Adaptable Automation

A system for automatically swapping both workpieces and workholding enables a robot-loaded VMC to be quickly reconfigured for a new or modified job. The same system lets the robot change jobs in the midst of an unattended run. Thanks to the extra capacity from unattended production, the motorcycle part maker that developed this system has finally stopped shipping products late during the busiest part of its year.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreIf you think that the cyclical business conditions typical of machining work are a challenge, be thankful you don’t have motorcyclical business conditions.

Rekluse, the Idaho manufacturer of aftermarket dirt bike clutch components, gets the majority of its orders during the winter months. Order volume in any given February is generally two times the volume of the preceding August. Why? Because in winter, offroad motorcycle enthusiasts are dreaming about their bikes. They tinker with them during the shorter days to make improvements. During the rest of the year, they are busy riding. Rekluse thus has to deal with a dramatic annual cresting and falling of manufacturing demand.

The solution to the problem of that cresting demand would seem to be obvious. Why not make parts throughout the year, stocking inventory in preparation for the winter demand? Company owner and founder Albert Youngwerth explains why that solution doesn’t work. There are too many different part numbers, he says, and the company can never predict which product might see a surge in popularity. A particular clutch model appearing in a magazine profile of a celebrity motocross rider is the kind of event that drives orders. Plus, every year brings new bike models, meaning Rekluse has to design and introduce new part numbers to fit the new bikes. There is simply no way to plan ahead.

For years, the company hobbled along with two unsatisfactory responses to the varying demand. One was temporary labor. The manufacturing team of 10 to 12 full-time employees would be joined by six to eight temps for several months of the year. Lacking machining skills and a rooted understanding of the company’s business and processes, these temporary employees generally could not deliver anything like the value that a full-time staff member can, Mr. Youngwerth says. But what was even more problematic was the company’s other habitual response to the surge: It fell behind. Every year, Rekluse would frustrate or disappoint some customers by taking too long to ship orders.

The company owner says he knew automation was the answer. Or at least he thought he knew this. If his shop could meet the peak demand using automated equipment instead of additional staff, then perhaps it could afford to keep that equipment underused during the months that were slow. Doing this would certainly be less expensive than keeping people underused, he says. Yet when he engaged a manufacturing system integrator to engineer a robot-loaded machining process for one of his company’s part families, the price tag was too high for the company to be able to apply that same type of solution across all of the other parts. Also, by the time the engineering of this process was completed, the process was already obsolete. Thanks to product improvement plus modification for new bike models, the designs of the parts in this family had changed too significantly to be able to apply the automated system without costly reengineering. For Rekluse, the problem with robotic automation in machining was the inherently dedicated nature of the typical robotic solution.

He and other company team members looked for a way around this problem. They asked themselves whether there was a different way, a way for a robot used in machining to be more flexible. They asked, what if robot tooling could be changed as easily as vise-jaw tooling in the machining center? In fact, what if the robot used the vise-jaw tooling for its own gripping?

And that was the answer, he says.

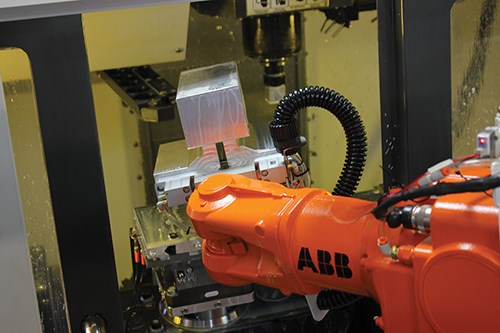

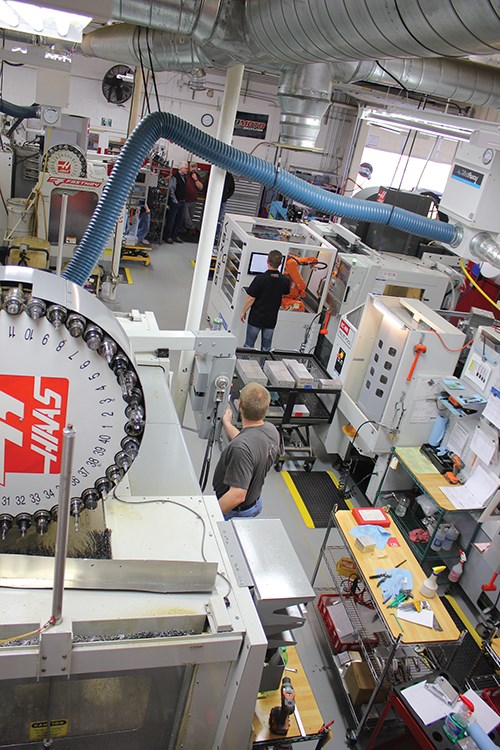

That idea—robot loading and unloading of the workholding that is used in the machining center—was the seed that has now flourished into a transformation of Rekluse’s process. Today, robots load both workpieces and workholding for seven different machining centers in the shop. In many cases, the robot changes jobs in the middle of an unattended run, as a planned part of that run, simply by switching to different workholding.

