-

SPONSORED

-

-

-

-

-

MMS Blog

Scanning For Process Improvements

A coordinate measuring machine with a constant-contact scanning probe makes it possible to get better, more complete information about workpiece features, especially contours. Two shops talk about how this information helps streamline their production processes.

Read MoreLow-Cost Machines Meet High-End Controls

Mold and die makers have been less than enthusiastic about low-cost VMCs in a large part because their controls typically aren't designed to deliver the high performance 3D contouring capabilities so necessary to cutting cores and cavities. But two companies are out to change all that by bringing together low-cost machining capabilities and high-end contouring control on a single platform.

Read MoreFind The Time

This mold shop shows where to look. Faced with tighter lead times, it achieved faster workflow by using existing machinery and manpower in more efficient ways.

Read MoreWinning A Place For The First CMM

Automated inspection plays a key role in this historically non-CNC shop, thanks in large part to the shop's system for efficient CMM setup.

Read MoreHow Accurate Is Your Machining Center?

Virtually every machine tool builder lists, as part of a machine's specification, accuracy and repeatability figures. What's generally not given is the method used to arrive at the figures. Though these methods are defined in linear positioning standards, not all builders use the same standards.

Read MoreDispelling Small Machine Shop Myths

Many job shops start in a garage with a used mill and a manual lathe. The owners of this Utah job shop took a different tack. Along the way to a very successful business, they've debunked a bunch of myths commonly held about job shops.

Read MoreTying It All Together

This combination product line manufacturer and job shop is a classic example of an environment that calls for a fully integrated CAD/CAM system.

Read MoreThe Flow Through CAM

The route from CAD to CAM to CNC can meet blockage both upstream and downstream from the programmer. However, this shop cleared away most of the obstacles to efficient electronic transfer just by updating its CAM system. The results include a new level of efficiency and new capabilities for a 10-year-old machine.

Read MoreWhy Not Change What You're Doing?

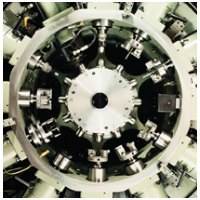

This Canadian screw machine shop built early success with automatic and mechanical multispindles. Introduction of rotary transfer technology has accelerated growth and helped solve other production problems. Here's why they made the move and how it has impacted their shop.

Read MoreInstalling That First EDM

This shop did it right. Their experiences provide useful guidelines for successfully installing a wire machine in a shop new to EDM.

Read MoreEDM Market Dictates New Machine's Features

Japanese EDM builder Sodick is introducing a new wire EDM model to the U.S. market at this year's Westec show in March, 1998.

Read MoreAnti-Electrolysis Is Pro EDM

A new breed of power generators for wire EDMs has options for reducing, even eliminating, one of the unwanted side effects of this very versatile metalcutting process.

Read More