EDM Cell Cuts Lead Time in Half, Improves Quality

Sodick's AG60L sinker EDM and an Erowa Robot Compact helped Ford Tool and Machining LLC cut lead time in half when it needed to reduce downtime and increase repeatability.

Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

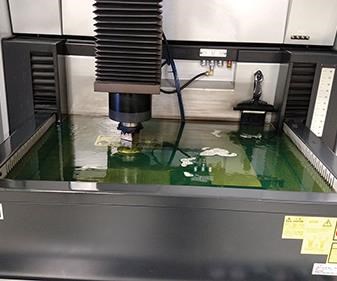

When Ford Tool and Machining of Rockford, Illinois, encountered a production bottleneck, it attributed its downtime and reduced repeatability to its sinker EDM. To wipe the slate clean, the company needed to be able to provide a steady supply of electrodes to its EDM to keep it running and producing more uniform parts. With a new AG60L sinker EDM from Sodick (Schaumburg, Illinois), and a Robot Compact from Erowa (Arlington Heights, Illinois), the company says it was able to dramatically improve its productivity, exceeding expectations.

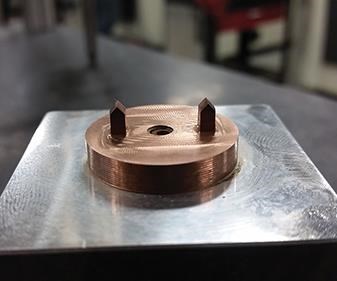

Since 1969, Ford Tool has been a supplier of carbide and high speed steel dies, molds, forming punches, and medical and aerospace parts. According to company President Thomas Chustak, the ISO-9001-certified shop is a supplier with diverse capabilities that upholds particularly high quality standards. For these reasons, it was necessary for any potential productivity solution to maintain the precise tolerances required by its customers.

Despite its range of machines—including two- through seven-axis CNC multitasking lathes, vertical and horizontal machining centers, a three-axis punch and pin grinder, wire and sinker EDMs, and more—the company’s reduced ability to utilize its sinker EDM quickly became a liability, and deliveries to customers grew increasingly late.

Together with a team of in-house EDM specialists, Mr. Chustak devoted a year to identifying and testing potential CNC equipment. After evaluating the cycle times, part finish and overall part quality of various machine tools, they ultimately decided to replace the existing sinker EDM with a new Sodick AG60L with an Erowa Robot Compact. In addition to providing improved cycle time and quality, Mr. Chustak says the machine’s 10-year accuracy guarantee made its durability stand out. To complement its capabilities, he selected the Robot Compact for the cell, because it presented the best loading, storage and pallet options, he says.

While the previous sinker EDM often sat idle as electrodes were manufactured, the new Sodick/Erowa cell enables the company to increase its output by 150 percent by automatically feeding electrodes into the sinker, he says. Since installing the cell, Ford Tool has not only stopped making late deliveries, but it also has reduced its lead time by 50 percent on all projects involving the sinker EDM.

In addition, Mr. Chustak says that the most important improvement has been unexpected: The company is able to hold tighter tolerances and produce a consistently high surface finish.

One way this is accomplished is through Sodick’s rigid linear motor technology. The AG60L sinker EDM achieves axis speeds ranging to 1,440 ipm and rapid acceleration ranging to 1.2 G. At these speeds, axis movement creates its own flushing conditions. The high speeds of this no-flush system effectively blow out any chips, gas or tar that remain between the workpiece and the electrode, enabling operators of all skill levels to produce a part finish that is 10 to 15 percent better than the company could previously achieve, Mr. Chustak says. Moreover, the positioning accuracy of rigid linear motor technology ensures two to three times greater accuracy than the previous sinker EDM, he adds.

Sodick’s rigid linear motor technology uses flat, uncoiled servomotors. As amperage enters the coils, it creates a force that is repelled directly against the magnets, eliminating the need for ballscrews. By eliminating the mechanical-drive components, rigid linear motor technology eliminates friction, vibration and thermal distortion, resulting in greater accuracy at higher speeds.

Productivity is also boosted by the Robot Compact’s slim two-by-one monoblock design, which enables it to fit well into Ford Tool’s workspace with a minimal footprint. Despite the small size, however, the Robot Compact still offers more than 200 magazine positions, providing more hours of production with less downtime. In addition to automatic tool changing functions, the robot also performs automatic changes of the workpieces. By changing both electrodes and workpieces, the robot frees additional manpower for other tasks. This autonomy is further bolstered by Erowa’s automatic gripper change, which ensures that the appropriate robotic gripper is used for the pallet size being used. Together with the AG60L’s high-speed machining, the cell makes it possible to yield more accurate parts at a greater speed with greater operational hours.

Ford Tool further minimizes downtime by utilizing an electrode milling center, which is also compatible with the Robot Compact. In this way, the robot’s magazines can be filled as quickly as the electrode machining center can produce replacements. Thus, the manufacturing cell enables seamless automation from electrode manufacturing to storage to tool change to workpiece change.

Ford Tool says it is projecting substantial growth in the upcoming months because of the new manufacturing cell. Thanks to the improved productivity and accuracy, Mr. Chustak is looking to take on new business that would have been impossible in the past.

“We’re considering bidding on different types of work that we would not have been able to produce before,” he says.

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)