MMS Blog

Control Beyond CAM Unlocks Five-Axis Potential

Capabilities native to the CNC can facilitate levels of performance that would be impossible to achieve by relying solely on post processed part programs.

Read MoreWhy Tie Payroll Hours to Machine Hours?

The February 2018 digital edition of Modern Machine Shop covers topics such as machine monitoring, holemaking and tooling technology.

Read MoreIs Your Shop Ready for 3D Printing?

Andrew Tordanato of Diversified Manufacturing Technologies shares the questions to answer before adding 3D printing capability to your manufacturing operation.

Read MoreCybersecurity for Job Shops

Small and medium-size machining job shops can take steps to protect computerized or networked assets such as CNC machines from cyber attacks.

Read MoreThe Value of PVD Coatings for Medical Devices

Applying a PVD coating to medical devices can offer both aesthetic and functional advantages. Here are answers to some frequently asked questions.

Read MoreWhy Tie Payroll Hours to Machine Tool Hours?

J&R Machine uses machine-monitoring data not just to track machine uptime, but also to create a financial index that helps it shape decisions related to equipment, processes, staffing, sales and business in general.

Read MoreShop Hits Home Run with Toolpath Simulation Software

Wolcott Design Services needed to improve efficiency during high-mix, low-volume runs. HMCs and Vericut tool simulation software by CGTech improved efficiency, spindle utilization and revenue.

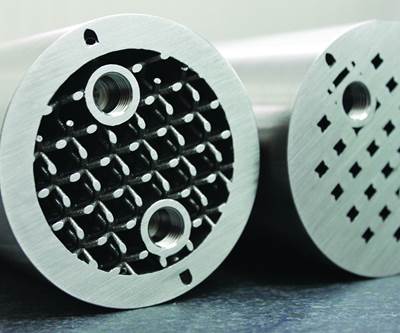

Read MoreLightweighting with Lattices

Instead of building components as a solid, building them as a network of unit cells may improve material utilization and performance.

Read MoreYour Chance to Affect Policy Change

Complete the U.S. Manufacturing Reshoring Study survey to provide politicians with insights into how much manufacturers offshore and what drives them to do so.

Read MoreWe Are Investing in the Print Magazine

We are doing so because our audience is there. Some findings suggest that’s not likely to change soon.

Read MoreBuying a Five-Axis: The Costs and Benefits of a Complex Machine

When considering transitioning to a five-axis machining center, it is helpful to understand the basics about the machines’ components, their costs and the opportunities they provide.

Read MoreTraceability Without the Paper Trail

A digital system makes it faster and easier to find, sort and glean insights from measurement tool usage and calibration data.

Read More