Automated Coolant Concentration Management for Multiple Sumps

This system is capable of automatically managing as many as 10 machine sumps from one drum of chemical concentrate.

Share

Maintaining proper coolant concentration levels for machine tools extends cutting tool life and helps ensure quality workpiece surface finishes. That said, a variety of factors can cause coolant concentration levels to change from optimal. Evaporation during the day and carry-off can drive them up. Conversely, poor maintenance practices can cause them to become too low. In fact, low concentration levels is a major reason why coolant sumps go bad, according to Zebra Skimmers (Chagrin Falls, Ohio). Either way, without continuous attention, it can be challenging to consistently maintain proper coolant concentration levels.

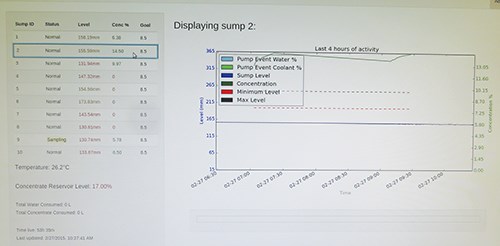

This challenge led Zebra Skimmers to develop its Dazzle automated coolant concentration management system, which is offered in two versions. Dazzle Island is a single-machine system, and Dazzle Archi is capable of managing as many as 10 machine sumps from one drum of chemical concentrate. The company says this is the only such computerized system capable of managing coolant concentration levels for multiple machines. These units maintain concentration levels to within 0.5 percent and can also determine the evaporation rate of each sump.

There are four primary Dazzle system components. The sump probe detects the level of fluid in a machine’s coolant sump and sends samples of sump fluid to the system’s refractometer. The refractometer is a continuous measurement device that views the fluid sample as it flows across its lens and communicates the measured concentration level to the system’s computer. (This process repeats for each sump monitored by Dazzle Archi.) When necessary, the computer communicates with all system devices to inject the correct amount of chemical concentrate into the system’s pump and add the appropriate amount of water. The pump then delivers the proper water or water/concentrate combination to the correct sump. One set of fluid lines can carry different brands of coolant, if necessary.

The company says this automated system results in cost savings on chemical concentrate, extends tool life and frees employees who would otherwise be involved in transporting, handling, measuring and correcting chemicals for each sump to perform other duties. In addition, machining speeds can oftentimes be increased, because the coolant concentration levels are consistently maintained at their appropriate levels.

Related Content

-

Vomat Coolant Filters Provide Precise Temperature Control

The company’s filters ensure a continuous supply of clean oil for microtool grinding applications.

-

Oelheld Coolant Increases Metal Removal Rates

The odorless coolant is said to offer increased removal rates, lower electrode wear, excellent surface qualities, lower refill quantities and longevity to provide lower overall operating costs.

-

Fortech Synthetic Coolant Enables Bio-Stable Metal Removal

Fortech’s TechKool FT4000 synthetic coolant is formulated to reject tramp oil that can cause smoking or misting and premature spoilage of coolant.