Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

Share

Bryan Machine Service cannot afford to have parts wait in line for finish-machining. This is why, when Modern Machine Shop last checked in, the Huntington, Ind., job shop had recently implemented a method for milling with air on its VMCs. More specifically, the shop had designed and built its own air-driven spindle to achieve the high speeds required for its most intricate work: namely, graphite machining and small rubber and plastic molds with as many as 200 cavities. Now, the company is doubling down on this strategy with a new, twin-spindle design that enables milling two parts at the same time.

Bryan Machine Service’s VRT high-speed spindles are driven by the shop’s compressed air system rather than by the spindle motor of the machine tool. Although this configuration limits torque, higher speeds are ideal for taking light cuts efficiently. “The advantage [of milling with air] is that the rpm can go much higher than standard CNC machines,” says shop owner Steve Bryan. “A standard CNC can now get up to 12,000 rpm, but with small tools — 1/16 inch or smaller — you need to be in 30-40,000 rpm range.”

Despite the heightened rpm provided by its air-powered machines, the shop still experienced production bottlenecks as parts got to the finishing stages. Bryan had been incubating a twin-spindle design of the VRT for some time, but the pandemic provided the time to make the concept a reality. “We did a lot of work for ourselves,” Bryan says, “a lot of which was on this twin spindle and the prototype build.”

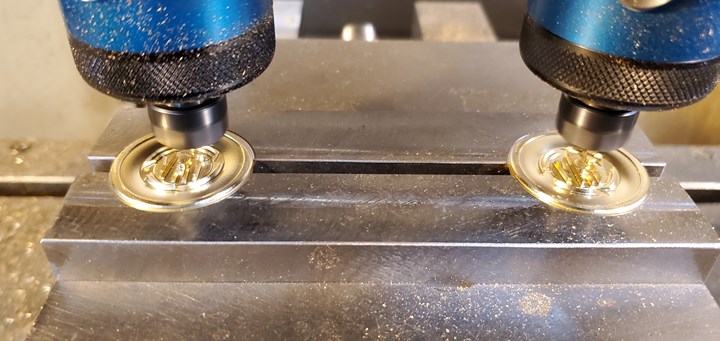

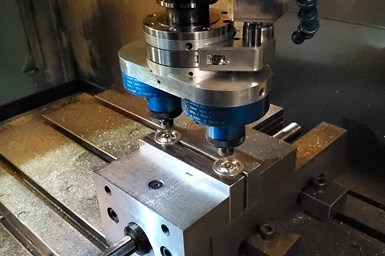

The VRT twin spindle is capable of machining two parts on the same shank simultaneously. Photo Credit: Bryan Machine Service.

Mounted on an indexable, rotary baseplate, the VRT twin spindle effectively doubles the shop’s output of small parts by enabling one machine to run two parts at the same time. The two spindles can simultaneously manufacture two parts on a single shank, as long as the parts are separated by four inches.

Spec-wise, the twin spindle is nearly identical to the single-spindle version, aside from the air consumption being considerably higher. One new addition is an air wash in the coupling mechanism that sprays a burst of air to clear debris or through-coolant before coupling. The coupling mechanism also adds a rotational break that mechanically locks the spindle in place once it couples. The system has been adapted to nearly all the machines that Bryan Machine Service runs and, as Bryan says, it is used for “just about any operation that has long cycle times and small tools.”

Bryan Machine primarily uses the twin spindle to engrave parts that have already undergone roughing with a larger, single tool. The twin spindle enables the shop to get parts done faster than“waiting on a machine and having people come back late at night to pull a part out and put another part in,” Bryan says. “We don’t have to do that anymore or buy another machine to keep up.” The shop can now double its production of small parts — even when the lights are out.

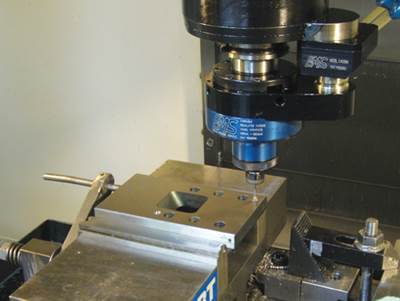

While the shop has drastically increased production with the twin spindle, it had to overcome a number of design hurdles with the indexable base to get things up and running. Bryan says most of the work came from designing the indexing base to be able to rotate while still receiving the same air supply and coolant flow through the rotating coupling. The final version of the rotating base, when coupled with the single VRT High Speed Spindle and a 90-degree head, is capable of machining on any side of the part — or even on the inside of parts, according to Bryan. The company currently has customers using this configuration to machine small parts for aerospace.

Bryan Machine Service can now double its production of small parts — even when the lights are out. Photo Credit: Bryan Machine Service.

Bryan says he already has a few companies interested in the twin-spindle design, and he believes any shop that runs small parts would benefit from using it. The shop plans to begin taking orders and running production once the design is patented. As Bryan says, “We’ve got to get through that initial process, and then we can get things rolling.”

Related Content

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreRead Next

Milling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=970;quality=90)