traditionally, additional steps are needed to complete a friction stir welded part for production. Manual work, or in many cases, other machinery is needed to perform such tasks as removing a leftover burr, tapping threaded holes, milling slots, and/or sawing off end pieces. While manual work is slow and inconsistent, a second machine costs money, takes up floor space, and often requires an additional program and an employee to run it. This is where a 2-in-1 machine can reduce the costs of a “multi-process” friction stir welded component. You can friction stir weld and perform all your operations (e.g., drilling, milling,

tapping, and/or sawing) without ever moving your part, buying additional equipment, or needing to hire employees to perform secondary processes.

This 2-and-1 solution is available on a variety of 3- and 5-axis C.R. Onsrud machines, ranging in work envelopes from 4′x8′ to 20′x100′. Let C.R. Onsrud outfit your shop floor with a 2-in-1 machining center, and watch how quickly you’re seeing a positive return on your investment.

Interested in learning more?

Contact C.R. Onsrud today!

Call: 1-704-508-7000

Email: sales@cronsrud.com

Request Brochure

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.