-

SPONSORED

-

-

-

-

-

MMS Blog

Finishing Process Extends Life Of Cutting Tools And Components

By applying compressive forces and abrasive media to cutting tools or workpieces, this surface finishing process improves component wear resistance and lubricity.

Read MoreToward More Seamless MQL

One of the small perils of a new technology is that it often involves new steps or new considerations that present special opportunities for error. Minimum quantity lubrication (MQL) is a technology that exemplifies this point.

Read MoreThe Value Of Daily CMM Capability Checks

Coordinate measuring machines are not infallible. A variety of factors can adversely affect their measuring accuracy, including a crash, large temperature fluctuations, a malfunctioning probe head, use of an uncalibrated probe - even a person leaning on the machine gantry might be enough to take it out of square. If the CMM's true capability is verified only once a year via laser or another calibration method, then it's possible that the CMM might be inaccurately measuring parts for an extended period of time, unbeknownst to the operator. The question remains - did a workpiece fail inspection because of an imprecise manufacturing process or an inaccurate CMM?

Read MoreA Study Of The Steady Rest

When the length and stiffness of a workpiece make it difficult to machine, many turn to the steady rest.

Read MoreThe Time Is Right For IMTS

Investing in the latest manufacturing technologies is one of the keys to succeeding in a global manufacturing marketplace. The time to do this is now.

Read MoreThe Power Of The Continuous Improvement Event

The continuous improvement event (CIE), called the Kaizen event by some, has proven to be a valuable tool for introducing positive change in an organization. Such an event targets a specific area in the organization where employees can work together to implement improvements quickly.

Read MoreAerospace Hole Making Takes Shape

The demand for fast hole making will intensify as more fuel-efficient jet engines are introduced. Electrical discharge machining is emerging as the answer.

Read MoreMainstream Technology Keeps Shop On Track

In its toolroom, Branchline Trains takes a practical approach to machining with end mills as small as 0.005 inch in diameter.

Read MoreChip-Free Drilling Process Creates Holes And Bushings

This chip-free drilling technique can create both a hole and support bushing in thin-walled parts in one machining operation.

Read MoreThe Real Cost Of Runout

A seemingly small amount of runout can still be too large for the tool. Reduce this runout, and tool life or productivity may dramatically increase.

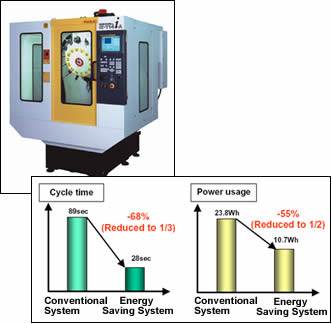

Read MoreCut Faster To Save Energy Cost

High speed machining and other control-related technologies offer real potential for reduced energy costs.

Read MoreAlcohol-Based Coolant Offers Environmentally Friendly Machining

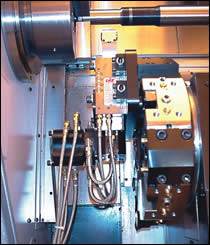

This micro-volume coolant delivery system uses ethanol as the cooling medium for non-ferrous workpieces. The ethanol evaporates after it cools the cutting tool, so no residue is left behind on machined workpieces.

Read More