Why Not Change What You're Doing?

This Canadian screw machine shop built early success with automatic and mechanical multispindles. Introduction of rotary transfer technology has accelerated growth and helped solve other production problems. Here's why they made the move and how it has impacted their shop.

Share

Like many screw machine shops, Magnum 2000 of Mississauga, Ontario, Canada started with one person and a single Brown & Sharpe screw machine. They recently moved into a new 40,000-square-foot facility. Their current plans include opening a new plant outside El Paso, Texas within the year to make parts for automotive companies and their suppliers located along the Maquiladora corridor between Mexico and the United States.

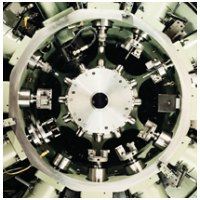

Magnum is about high volumes. They operate with lot quantities that start at 100,000 and go up to 6 million. They have evolved their business from that single "Brownie" to 46 screw machines including 22 Davenports, four Euroturn six-spindles, eight Hydromat rotary transfer machines and five CNC lathes.

Magnum's increasingly sophisticated machines have mirrored the demands of their customer base, primarily automotive OEMs and tier-one suppliers. Moving from stand-alone mechanical screw machines to stand-alone CNCs and now to rotary transfer technology has helped Magnum grow and has fueled steadily increasing customer demand for parts made in this shop.

We talked to company president Joe Skupnik and general manager Christine Seidl about how and why they made the technology decisions that have spurred the growth of their business. Their reasoning has relevance for shops at any level of the volume production continuum.

Best Of Times/Worst Of Times

At one time, Magnum was running 23 automatic screw machines. These were traditional, cam-actuated mechanicals that once set up, made good parts fast. Problem was getting them set up, keeping them running, and then efficiently moving on to the next job.

"When you looked at total time for a job, including setup, run time, second operations and tear down," says Mr. Skupnik, "we were getting about 50 percent efficiency with those machines."

During the last deep recession, inefficiencies in the process became critical to survival. As work dried up, competition for any of the few jobs being let became vicious, to a point where fractions of a cent per piece determined who got work and who did not.

That sent Mr. Skupnik in search of a competitive advantage. "Many shops like mine were trying to remain competitive by shaving fractions off their cycle times," says Mr. Skupnik. "However, that approach addresses only a fraction of the problem. At the core is total process efficiency. Improving efficiency was the only way to survive in that climate so I began looking for new equipment that would help us compete."

Process Analysis

A close evaluation of Magnum's overall manufacturing process showed some areas where improvement could be made. The fundamental question was how to improve overall efficiency of the working machines. For example, if a cycle is timed to produce 1,000 parts per hour, at 100 percent efficiency there should be 8,000 parts at the end of a shift. "Obviously, 100 percent is a target goal that is not achievable," says Ms. Seidl. "Operators need to take breaks, tools need to be replaced, bar stock runs out, and so on. There are many factors that influence the efficiency of a run. But some of them are inherent in the technology itself. Too often we were getting about 50 percent efficiency with our machines for all these reasons. Bottom line was that at the end of 8 hours there were 4,000 parts and not 8,000. That's why we looked into technology that could get these efficiency numbers up."

Inherent in mechanical screw machines is the need for close monitoring. "Per piece cycle time is not the issue for mechanicals," says Mr. Skupnik. "For us, cycle times are comparable between mechanicals, multispindles or rotary transfer. What moved me away from relying primarily on mechanicals for the majority of our production requirements was the amount of operator monitoring and intervention they required."

It's not a matter of manpower so much as the allocation of manpower. "Efficiency gains are made when your operator doesn't need to wait for the moment the bar runs out to catch the end of the bar. Or, the need to have an operator standing by to pick out parts that may fall into the chip bin," says Ms. Seidl. "These very close monitoring requirements are unnecessary with our newest multispindles and rotary transfer machines primarily because these machines are designed to operate more autonomously than our mechanicals."

Reducing Secondary Operations

Additional processing efficiency gains can be made by reducing or eliminating secondary operations. In most screw machine applications, the more finely operations can be divided, the faster the overall cycle time will be. This is why multi-spindle machines are so productive.

Breaking down the part production cycle into many very quick elements instead of a few longer operations results in faster throughput. For many applications on the mechanicals, secondary operations are necessary because there are not enough positions available to efficiently divide process into time-economic segments. With more stations (for example, ten or twelve are available on Magnum's rotary transfer machines), it's possible to do more operations on the workpiece in-cycle, which reduces or eliminates the need for secondary operations (see box).

Allocating People

Efficiency comparisons between the mechanicals and the rotary transfer machines include more than metalcutting. Mr. Skupnik puts it this way: "We can buy seven mechanicals for the price of a single rotary transfer machine. However, in our shop it takes three operators to take care of the seven mechanicals. On the other hand, one operator can run three of the rotary transfer machines. Our savings in labor alone quickly makes up the price difference. And that's before we add production advantages in bar stock magazine capacity and additional tool life. We're getting efficiencies for the rotary transfer that can hit 90 percent."

Magnum plans to automate the process even further with an automatic tool setter. This will be used to preset the cutters off-line so tool interchange—which is about all the operators need do on the rotary transfer machines—can be accomplished even faster.

An example of the production difference between the two technologies is a part that Magnum used to run on its mechanicals. "We ran three machines around the clock and occasionally added a fourth machine to keep up production," says Ms. Seidl. "We put the job on our Hydromat Pro 20 and now have a surplus of more than 150,000 parts."

This helps Magnum deliver on time to the customer while using the additional machine time available to run some other jobs. "In effect," she continues, "we gained new production capacity on three mechanicals and partial capacity on one rotary transfer machine simply by moving the part from one machine technology to another."

A Source And A Force

Magnum's technologies have led to a natural departmentalization of work. There are three key production areas within the company. Each is built around using screw machine technology that makes sense for the application.

The mechanical department provides parts that have less complexity, and therefore, fewer secondary operations. High volumes still move across these venerable workhorses, but have simpler, less exacting parts. "We've had offers for our mechanical machines," says Ms. Seidl. "We still have good use for them but we can now be selective about what runs across them."

More complex parts or parts which can be run two at a time are assigned to the Euroturns because of their efficiency gains. When the orders hit 100,000 and above, parts of sufficient complexity that would normally need secondary operations go to the rotary transfer machines to get processed complete.

Eggs In One Basket

Some changes that Magnum would like to make include getting a little

more diversified beyond automotive. "We'd like to get 25 percent of our business non-automotive," says Ms. Seidl. "The problem is that volumes are less in most non-automotive industries. That's part of our efficiency drive." Volume parts are what Magnum is known for. They get many orders from word-of-mouth generated by customers talking to other customers. They've been able to select work that fits the shop because there's lots of work. When that changes they plan to be ready.

Change Of Thinking

Moving from the traditional world of screw machines to the more sophisticated and significantly more expensive world of rotary transfer is a big shift in perspective for most shops. "It took us more than a year-and-a-half to transition from a typical screw machine shop mentality and to accept that these machines were, in total, cost competitive with what we'd used for years," says Mr. Skupnik. "Our thinking then was that for the price of one of these rotary machines, we could buy seven mechanicals. Why would you do that? We now know the answer to that question."

Related Content

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)