Articles

Infographic: Careers in Welding

An illustration summarizes the work, compensation and opportunities in this field. Those opportunities sometimes involve travel and increasingly involve automation.

Read MoreConnecting Forklifts to the Industrial Internet of Things

ITAMCO, a manufacturer of precision-machined components and high-precision gears, has linked its forklifts to its network-based communication system. This connection to the Industrial Internet of Things (IIOT) significantly reduces the time it takes to get material ready for the next operation.

Read MoreWhat’s “Cavaforming?”

Armed with a 40-foot-long, 40-ton cold-forming machine that’s long been out of production, this mold manufacturer can produce tubular insert IDs with ±0.0002-inch tolerances and a 4-micron surface finish without EDM or polishing.

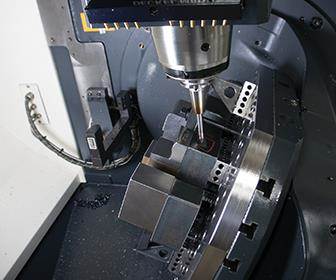

Read MoreTaking It Slow Pays Off for Learning Five-Axis Machining

A deliberately incremental approach helped this shop flatten a significant learning curve for collaborating on the postprocessor, easing setups and using cutting tools effectively.

Read MoreControl Capabilities Often Go Unused

The value of some control capabilities don’t become apparent until they are seen in use. Heidenhain supports its CNC users with a new Chicago-area training facility.

Read More“Smart” Generator Technology Makes EDM Operation Intuitive

GF Machining Solutions offers four generator features that enable users to input desired burning results into the CNC, and let the system do the rest.

Read MoreVariations on the Rotary Transfer Theme

A Hydromat open house event demonstrates the degree to which rotary transfer machines can be tailored to specific high-volume applications.

Read MoreEDM Cell Cuts Lead Time in Half, Improves Quality

Sodick's AG60L sinker EDM and an Erowa Robot Compact helped Ford Tool and Machining LLC cut lead time in half when it needed to reduce downtime and increase repeatability.

Read MoreIncrease Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

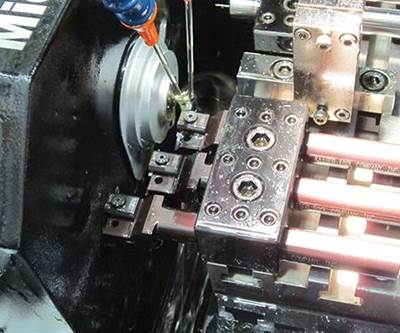

Read MoreMachining Micro Parts for Medical

This shop’s micromachining needs, primarily for medical components, ultimately led to the development of a new multifunction turning center platform geared toward producing tiny parts complete.

Read MoreA Virtual Approach to CNC Training

One way to take the fear of crashing an expensive machine out of CNC training is by using simulation software that features programming methods actually used on the shop floor.

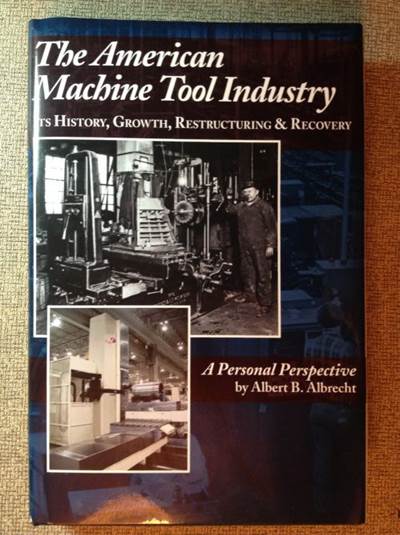

Read MoreA New Take on Machine Tool History

An enlarged, updated and revised edition of “The American Machine Tool Industry” by Albert B. Albrecht is now available. This new book includes a discussion and analysis of the industry's resurgence since the start of the new century, but retains the author’s personal but perceptive interpretation of its history when U.S. builders were the dominant force in the global machine tool industry.

Read More