Bloodhound Fin Support Machined with Vortex

Machining strategy contributes to 40 percent cycle time saving on large five-axis aluminum part.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Five-axis machining may be challenging, but it’s not rocket science. Except when it is.

The Bloodhound is a 1,000-mile-per-hour rocket-powered car being developed to break the world land speed record, possibly this year. Though it’s named for a surface-to-air missile, the Bloodhound car will maintain missile-like speed entirely on the surface.

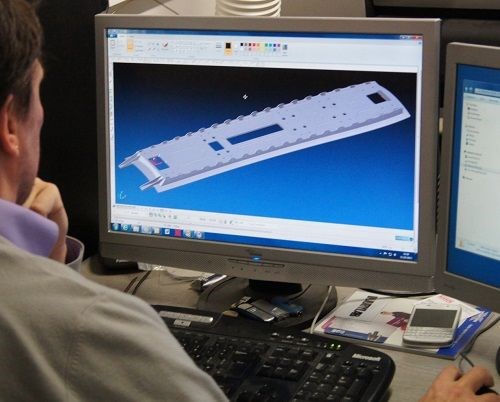

We’ve reported before on a leading-edge part made for this car. News of one of the latest examples of an unusual part for this car come from Delcam, whose PowerMill software and Vortex machining strategy figured into the five-axis machining of a tail-fin shear plate that will support the car’s large vertical fin at full speed.

The part shown on the screen in the previous image supports the car’s large vertical fin against the drag at full speed. Find images of the completed machined part posted here.

According to this BBC report, the aluminum plate—machined by Manufax Engineering on a Correa five-axis gantry-type—is more than 2 meters long by 400 mm wide, but only 2 mm thick in some places, and precisely curved to follow the contour of the chassis. An aluminum block weighing 750 kg was milled down to less than 9 kg to make this part.

Delcam says the combination of tooling from SGS and tool paths achieving efficient engagement through Vortex allowed the part to be machined with over 40 percent less cycle time than it would have otherwise required.

Related Content

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.jpg;maxWidth=300;quality=90)