And that same seed has sprouted a spinoff. Mr. Youngwerth now serves as the president of VersaBuilt, a company he launched in the hope of bringing this same flexible robot system to other machine shops.

One believer is VersaBuilt’s first customer, Pro Moto Billet, which bought a VMC fed by the robot system instead of buying a new horizontal machining center. That company is considering phasing out horizontal machining, because the productivity results at Rekluse suggest that a robot changing fixtures on a VMC can deliver around 90 percent in-cycle time, which is greater than what Pro Moto typically achieves using a pallet-changing HMC. In fact, Rekluse itself has already taken this step, having sold its one horizontal.

But something even more significant than the productivity is the impact this productivity has had. This year, Rekluse hired two temps, not six to eight. And this year, Mr. Youngwerth says the company achieved a welcome and gratifying manufacturing milestone. Two winters ago, when the company had just one VMC loaded by a robot, it was still shipping orders eight weeks late. Now, there are seven robot-fed machines. And in this winter that just ended, he says, Rekluse made it through the busy season without ever falling behind.

Soft Jaws

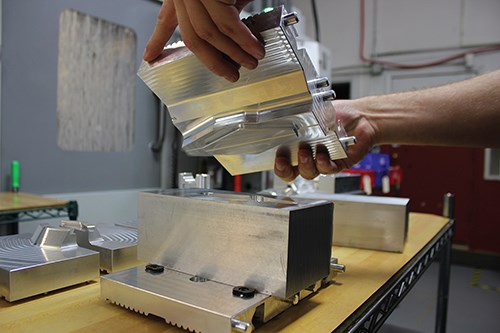

The essence of the VersaBuilt system is a simple idea. The robot loads and unloads vise jaws along with loading and unloading workpieces.

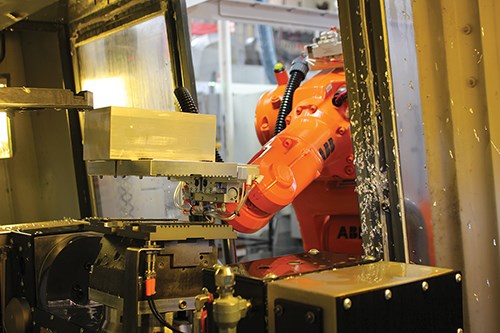

When he speaks of a robot machine-tending system often being “dedicated,” Mr. Youngwerth says much of what makes it dedicated is end-of-arm tooling. To the same extent that a machine tool needs workholding specific to holding a particular part, the robot also needs a gripper specific to holding that part. In the robot system developed by Rekluse and now marketed by VersaBuilt, the flexibility of this system comes from the fact that the workholding and the gripper are the same. Soft jaws—that is, vise jaws machined to match the workpiece—are pneumatically or hydraulically clamped into the machine-tool workzone, and these same jaws also pneumatically or hydraulically clamp to the end of the robot arm. The robot actually pulls out the soft jaws every time it pulls out a finished piece, because the robot uses these jaws to carry the finished piece and pick up the next piece from nearby shelves. When the system transitions to a different part number, it can do this by leaving these soft jaws within the same shelves, and going to a different spot on a shelf where it can obtain the different set of jaws for the next job.

Thus, what VersaBuilt sells is a system consisting of a robot (from ABB) surrounded by a modular shelving rack, along with software that makes it easy for the operator to assign particular workpieces and vise jaws to particular shelf locations.

What the company does not sell is dedicated tooling. Users of the system design and machine their own soft jaws as needed.

“Instead of selling them fish, we teach them to fish,” is the way company Director of Sales Brian Havey expresses it.

There have been challenges, Mr. Youngwerth says. The idea of loading workholding using a robot only sounds simple. Rekluse has spent nearly two years now on discovering and overcoming the challenges that stand in the way of this straightforward idea of loading parts by loading jaws.

For example, how to grip a part so that a soft-jaw-wielding robot can reliably place it on a shelf and extract it from that shelf is a challenge that, as it turns out, involves various nuances for different part designs. For parts machined in multiple operations, the machining strategy often has to be modified to prolong the grippability of the part from one operation to the next. Rekluse has become experienced at this.

And then there are the chips. Oh, there are the chips. Mr. Youngwerth says, “Ninety-nine percent of the time when we’ve had a problem that stops lights-out production, the reason is a stray chip.”

Probing has proven to be vital for addressing this. Production with the VersaBuilt system relies extensively on the machine’s resident probing capability to maintain reliable unattended production in an environment in which chips are flying. Cutting tools are probed not only to detect tool breaks during unattended machining, but also to ensure no chip is adhering to the tool. Meanwhile, workpieces are probed for flatness just after loading to ensure that no chip got trapped underneath the jaws, affecting positioning. And to ensure that a measured problem does not have to halt production, the system has algorithms and resources to respond. A part-wash station and an air knife are both within reach of the robot, allowing it to attempt to clean the part before it tries the same loading and probing again.

