Articles

Fending Off Spindle Failure

In addition to offering seminars on spindle preventative maintenance, GTI Spindle Technology also has a portable vibration analysis unit that can be operated via a tablet app.

Read MoreMore Effective Deep-Hole Drilling with MQL

A dual-margin design enables a series of drills from Nachi to create holes with large length-to-diameter ratios with minimum quantity lubrication.

Read MoreMTConnect Is Commitment

Moving to the Industrial Internet of Things is an urgent strategic goal, but on the shop floor, tactical deployments will require MTConnect-enabled systems. The [MC]2 Conference provides a battle plan.

Read MoreStandardized Parameters Make Unattended Machining Reliable

Standardized parameters for specific material and cutting tool combinations help this hard milling specialist manage a highly varied workload with minimal labor.

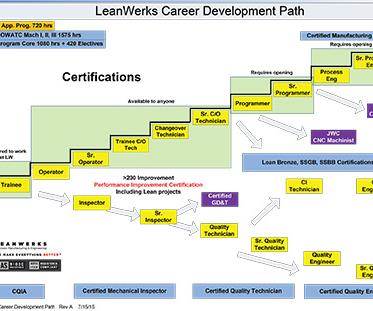

Read MoreShop's Own Training Program Paves a Pathway to Employee Success

This shop developed a Web- and video-based training program tailored to its own specific practices that enables new hires to progress in stages from trainee to senior process engineer after demonstrating a clear understanding of each new skill they’ve acquired.

WatchThe Benefits of Horizontal Turning on a Mill-Turn Machine

A mill-turn machine that can rotate a large, bell-shaped workpiece in a horizontal orientation enabled this manufacturer to hit tight tolerance and cost targets. Minimizing non-value-added time and running lights out were also essential for success.

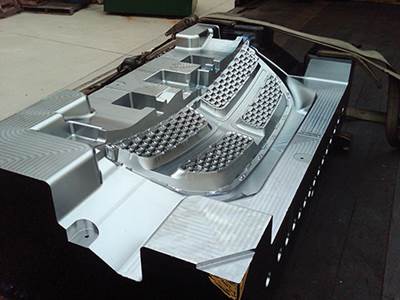

Read MoreKeys to Success in Unattended Hard Milling

MMS first visited this shop a decade ago to investigate the requirements for an effective hard milling process. We recently returned to explore the system in place for ensuring that process is reliable and predictable enough to run unattended, often for days at a time.

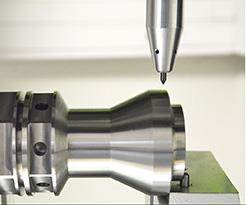

Read MoreContour-Following Stylus Speeds Dot-Peen Marking

Capability to mark surfaces at widely varying heights and difficult-to-reach areas makes pneumatic systems more competitive by reducing the need for special fixtures and other accessories.

WatchFive-Axis Machining Complements Additive Manufacturing

Intricate components made through laser melting go directly to a five-axis machine as part of a service combining additive and subtractive processing.

Read MoreCloud Computing’s Robotic Implications

Eliminating the need for individual robots to perform complex calculations on their own could facilitate the development of systems that are not only more sophisticated, but also cheaper and more accessible.

Read MoreAdditive Manufacturing Training Center Opens in Louisville

The UL Additive Manufacturing Competency Center provides training for beginners through advanced AM users.

Read More