Share

Physical vapor deposition (PVD) is a vacuum coating process many shops know is commonly used to improve the performance of cutting tools. Mike Schultz, co-founder of Surface Solutions, says the cathodic-arc PVD coating services his Fridley, Minnesota, company offers can increase the life of a tool as much as 10 times compared to an uncoated tool by providing a harder, more lubricious and wear-resistant surface.

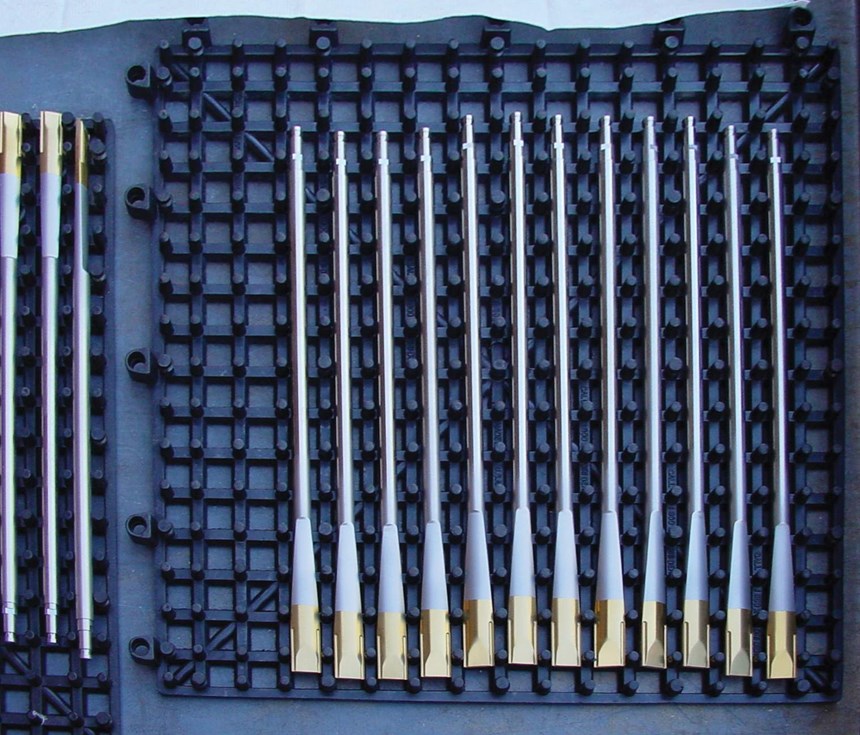

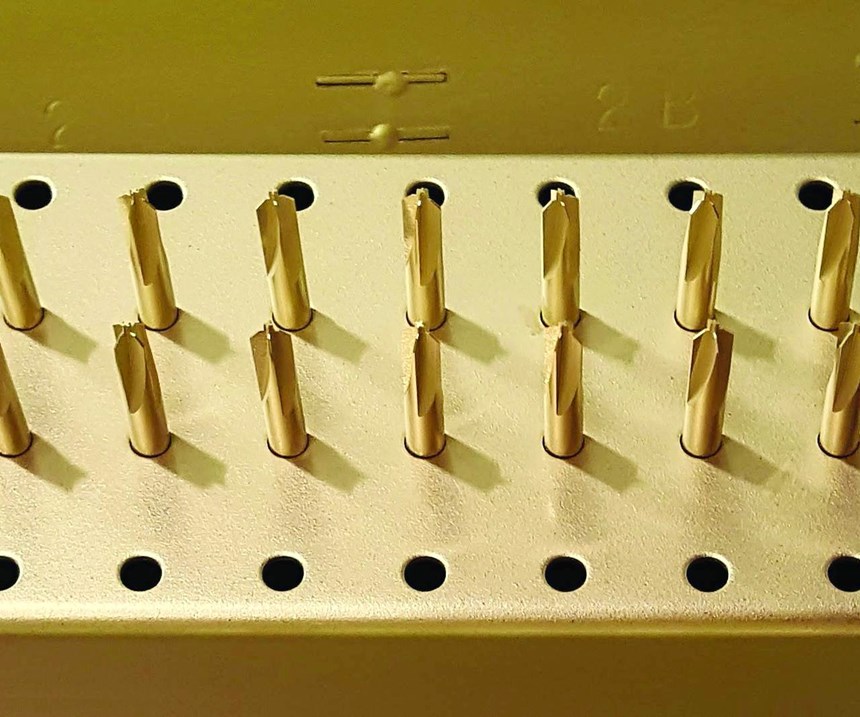

In addition, he says PVD coatings are being increasingly used by medical device manufacturers to differentiate the appearance of their devices from similar products and/or enhance their devices’ performance, being that the hard, inert coatings are biocompatible and don’t react with bone, tissue or bodily fluids. Examples of medical devices the company coats include distractors, drills and needles, but also “wear” parts used in various device assemblies as well as dental applications.

Mr. Schultz says PVD coatings offer improved edge retention so coated surgical instruments remain sharp. For other devices, they can reduce galling between mating stainless steel components, and help prevent oxidation and corrosion.

Here, he answers a few frequently asked questions about PVD coatings:

What is a cathodic-arc PVD process?

