Articles

Going Live on a Vertical Lathe

For this company, investing in live tooling and a high-pressure coolant system on a pair of new CNC vertical lathes eliminated setups, increased throughput and led to safer material handling on the shop floor.

Read MoreGetting into Gearing?

Gear designers and machine programmers/operators alike will benefit by attending this training course, where they will gain an understanding of gear noise dynamics.

Read MoreAutomated Coolant Concentration Management for Multiple Sumps

This system is capable of automatically managing as many as 10 machine sumps from one drum of chemical concentrate.

Read MoreSupply-Side Robotics

It’s not just the promise of automation that drives robot adoption, but also the cost of the technology. Will price declines bring about much more widespread use of robots in manufacturing?

Read MoreAdaptable Automation

A system for automatically swapping both workpieces and workholding enables a robot-loaded VMC to be quickly reconfigured for a new or modified job. The same system lets the robot change jobs in the midst of an unattended run. Thanks to the extra capacity from unattended production, the motorcycle part maker that developed this system has finally stopped shipping products late during the busiest part of its year.

Read MoreSecrets to the Art of Hand Scraping

Hand scraping of mating surfaces on a machine tool enables the surfaces to be flatter, more accurately aligned, longer wearing and freer to glide across one another. No automated or mechanical operation can match these benefits. Machine builder Okuma explains how this seeming paradox is true.

WatchComing Soon: New Duratomic

On April 1, Seco launches an upgrade to its well-known workhorse coated cutting tool line.

WatchCAM Software Enhances AWJ as an Additive Process

Intelli-CAM from Omax Corp is especially tailored for the needs of AWJ machine users. This CAM software provides features that support additive manufacturing applications.

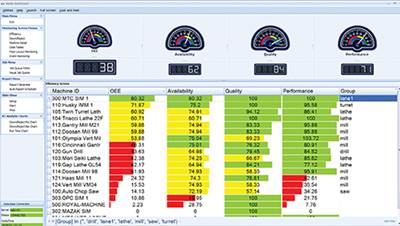

Read MoreMaking Sure MTConnect Is a Good Fit

An MTConnect-enabled machine monitoring system gives shopfloor managers information that is driving up utilization rates and improving workforce communication for this manufacturer of high-pressure aerospace fittings.

Read MoreMicromachining Tidbits

Here are a few tricks this shop uses to be more effective at micromachining.

Read MoreVideo: Compensating for a Bad Center Hole

Center hole drilled off-center? A compensating live center can save parts from becoming scrap.

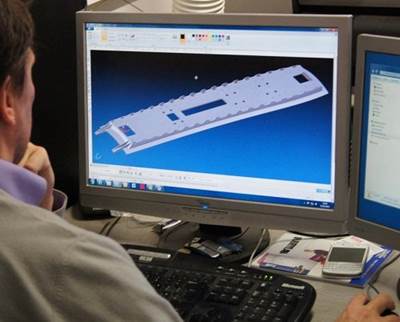

WatchBloodhound Fin Support Machined with Vortex

Machining strategy contributes to 40 percent cycle time saving on large five-axis aluminum part.

Read More