Finally, there are also external problems that do not stop productivity but instead derive from it. These can be surprising. For example, Rekluse’s ceiling is starting to sag. Machining centers are now doing so much continuous work that the increase in coolant mist being thrown into the air has made the shop more humid. Liquid is pooling in the fabric high above that covers the shop’s ceiling, causing various areas of dripping and droop. Rekluse personnel are still eyeing this problem overhead and speculating on what to do about it. In at least a small way, the sag is satisfying. It’s a result of increased production, and therefore a sign of success.

Back to Vertical

Lynn Hodges wants that same kind of success. His company, Pro Moto Billet, is also a motorcycle accessory maker, located in Nampa, Idaho, about 20 minutes from Rekluse’s facility in Boise. Pro Moto has just installed and begun to use the first commercially sold VersaBuilt unit, and in his application, he says the challenges and the debugging of this approach to automation will continue. He is ready for this. While his friends at Rekluse specialize in clutches, his company supplies a variety of accessories including linkage guards, footpegs, kickstands and cargo racks. The flexible robot comes from a shop in which many different machined parts all begin as identical circular blanks, but in his shop, he will run a variety of different parts with very different raw stock. In many cases, in fact, he will run a diverse variety of parts in a single unattended cycle with the VersaBuilt-tended machine.

Also, his machine tool is different. For even greater efficiency, Pro Moto will be the first to use the flexible robot with a VMC that features a dual rotary table for machining five sides of the part in a single cycle.

Pro Moto Billet transitioned many of its parts to horizontal machining about three years ago, Mr. Hodges says. He replaced three vertical machining centers with an HMC fed by a pallet pool, because the latter machine delivered greater productivity than those three previous machines put together. The HMC could do this because of its capacity to machine multiple parts in a single cycle (using a tombstone fixture), along with the capability the pallet system provided to let the machine keep cutting while the operator was staging or setting up a future job.

But now, if the VersaBuilt-fed VMC works to the extent that Mr. Hodges expects, he says his shop is probably on the cusp of reversing that three-year-old change. While an HMC can reduce the impact of labor by continuing to cut while the operator loads, a VMC served by the flexible robot can actually reduce the very need for labor by compacting the operator’s role.

On a horizontal, he says, the operator can never leave the machine for long. (Perhaps this is particularly true in his shop. Much of the work is aluminum, so cycle times are short.) A tombstone might hold six workpieces at once, he says, but still: As soon as the cycle is done, the operator has to again pick up the air nozzle to blow off the work, and again grab the wrench to unload six pieces and load six more.

With the flexible robot system, the operator’s role is much different. Given shelves that are full of all of the needed raw stock and all of the needed soft jaws, the automated machining system might run unattended for 24 hours. At the end of this time, the operator removes all of the completed parts from the shelves, then places blanks and perhaps exchanges soft jaws for the coming day’s unattended run, and changes out tools and performs other machine service as needed. In other words, all of the operator’s attentions are concentrated into a short period of time. The VMC is therefore much less demanding of labor than the HMC, says Mr. Hodges. It’s also less demanding of floorspace, because two of the robot-fed VMCs could fit into the footprint that is currently occupied by his pallet-pool HMC.

Prepare for the Peaks

For now, VersaBuilt is courting customers in Idaho, Mr. Youngwerth says. Until the system is more proven, he wants to keep its applications close. A local maker of food processing knives (yes, for potatoes) will install the system soon.

Once the system does have a more established track record, how widely could it be adopted? Certainly, there are limitations. Not all parts can be machined this way—the shelf system itself imposes a 4-inch limit on part height. And not all production applications are candidates. So far, the two users are aftermarket motorcycle part makers, companies facing the annual rise and fall in demand characteristic of this business. That rise and fall makes these shops different from other machine shops. And yet, not all that different.

After all, most other machining businesses are cyclical, too. The business cycle for a more typical shop might span many years instead of being compacted into one, but the nature of the problem is the same. A typical shop would likely expand its capacity if it could be assured of continuing strong business conditions for years to come, but it does not have that assurance. The expansion is therefore risky. The move would involve adding equipment and, more challenging, adding staff. Those added employees in particular are expensive to maintain if business declines, and letting people go is wrenching.

And here we come to the promise that Mr. Youngwerth hopes manufacturers will see. That is, he hopes they’ll see the lower-labor approach to production in the same way the cycle component makers see it: as a less expensive and less perilous way to expand potential capacity up to a level that matches the highest level of opportunity that the shop is likely to face.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreRead Next

Video: Robot Changes Vise Jaws for Continuous Machining

If a robot can load and unload parts, why can’t it do the same for workholding? Here is video of a robot changing the vise jaws so the same machining center can run different operations in unattended machining.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More