Articles

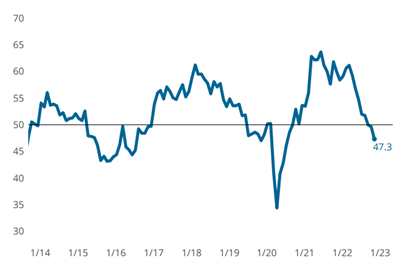

Metalworking Activity Contracted in November

Contraction was hard to dodge with metalworking activity expansion steadily slowing since March.

Read MoreDoes Metal Additive Manufacturing Belong in a Machine Shop? The Answer Is Mixed

Machining is a necessary capability for metal part production through 3D printing, but succeeding with metal AM demands a role and procedures much different from those of many machining providers.

Read MoreAutomation and Flexibility Counter Inflation at BI-MU 2022

Automation headlined BI-MU 2022, while flexibility underscored exhibitors’ products. These twin benefits may be shops’ greatest assets against inflation.

Read More10 Lean Manufacturing Ideas for Machine Shops

In addition to the right mix of traditional strategies, a lean manufacturing toolkit can make high-mix, low-volume machining faster, more predictable and less expensive.

Read MoreSaving Time and Money on the Shop Floor with AM

The ways additive manufacturing is presented sometimes miss the most practical and valuable ways it can be used.

Read More10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

Read MoreCutting Tool Inventory: A Big Concern for Small Shops

A job shop might have an amount of money tied up in tooling equal to a significant share of its investment in CNC machines. Here is how one shop owner thinks about tool management.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read More10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

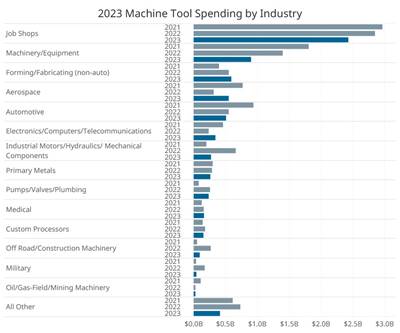

Read MoreMixed Bag Ahead for US Metalworking Economy

While what has been an extraordinarily robust manufacturing economy has softened in recent months, and the near-term outlook appears to be more of the same, the overall scenario remains strong. Even a possible recession next year does not appear to be an obstacle to continued growth over the next few years.

Read MoreGrooving Attachment Streamlines Operation by 75%

A grooving attachment enabled Keselowski Advanced Manufacturing to reduce cycle times by over 45 minutes on a high-value, high-nickel part feature.

Read More