Cathodic-arc PVD is a process in which various metals are evaporated from a solid source material inside a vacuum chamber using an arc welder. The metals evaporated, such as titanium, chromium, zirconium, aluminum and various other alloys, are reacted with a gas (usually nitrogen and/or a carbon-containing gas) to form a coating material that condenses on the parts to be coated.

Cathodic-arc PVD produces high levels of metal ionization (more than 95 percent), which helps ensure high coating adhesion to the substrate material. The process typically has wide operating windows, making it possible to deposit quality coatings using a variety of process parameters. Other coating processes, such as sputtering or ion plating, are not as robust and have smaller operating windows, making it more difficult for them to consistently produce a quality coating.

What prep work is necessary prior to coating?

To achieve a well-adhered coating, it is very important that the parts to be coated are clean. Part surfaces must be free of oxides, EDM recast and organic films, because such contaminants can adversely affect coating quality.

To remove contaminants before coating, coating companies use techniques such as polishing, tumbling, acid etching, and sand and glass-bead blasting. Some of these techniques can alter the surface finish of the part being coated, however, so the coating company often works with the customer to develop a process that meets the customer’s expectations for coating quality and part appearance.

Are sharp edges adversely affected by the coating process?

If a part has sharp edges, cleaning processes that could adversely affect edge sharpness would not be used. Additionally, if tiny or very fragile parts are being coated, coating-process modifications can be made to reduce heat-up and coating rates. These modifications ensure that delicate features are not overheated and the coating is not too thick.

What surface finishes lead to the best results?

PVD coatings are very thin (typically ranging from 0.0001 to 0.0005 inch) and usually replicate a part’s original finish (unless an abrasive cleaning process is used). Best results are attained when part surfaces are smooth. As a result, ground or polished surfaces will often yield better results than bead-blasted or matte surface finishes.

If a matte finish on a specific area of a part is desired, it might be best to allow the coater to produce the texture on the part. Texturing by the part supplier could produce contamination on that area of the part, which would require some rework, negating any savings the supplier was perhaps counting on attaining.

What temperatures are used in the coating process?

Typical coating temperature for all Surface Solutions PVD coatings is approximately 800°F. Coating temperature can alter the hardness of parts or cause them to distort (shrink or grow). To minimize this possible effect, we suggest that heat-sensitive parts be tempered at 900 to 950°F before they are sent to be coated.

What types of materials can be coated?

PVD coatings can be applied to most metals that can withstand being heated to 800°F. Commonly coated medical materials include 303, 440C and 17-4 stainless steels; titanium alloys; and some tool steels. PVD coatings are typically not applied to aluminum, because the temperature of the coating process is close to material’s melting point.

What coatings are typically used for medical devices?

Surface Solutions offers four PVD coatings for medical devices. The most commonly used is titanium nitride (TiN), which has a thickness ranging from 0.0001 to 0.0002 inch, Vickers hardness ranging from 2,400 to 2,600 Hv, and a gold color.

The second most common medical coating is aluminum titanium nitride (AlTiN), often referred to as the black nitride or black titanium coating. It has a thickness ranging from 0.0001 to 0.0002 inch, hardness ranging from 4,000 to 4,200 Hv, and a charcoal-black finish.

Two other medical coatings the company offers are chrome nitride (CrN) and Alpha. CrN has a thickness ranging from 0.0001 to 0.0005 inch, hardness ranging from 2,200 to 2,400 Hv, and a silver finish. Alpha is a multi-layer coating that has zirconium nitride (ZrN) as the top layer and results in a silver-gold color. It has thickness ranging from 0.0001 to 0.0002 inch and offers the highest hardness, ranging from 4,400 to 4,600 Hv. The company says this coating can last two to four times longer than TiN due to its higher hardness, lubricity and abrasion resistance.

What advantages does PVD have over a chemical vapor deposition (CVD) coating process?

Compared to CVD, PVD coatings are applied at a much lower temperature, and PVD-coated parts don’t have to be heat treated again after coating. Also, PVD replicates the surface finish originally on the part, whereas CVD coating results in a matte finish, unless the part is polished after coating.

What advantages does PVD have over anodizing?

Surface Solutions coats titanium alloys and believes PVD is more wear-resistant than anodizing and retains its color better over time.

In addition to medical devices and cutting tools, PVD coatings are also commonly used to boost the performance and longevity of punching tools, forming tools and injection-molded wear components. Mr. Schultz says medical manufacturers considering PVD coating should discuss their projects with the coating company to ensure they get a functional coating on components where it is needed/desired with the best look possible.

Related Content

German Project Yields Three New Medical Machining Processes

Trends to Watch at IMTS: Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

Read MoreSchwanog Custom Form Tools Reduce Cycle Times

IMTS 2024: Schwanog’s insertable form tool system supports the manufacture of precision parts for industries such as medical, automotive, aerospace and others.

Read MoreKennametal Turning Tools Enhance Small Part, Medical Machining

TopSwiss Micro Boring Solid tooling and KCU25B turning inserts are well suited for the small parts and medical machining space.

Read MoreTungaloy-NTK PCD Grade Optimizes Dimensional Accuracy

The DX200 is an effective tool for machining application-specific components that demand high levels of material purity, such as metal medical implants and sputtering targets for semiconductor applications.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=300;quality=90)