-

SPONSORED

-

-

-

-

-

MMS Blog

Simplfying Thread Repair

Repairing damaged or worn threads on a workpiece is a common chore for toolroom lathes, especially in the oilfield industry. Haas Automation has a new feature for its conversational control units that simplifies and automates this process.

Read MoreCam Drive Allows Quick, Accurate 90-Degree Indexing

A design that combines a roller gear cam and Hirth mechanical-locking coupling allows this indexer to accurately position parts in 90-degree increments.

Read MoreEverything Changes

Through a sweeping transition to high speed machining, a Maryland contract shop realizes its goal of same-day, "in by 9, out by 5" turnaround.

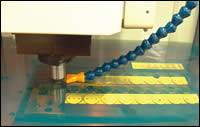

Read MoreCutting Tools For High Speed Milling Of Aluminum

Go with the flow—chip flow, that is. The uninterrupted flow of the soft aluminum chip determines the design of the end mills that Metlfab uses.

Read MoreAn Overview Of 3+2 Machining

An introduction to 3+2 machining: how it works and what it can do for your machine shop.

Read MoreInvolving Operators In The Maintenance Process

Every company is faced with the challenge of having too many things to do and too few resources to do them. Unfortunately, an important activity that often suffers from this lack of resources is equipment maintenance, or more specifically, preventive maintenance.

Read MoreTurning The Long And Difficult

This shop has made large turning work its specialty. In proving to its customers that it can perform this difficult work, it has started to win more "standard" machining jobs.

Read MoreTurning The Tide

When Briggs & Stratton decided to make the crankshaft machining lines in its Poplar Bluff plant globally competitive, it had to choose between CNC lathes and dedicated special machines for its main turning operations. The company chose the lathes.

Read MoreFor Laser Shops: Oxidation Retaliation

In an effort to prevent field paint failures, OEMs can no longer accept parts with the oxide buildup. A mechanical means of removal such as hand buffing or grit blasting is commonly practiced. However, these time-consuming and often labor-intensive processes can represent a substantial expense, and they can also introduce inconsistencies.

Read MoreWireless Collection Of Measurement Data

In manufacturing, reacting to measurement data in a timely fashion is critical. A fast response to undesirable trends can prevent scrap or rework. The problem is, it can be slow and cumbersome to collect, deliver and analyze measurement data. Recent efforts to expedite this process have included shop-wide cable networks with bar code readers and other automated devices. The latest development along these lines is wireless data handling.

Read MoreMove The Program Instead Of The Part

A complex five-axis part with hard-to-reach datums is machined in two setups instead of eight, thanks to a process that rewrites the tool paths to match the part's position.

Read MoreMaking Strides To Maximize Worker Efficiency

This 40-year-old shop combines original best practices with new technologies and manufacturing approaches to make the most of its home-grown skilled labor.

Read More

checks on machining line with Greg Hartwig.jpg;maxWidth=400;quality=70)