Rough Faster With Better Tool Life in Difficult Materials

Sponsored ContentOptimized roughing, also called high-efficiency milling, is an effective way to improve material removal rates and tool life for titanium and hard-to-machine alloys, but knowing when to use it is as important as knowing how.

Share

As new machining techniques become more widespread, it can be tempting for shops to try them out and put their promises to the test. It is important to not only learn how to use a new machining strategy, but how to make it the most effective for your application needs. Before testing out these new strategies, it is vital to learn when to use it and how to achieve the best results.

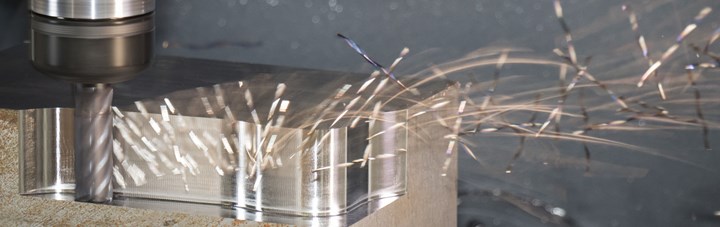

Optimized roughing is a machining strategy in which the full flute length of the end mill is used to improve both material-removal rates and cutting tool life.

Optimized roughing has achieved widespread use in much of the metalworking world thanks to its ability to improve tool life and feed rate. Known by many different names, including high-efficiency milling (HEM), it is an aggressive machining strategy that makes use of the full flute length of an end mill and light radial step-over to dramatically improve tool life and boost material-removal rates as high as 60%.

Typically, the depth of cut in an optimized roughing toolpath will be at least twice the tool diameter, making use of smaller radial stepovers to avoid generating too much heat with that depth. Despite the smaller radial stepover, the large depth of cut enables to cutter to remove material at a much faster rate with excellent chip control. The chip control is vital, as a constant chip load must always be maintained.

High-performance optimized roughing has also been seeing more use lately. Similar to HEM strategies, high-performance optimized roughing uses a larger radial stepover to increase the material-removal rate even further. Both approaches require robust tooling and advanced CNC controls capable of handling the intense forces and complex movements that are involved.

For both optimized roughing and high-performance optimized roughing, toolpaths are designed to maintain a constant angle of engagement in order to control the feed rate and chip evacuation.

The core benefit of HEM is simple: remove more material faster. However, the precise chip control of tools designed for it enables the user to control heat generation, making it ideal for roughing titanium and high-temperature nickel alloys. As an added benefit, this machining strategy provides more reliable tool life, thanks to both heat control and consistent engagement with the material.

However, no machining strategy is perfect for every challenge, and optimized roughing is no different. Here are some things to consider before you launch into optimized roughing.

What to Consider Before You Start

Does Your Part Benefit?

The first – and arguably most important – consideration is the part itself. Optimized roughing is extremely effective at achieving high feed rates, but only on prismatic parts with large, simple edges. The process is designed for making large, aggressive cuts quickly and efficiently, but a part with multiple complex features may not be the best choice, according to Seco Tools Product Manager Jay Ball. “When I look at a part, I look for straight walls and cavities that allow the use of the full flute length of the end mill,” Ball says. “This is a cutting strategy that is focused on high metal-removal rates, and parts that force you to reduce the depth of cut will necessarily force you to lower your metal-removal rates.”

Control heat generation in your optimized roughing operations with proper chip evacuation. This is especially important to do when working with difficult materials such as titanium and high-temperature nickel alloys to prevent hardening that can eat up your cutting tool.

Can Your Machine Handle It?

Optimized roughing is an aggressive machining strategy that involves a high feed rate with precise chip control. This means a shop needs to consider whether its machine tool can handle the intense forces and processing power necessary for optimized roughing. A spindle speed of at least 10,000 rpm is necessary, and more is recommended. Additionally, the machine must be exceptionally rigid, with a heavy-duty spindle. According to Ball, “For optimized roughing, the machine tool has to maintain rigidity in all aspects from the spindle to the ball screws.” This is a demanding process, and not just any machine can handle it.

Optimized milling is an aggressive machining strategy that can put a lot of strain on your machine tool. However, this strain provides excellent chip evacuation and material removal rates.

Can Your Control Process It?

In addition to a machine tool with high rigidity and a fast spindle, the CNC controller must have sufficient look-ahead capabilities to accurately maintain high feed rates. Most newer machine tools have these capabilities, which evaluate thousands of lines of code ahead of the spindle’s current position. This enables the machine to make complex adjustments in tight corners to maintain a consistent angle of engagement. “If the tool does not keep the angle of engagement consistent, you run the risk of scorching high-temperature alloys,” Ball says. “This can cause small areas of workpiece hardening, which is detrimental to both the part and to your tools.” Programming these kinds of tool paths by hand is nearly impossible, which makes the advanced CAM software absolutely necessary.

Optimizing Your Roughing Process

If you have the necessary machinery and processing power in your CNC, and your parts fit the bill, then it is time to think about how to set up a machine for optimized roughing. “Once you confirm that your machine can handle the process, the next step is ensuring that your tooling and fixturing are also up to the task,” Ball says. “At Seco, we recommend that the toolholder and workholding fixture are both extremely rigid, and we advise using end mills specifically designed to handle this process.”

Starting with the cutting tool, Ball recommends six- to nine-flute carbide end mills such as Seco’s Niagara Cutter Multi Flute family of products. The higher flute counts enable machines to achieve much higher feed rates when using the advanced toolpaths associated with optimized roughing, and the flutes themselves are designed to provide consistent chip evacuation, even when dry-machining difficult materials. According to Ball, “The most unique feature of the Niagara Multi Flute family of products is the advanced helical chip splitter design.” This innovative engineering enables unsurpassed chip control in applications requiring depths of cut up to three times the diameter of the tool. “Our Multi Flute mills are designed with HEM in mind,” he says. “From coating to flute, from geometry to edge prep, these are designed to make optimized roughing as efficient as possible.”

Multi Flute end mills like the Niagara Cutter family of products from Seco Tools are needed to maintain the constant chip load of optimized roughing.

Of course, your toolholder has to be as reliable as the cutting tool and machine. Runout should be less than 0.0004" for this process, according to Ball. “The thing to remember about Multi Flute cutters is that there are a lot of points of contact between the tool and the material,” he says. “That means there are a lot of points where the material pulls down on the cutter, so toolholders have to have anti-pullout capabilities.” The slightest offset can create nasty runout, so maintaining a firm grip on the tool is paramount. Ball recommends shrink-fit holders, high-performance collet chucks or milling chucks with anti-pullout technology.

Finally, the workholding has to be robust and rigid. “Every machinist knows that you have to keep your part still,” says Ball, “but this is an aggressive process that involves some very high forces, so it bears emphasizing.” Heavy-duty workholding is needed, as any shifting in the part could be disastrous.

For more information on optimized roughing, visit Secotools.com.

For more information on the Niagara Cutter line of Multi Flute end mills, click here.

To start increasing the productivity of your optimized roughing operations with Niagara Cutter solutions, contact Seco Tools at connect@secotools.com.