A New Take on Machine Tool History

An enlarged, updated and revised edition of “The American Machine Tool Industry” by Albert B. Albrecht is now available. This new book includes a discussion and analysis of the industry's resurgence since the start of the new century, but retains the author’s personal but perceptive interpretation of its history when U.S. builders were the dominant force in the global machine tool industry.

Share

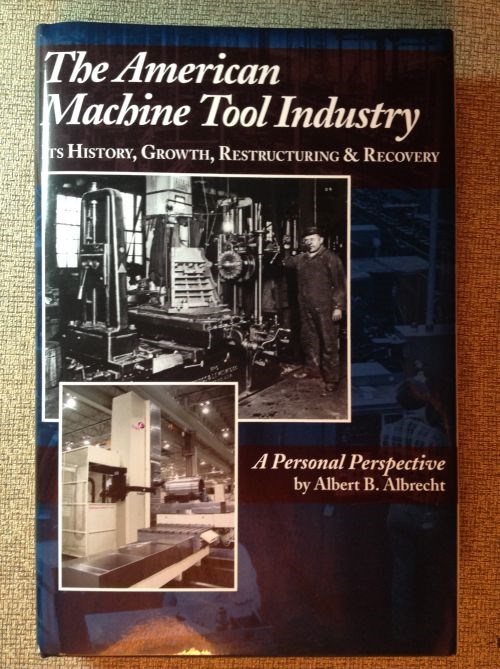

Albert B. Albrecht has a new book out and it is a good one. It is an enlarged, updated and revised edition of his book “The American Machine Tool Industry,” first published in 2009. The original title has been retained, but the subtitle has been changed from “Its History, Growth and Decline” to “Its History, Growth, and Restructuring & Recovery.” Mr. Albrecht’s discussion and analysis of the industry’s current resurgence are chiefly what makes this new edition different and worth buying to replace the earlier editions. You’ll find the bulk of this enhanced content in the last 60 pages or so.

Here, Mr. Albrecht focuses on the positive changes and developments in the industry that have occurred in the first part of the 21st century. The main message is that machine tool building in the United States is alive, well and gaining strength (although serious challenges and obstacles persist). The author is apparently reconciled to the fact that many of the machine tool factories that are growing and prospering in this country belong to builders based overseas. It is also apparent that he is quite gratified that the machine tool factories belonging to U.S.-based builders, such as Haas Automation, are as advanced and productive as any in the world.

Of the seven chapters in the new section, the two most interesting are 20: Machine Tool Builders of the 21st Century and 21: Machine Tools of Today & Tomorrow. The former includes short profiles of builders whose outlook and capability exemplify the state of U.S. machine tool building. Mr. Albrecht pinpoints what he says are the keys to their success: a clear-cut corporate purpose, a strong sense of identity and values beyond just making a profit. The following chapter presents a sample of advanced machine tools that characterizes the current level of metalworking and metalcutting technology.

The next two chapters reiterate the commonly held notions that the biggest hindrances to the American machine tool industry, and to manufacturing in general, are unenlightened public policy (mainly misguided tax laws) and the shortage of skilled workers. The fixes that he endorses for this shortage are projecting a “cooler” image for manufacturing and reviving traditional apprenticeships.

My positive comments in the review of the first edition of Mr. Albrecht’s book still apply to the preceding sections of the latest version. His history of the industry comes to life in his personal accounts of what he observed and learned as an engineer, then a manager, during the “Golden Years” of U.S. machine tool building when it was the dominant force in the global industry. This period, he says, lasted from 1948 to 1998. The color illustrations added throughout the book are especially complementary to the vivid descriptions in these historical chapters.

I found this latest edition to be better organized and easier to follow than prior editions, yet it retains the intensity and earnestness of the original work. As in the prior editions, however, you will have to overlook some pesky lapses in proofreading and copyediting.

Anyone interested in machine tools and the history of manufacturing technology as told from an insider’s perspective should own this book. I wish a copy could be given to every young person entering an educational program related to machining, manufacturing or engineering. I would tell these recipients that reading it cover to cover right away may not be the best way to absorb the value of this book. Instead, I would recommend that they page through it every once and a while as they learn more about technology and develop their manufacturing skills. Each time they did this, they would be reminded of the tradition and promise that still inspire careers in manufacturing. And each time, they would find facts, comments and lively stories that impart a greater significance than they were able to perceive the time before.

In my 2010 review, I said Mr. Albrecht’s original book represented a fitting “closing act” in his long career. I’m glad I was wrong about that. I hope further encores in perceptive writing by Mr. Albrecht still lie ahead.

To obtain a copy, write to Albert B. Albrecht, 3290 Toddsbury Lane, Richmond, Indiana 47374. Thanks to support from AMT-The Association For Manufacturing Technology, the cover price of this new edition has been reduced to $32. Shipping by priority mail is $7.50. You can also reach the author at albertalbrecht@frontier.com.

Related Content

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)