MMS Blog

When Sophisticated CNC Machine Tools Aren't the Best Answer

As a machine shop owner, challenges come every day. Sometimes, relying on the tools you’re used to can keep you from finding more beneficial solutions.

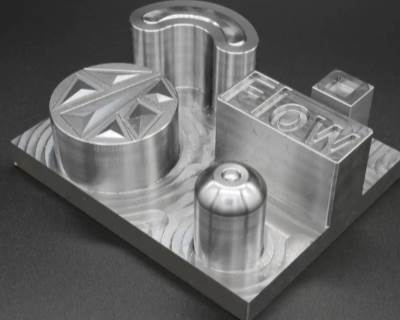

Read MoreFour New High-Performance Milling Techniques for 3D Machining

With many 3D milling applications demanding both shorter cycle times and smoother surface finishes, it’s time to review how you go about programming and machining parts. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes.

Read MorePortal Milling Machine Provides Years of Smooth Operation

Neuman & Esser uses their eight-year-old Droop+Rein from Starrag as a “workhorse” for complete machining.

Read MoreBold, Insightful Leadership Defines Manufacturer’s “DNA”

At its core, this highly successful contract manufacturer is a tool and die shop. Its founder, who has the heart and soul (and mind) of a tool maker, imbued his company with the values and the versatility of a tool room. This is his lasting legacy.

Read MoreAll Metalworking Metrics Continue Trend of Slowing Decline

The metalworking industry index signals decelerating contraction for a second consecutive month.

Read MoreLessons from a COVID-19 Shutdown and Reopening

Weldon Solutions, a manufacturer of CNC cylindrical grinders and robotic automation systems, had to close its doors for two months due to COVID-19. Now allowed to reopen, the company is taking stock of the lessons learned and a path forward during the pandemic.

WatchDie Makers Adapt to Challenges All Machine Shops Face

Die shops offer examples of adapting to the skills shortage and excelling at difficult machining. Plus, why reshoring should begin with die tooling.

Read MoreStandardizing on the Mazak Brand Eases Shop’s Training Process

Choosing a single brand of machine tools enables Ketchie Inc.’s operators to be self-sufficient. They can quickly learn to set up and program virtually any machine in the shop.

Read MoreRough Faster With Better Tool Life in Difficult Materials

Optimized roughing, also called high-efficiency milling, is an effective way to improve material removal rates and tool life for titanium and hard-to-machine alloys, but knowing when to use it is as important as knowing how.

WatchLarge Equipment Offerings Buoyed by New CNC

To complement the strengths of many of its larger machine tools, Tarus has added a Heidenhain CNC to benefit those manufacturers seeking high-quality contour surface milling capabilities.

Read More4 CNC Data Transfer Methods You Should Know

Modern CNCs enable transfer and backup of more than just machining programs.

Read MoreAn Unusual Machine for an Unusual Time: Mazak Helps AquiSense Fight COVID-19 with PearlSurface

When a company that specializes in rendering viruses and pathogens harmless via UV light looked to produce a portable disinfection device, it turned to its neighbor Mazak to move from design into production.

Watch