Die Makers Adapt to Challenges All Machine Shops Face

Die shops offer examples of adapting to the skills shortage and excelling at difficult machining. Plus, why reshoring should begin with die tooling.

Share

An example of a die maker significantly rethinking its processes and system is Otto Engineering. Find a link to our article about this shop below.

When I find myself in the position of explaining CNC machining to an outsider — that is, explaining what a machine tool is and how it connects to metalworking and manufacturing — I typically point to a metal component such as a car part to make the point that parts such as this are made by machine tools precisely cutting metal.

However, that explanation overlooks an important step. For many production parts, CNC machining makes the die tooling, and it is this die that makes the part. Given the variety and volume of parts produced through stamping, forming and other die-dependent processes, machining’s use in die making is an important aspect of the role machining plays. And an underappreciated one.

Indeed, die making is often underappreciated even when we give consideration to tooling. Because dies and molds are closely related, “die/mold machining” is routinely lumped together as a single category. But molds are most commonly associated with plastics while dies are for metal. Part of a younger industry and one that is still advancing more quickly, mold making is the flashy newcomer of the tooling scene.

Perhaps it is time for dies to get their due.

Recognizing this, we’ve recently posted a selection of pieces that reflect an appreciation for die machining. It is an appreciation that is well-deserved, as these posts describe how die making is leading the way in facing extreme versions of challenges that all machine shops confront.

One of these challenges relates to skilled personnel. How do shops deal with the now-familiar fact that employees with machining skill and experience are scarce? Consider: While machining skill is scarce, die making skill is rarer still. Otto Engineering responded to this fact by reinventing its process to use die-making specialists only where those employees can deliver the most value.

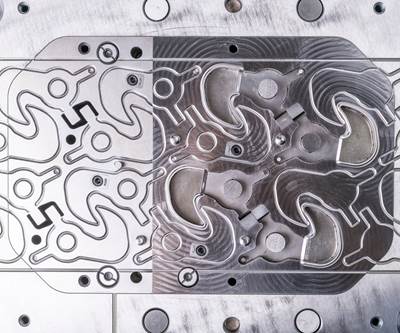

Then, there are the challenges of the machining itself. A die is an assembly of precision metal components that sees rigorous service — high forces at high frequency. Surface hardness is often a critical requirement. That hardness poses machining challenges for die makers equal to or beyond those of most other shops. Die maker and fineblanking specialist Feintool illustrates one response, describing the system it has found for not only achieving effective hard milling, but doing so within a process expected to run lights out.

Finally, there are important concerns around die making that are bigger than any shop. Our consideration of the topic now could not be more timely. As we’ve covered in recent issues, the disruptions of 2020 have turned attention to supply chain vulnerabilities and the value of reshoring vital manufacturing. Yet any discussion of reshoring must begin with tooling, the vital enabler to production that, over the last two decades, has increasingly been made overseas. A nation in control of its manufacturing must produce its own tools. We recently produced a video to bring greater attention to this very point: a discussion among experts making the case for the importance of domestic tool manufacturing. Watch that video, and please share it, because a very good outcome of a heightened appreciation for die making would be assuring that the U.S. remains strong and gets stronger in this capability.

Related Content

For This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

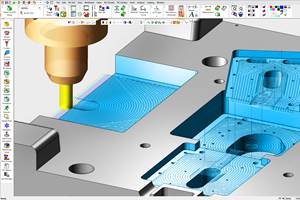

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

Video: The Importance of Reshoring Mold and Die Manufacturing

The die and mold tooling sector controls a manufacturing market more than 10 times larger than the market this tooling is used in. Experts discuss why the price savings of offshoring tooling misses the total cost of sending tooling work away.

Read MoreHard Milling Replaces Hand Grinding in Finishing Die Components

A focus on repeatability, geometric capabilities and speed led this manufacturer of fine-blanking machines and components to embrace hard milling as its go-to finishing process, eliminating hand grinding.

Read MoreUse Your Machinists to Make Dies

By systemizing die making into repeatable steps, Dies Plus, a division of Otto Engineering, is using its machinists to effectively make dies. This solution relies on a paperless color-coding system to convey the tolerances machinists need to hit in order for tool and die makers to do the final fitting.

Read More