MMS Blog

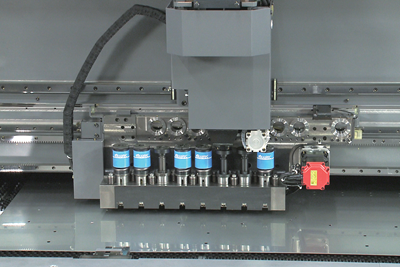

Fabrication Machine Automates Production of Flat Parts

While generalized automation systems are certainly useful, sometimes narrowly focused automation is exactly what a shop needs.

Read MoreVideo: Shifting into Shop Ownership

Mike Budde, owner of Budde Precision Machining, shares his experience with buying a machine shop and what he’s learned in his two years of shop ownership.

WatchHow To Passivate Stainless Steel Parts

You've made sure the parts were machined to spec. Now, make sure you've taken steps to protect those parts in the condition your customer expects them.

Read MoreFocus on Throughput Empowers People and Machines

Lessons learned in robot-tending coordinate measuring machines (CMMs) translate well to a self-correcting multi-tasking machining process.

Read MoreHow to Scale a Job Shop for Growth with Fewer People

Front office disorganization and poor shop floor communications don’t just reduce a job shop’s efficiency; they are a barrier to growth. Having the right kind of ERP system can be the key to improving profitability and scaling for future growth

Read MoreDigital Tools Meet Practical Applications

Digital manufacturing will see a much larger footprint at IMTS 2022 thanks to technologies that bridge the gap between the digital and physical.

Watch6 Ways Additive Manufacturing Will Change in the Next Decade

Where will additive manufacturing go in the next 10 years? Stephanie Hendrixson and Pete Zelinski offer six ideas in the latest episode of the AM Radio podcast.

Read MoreReflecting on Women's Role in Manufacturing

Editors across sister publications of Modern Machine Shop share their thoughts and experiences being a woman in manufacturing.

Read MoreThe Right (Machine) Tool for the Right Job

This high-production shop uses both mechanical and CNC Swiss machines to make parts, but which machine is right for which job?

WatchTurn-Mills 101

Turn-mills are a type of multitasking machine that can shorten cycle times and help facilitate lights-out machining for two common machining types.

Read MoreImprove CNC Programs With User-Defined G, M Codes

CNC operators can program user-defined G and M codes to call custom macros and improve upon or replace existing codes, which can in turn improve production.

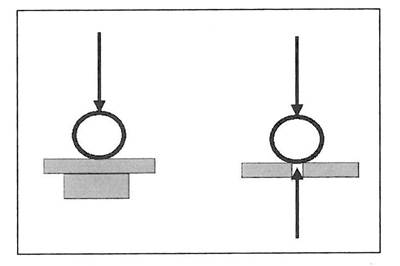

Read MoreDifferential Gaging: 2 Big Benefits for In-Process Part Control

Differential gaging offers benefits like reducing operator influence and enabling quick in-process checks.

Read More