Machining Micro Parts for Medical

This shop’s micromachining needs, primarily for medical components, ultimately led to the development of a new multifunction turning center platform geared toward producing tiny parts complete.

Share

It’s sometimes hard to tell what a shop is all about just from its name. That’s not the case with Medical Micro Machining. The Colfax, Washington, shop specializes in producing prototypes and small batches of very small components, with work for the medical industry representing 70 percent of its business (the balance is largely for electronics and microwave system applications).

Rob Whitmore, company president, says the two primary challenges the shop currently faces in serving the medical, as well as electronics, communications and other industries, are shrinking size specifications and atypical materials that are becoming more exotic.

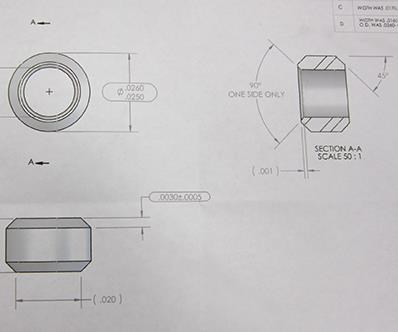

How small is small? Consider the part drawing shown below. This tube part has a length that can be no longer than 0.170 inch, an inner diameter that can be no larger than 0.0160 inch, an outer diameter that can be no larger than 0.0260 inch, and tiny inner and outer chamfers.

What kind of atypical materials are required? Some parts call for bio-absorbable plastics, plastics with magnetic properties, tungsten-copper, titanium and so on.

These fundamental challenges have shaped the type of equipment the shop has added over the years and the processes it has developed to machine parts that might have tolerances as small as ±0.0001 inch. In fact, it ultimately led to the design of a new type of micro-turning machine platform that the shop uses in conjunction with Swiss-type lathes to perform turning, milling and drilling with the goal of machining micro-sized parts complete from barstock in one setup.

Small Stuff from the Start

After working for nearly 20 years managing other manufacturing companies, Mr. Whitmore started Medical Micro Machining in 1994, along with his wife Kathy and partner Ed Freer, in Simi Valley, California. There were two sides to Medical Micro Machining at that time. Mr. Freer concentrated on producing and selling his line of AM-2000 micro-turning centers, while the Whitmores managed the contract machining portion of the business.

Mr. Whitmore says what jump-started the contract machining business was developing a process to machine medical bio-absorbable bone screws made from plastic material that degrades over time. At that time, this material could not be produced via injection molding. It has a melting point of approximately 140°F, so Mr. Whitmore designed a machining operation that used liquid nitrogen to freeze the material as it was being machined. The contract machining business began to steadily grow after that, with the shop being asked to produce parts in various other challenging materials as well.

When Mr. Freer passed away in 2000, the Whitmores decided to focus the company solely on contract machining. In 2007, they moved the business to Mr. Whitmore’s hometown of Colfax. The shop continued using some of those original AM-2000s, but began looking for alternate equipment when those machines started to break down more frequently.

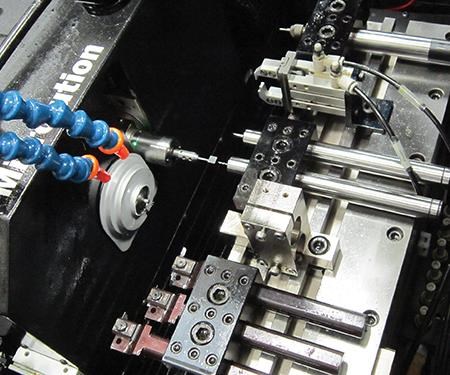

Mr. Whitmore says that at that time he couldn’t identify other machine models similar to the AM-2000s. However, after discovering micro-milling and laser machining equipment produced by Microlution (Chicago, Illinois), he approached the machine tool builder with the idea of creating a micro-turning machine akin to the AM-2000. After a few years of development, the result was the Microlution four-axis MR-4 gang-tool-style micro-lathe that offered a variety of features that makes it well-suited for effective turning, milling and drilling of very small parts.

Medical Micro Machining was the beta shop for this new machine line and has the first four models that were produced. These compact machines have a 10-inch polymer concrete base that is said to absorb vibration 20-times better than steel. The X- and Y-axis tool stage and Z-axis spindle stage are mounted atop the base and provide 1-micron position accuracy. The machines offer an XYZ working volume of 11.81 by 4.92 by 5.91 inches and accept barstock to 5/16 inch in diameter.

Mr. Whitmore says two important features of the machines are automated tool setting via a Blum touch probe and Y-axis movement. The touch probe can automatically measure tool lengths, which greatly reduces setup times compared to manual methods. This capability is especially valuable for shops such as Medical Micro Machining that primarily perform prototyping and short-run work, which requires frequent setups compared to high-production jobs.

The probe can also be used to precisely set a tool’s Y-axis position to within 0.0001 to 0.0002 inch of the workpiece centerline. While a shop performing work on larger parts might be able to get away with being off here by a couple thousands of an inch, in Medical Micro Machining’s case, that’s the size of some of the parts it machines.

