Share

Takumi USA

Featured Content

View More

For Andrew Tordanato, Diversified Manufacturing Technologies president, getting into 3D printing was a natural evolution. His family owns Mohawk Manufacturing, a metal stamping operation that has been in business since 1921. In 2015, the company added a metal 3D printing division in response to changing customer demands. Diversified Manufacturing Technologies grew out of that experience, along with the desire to further “diversify” into plastics and carbon fiber reinforced polymer (CFRP) as well as metals. Things are coming full circle now, as Diversified not only prints parts but also helps manufacturers who are thinking about adding their own additive manufacturing (AM) equipment to their shopfloor operations.

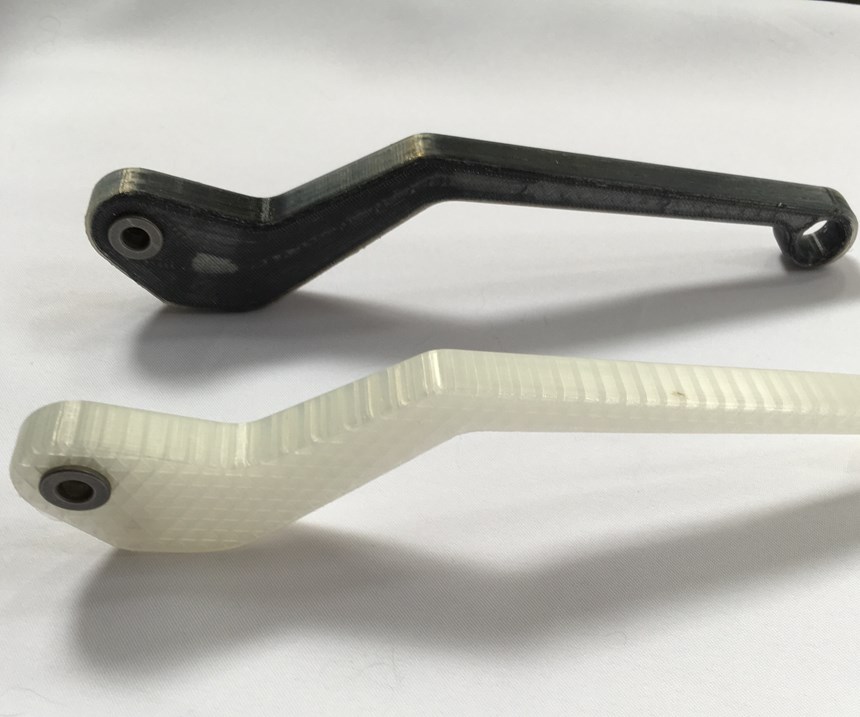

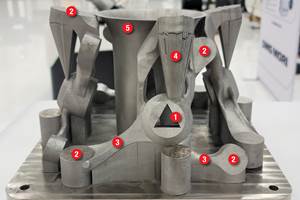

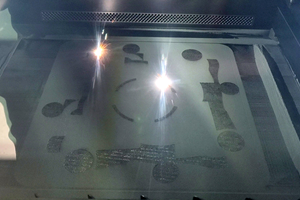

Today, Diversified Manufacturing Technologies manufactures parts for customers ranging from small job shops to large original equipment manufacturers (OEMs). The equipment at its Middletown, Connecticut, facility includes metal 3D printers such as a 3D Systems ProX 300 as well as half a dozen polymer 3D printers from MarkForged capable of laying a continuous thread of fiberglass, Kevlar or other fiber along with plastic filament to increase part strength. Diversified is also equipped with CNC machining and EDM capability, primarily used internally for finishing 3D-printed parts.

On the metals side, most of the company’s work is in prototyping, aerospace R&D and production parts, and short runs for the jewelry industry. With its polymer printers, the focus is jigs and fixtures, brackets, and short runs of items such as cases and handles. The work is often overflow for customers trying to meet tight production deadlines. Diversified is able to print parts on short notice, without the setup that would be required at a CNC shop.

Successful jobs often result in repeat orders and can lead to a better part design—converting a two-piece assembly down to a single 3D-printed piece, for instance. Sometimes customers go on to add their own 3D printers and bring production back in house. Recently, these types of customer relationships have led Diversified into consulting work to help companies decide whether to add 3D printing capability.

When working with a shop, Mr. Tordanato says there are three key questions he asks to help determine if the addition of a 3D printer is appropriate:

- What kinds of materials are you working with? 3D printers are compatible with a limited number of materials, so if a specific metal or polymer is required, that might sway the decision in one direction or another. However, an exact match is not always necessary, Mr. Tordanato says. For instance, carbon-fiber-filled parts made with the MarkForged printers can be strong enough to replace metal ones in the right applications.

- Is there flexibility in the manufacturing or design of the parts you make? In other words, does the way it’s made matter? In industries like aerospace, where process certification is important, there may not be flexibility to move a part from a machining workflow to a 3D printing one. On the other hand, parts with less stringent process or geometry requirements such as jigs and fixtures make good candidates for 3D printing, and could even be improved by additive manufacturing (think reduced weight and consolidated assemblies, for instance).

- What is the part’s end use? Shops don’t necessarily know the destinies of the parts they make, but this information is critical before transitioning work. Understanding the function of the part, where it will be installed and performance requirements is necessary to determine which parts are matches for 3D printing and which are not.

The answers to these questions will help determine whether a shop is ready for 3D printing based on the parts it currently makes, and if so, what type of AM equipment might be best. In many cases, shops can add polymer-based printers without needing any additional staff, Mr. Tordanato says (though he notes that metal systems tend to require deeper training and benefit from dedicated operators).

Of course, the specifics don’t matter unless the shop can answer the most basic question: Are you willing to change your thought process?

“The only way to take advantage of AM is to think additively,” Mr. Tordanato says. Initially that might mean identifying current parts suited to in-house 3D printing, but deciding when and how to implement AM is an ongoing process. To make the best use of the technology, shops should consider 3D printing as an option from the beginning of new jobs.

Related Content

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read More6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreDigital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;width=70;height=70;mode=crop)