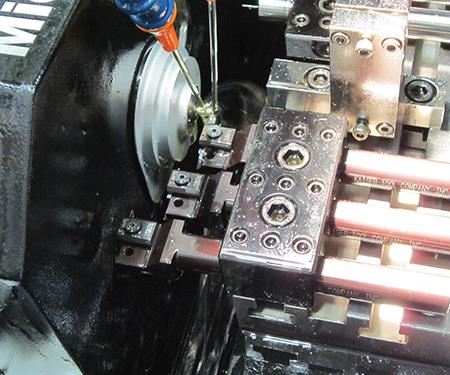

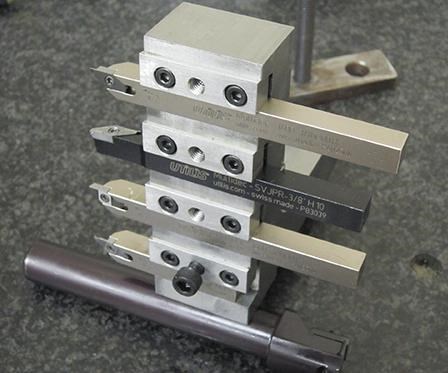

Mr. Whitmore says the Y-axis also enables as many as four stick tools to be stacked in a single holder, each able to be touched off during setups using the probe. The shop has also had as many as five live-tool spindles installed on the gang plate to perform milling and related operations. After each part is machined, parted off and dropped into an automatic parts collector, a pneumatic bar puller installed on the gang plate automatically pulls a fresh portion of barstock into the workzone for machining of the next part.

The MR-4 machines also have an integral video camera with 13x magnification and a dedicated monitor. Mr. Whitmore says this proves beneficial during setups, especially when very small tools are used or if the setup is unusual in some way. Machining operations can also be observed in real-time. Although this isn’t as valuable when coolant is used, it can be when dry-machining parts such as plastics. That way, the operator can see if a drill is off-line a bit and wiggling, determine why odd marks are found on completed parts, and so on. It’s the same when dry-machining brass, a material the shop sometime uses to initially dial in a setup for jobs that call for a more costly and exotic metal.

Because these particular machines have a 5,000-rpm spindle speed, cut data for tools that might otherwise be run at higher speeds must typically be dialed back, Mr. Whitmore explains. That’s where the shop’s experience with machining small features in odd materials pays off, as it essentially halves the cut data until reaching values appropriate for the available spindle speed.

This can mean milling passes must be taken using a very shallow depth of cut. Mr. Whitmore offers the example of a tungsten-copper part that required 0.250-inch-long grooves that were milled using multiple passes with a 0.001-inch depth of cut. However, the MR-4’s fast rapid traverse speed and 2G acceleration can quickly retract the tool and start the next pass, helping to reduce overall cycle times.

A Shop Divided

Medical Micro Machining’s facility is divided into two production areas, one where dry machining is performed (primarily for medical-grade plastics that can be easily contaminated) and the other where mineral-based oil coolant is used. Currently, two of the MR-4 machines are located on the dry side and the others are on the wet side.

Most of the work the MR-4s run on the dry side is machining plastic tube capsules used for a medical device. The capsules previously required polishing after turning so they would be optically clear. However, the use of diamond tooling and a turning process that Mr. Whitmore was tight-lipped about has eliminated the need for a secondary polishing operation. The end caps for those capsules are also produced in that area on one of the shop’s remaining Freer AM-2000s. In fact, the shop commonly machines caps using remnants from the bars run on the MR-4 machines, meaning it ends up using 95 percent of each costly bar.

In addition to an MR-4, the wet side also includes a few Swiss-types, including two Tornos Deco 10 machines and a Tornos Deco 10a. The shop uses this machine for very small parts, too. The decision whether to use the MR-4 or the Swiss-types largely depends on the batch size. If a run calls for only 1 to 1,000 pieces, those parts will likely be produced on the MR-4, because setup times are faster. Conversely, it might make more sense to set up a Swiss-type when batch sizes are higher than that. In some cases, though, the shop might set up prototype work on a Swiss-type if it’s fairly clear that a healthy production run for that part might follow.

In fact, the Deco 10a machine is fitted with a unique parts collection system for tiny components that the shop designed. As a component is parted off of the barstock, a vacuum system pulls it through a tube routed through the machine and into a fine-mesh basket.

New Machines on the Horizon

The four MR-4s at Medical Micro Machining represent Microlution’s original design for that micro-turning platform. The machine tool builder has since modified the design based on Mr. Whitmore’s input and is producing a second-generation model with improvements such as a 15,000-rpm spindle and a FANUC control. Mr. Whitmore says he plans to acquire one of these new machines to take the place of one currently used on the facility’s wet side (that older one will be cleaned and transferred to the dry side). The shop also plans to upgrade its inspection capabilities, given that measuring micro parts can be as challenging as machining them.

Related Content

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read More3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)