Share

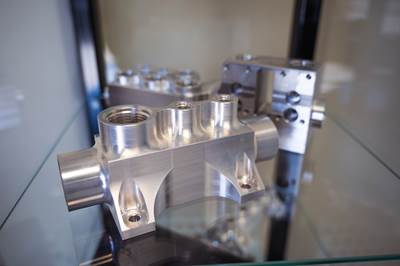

James Marzilli started his shop in 2011 on a dare from his wife Lee Anne Marzilli. In the years since, they have built the shop into a component and prototype manufacturer for high-end clients in the aerospace, medical and defense industries. All images courtesy of Lynn Gorman Communications.

“You don’t know how much waste you have until you address it,” says James Marzilli, founder and president of Marzilli Machine, a high-end component manufacturer located in Fall River, Massachusetts.

Marzilli has been running his shop since 2011, but even after adopting a simple ERP system in 2013, managing the shop and ensuring its efficient operation was a grueling task. “When I looked at shops that were one- or two- or four-man shops, the guy that ran that place was always broke, stressed out. He owned the business, but it almost looked like the business owned him. I felt that way as well at the very beginning of this.”

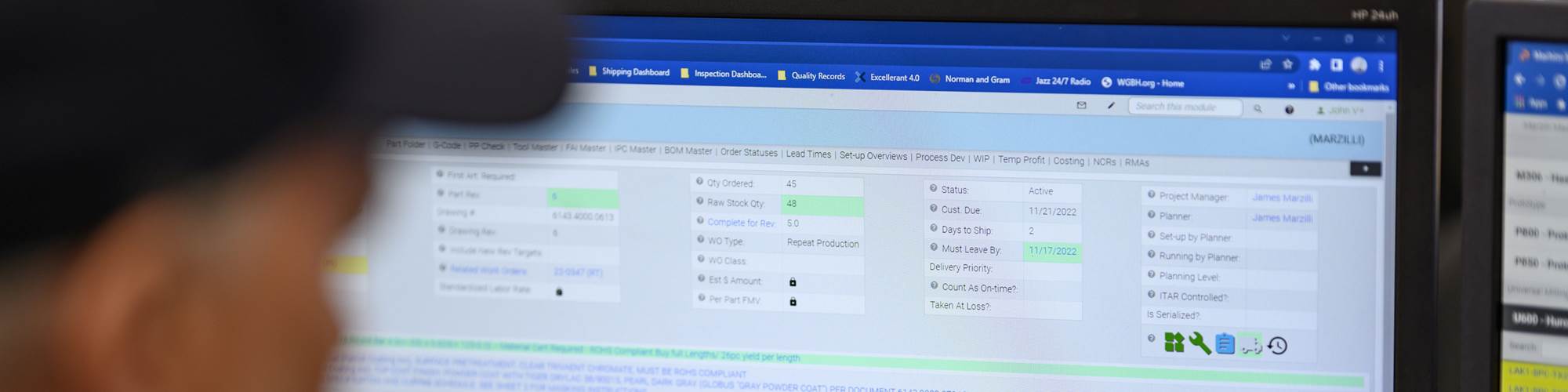

When COVID-19 shut down his home state, Marzilli decided to take stock of the business and how he wished to proceed. During this time, he read an advertisement for ProShop within Modern Machine Shop and decided to investigate further. This swiftly led to a test run with the software, which then led to officially adopting it within six months. Over the next year, the shop implemented process changes based on what it learned from the software, a task that increased Marzilli Machine’s gross revenue by 64% and lets James Marzilli take a deep breath while away from the shop.

Building a Better Process

The most obvious benefits of ProShop for Marzilli manifested as efficiency increases, reducing waste. This was especially apparent in the shop’s tooling management. Before 2020, the shop used what it thought was a traditional method: small to large, imperial to metric. Tools added during the year would have a temporary space until a yearly reorganization process.

ProShop has enabled the shop to digitally search for tools, with the results showing the exact drawer where setup personnel can find the correct tool. Marzilli can now ignore its previous organization methods, with search refinement reducing the time needed to find tools down to seconds.

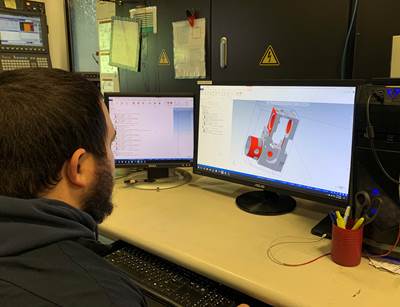

What’s more, the shop has developed a workflow linking ProShop Tool Manager with Mastercam Tool Library. Under this workflow, the shop digitizes its tools and imports them to the ProShop library, then imports that library into Mastercam. There is coding work to ensure the postprocessors function correctly, but when everything is complete, programmers can specify exact tools from the shop’s tool library and import the G code from Mastercam into ProShop to automatically populate the setup sheet with the exact tools necessary for the job. This blurs the lines between programmers and planners — deliberately, according to James Marzilli, who says that cross-training for the two roles has streamlined the programming process.

James Marzilli also calls out two ProShop features as catalysts for efficiency increases: Process Development and Shift Tie-In. Process Development enables operators to attach process suggestions to the part’s file in ProShop. When the shop gets a repeat order for that job — whether it be six weeks or six months later — that suggested refinement will be top of mind for management, who can then revise to improve the part setup. Shift Tie-In is for more day-to-day use, with James Marzilli calling it the digital equivalent of a sticky note. This feature facilitates communication between employees on different shifts, who can discuss tool wear, maintenance and other ongoing concerns for any given work order. If necessary, users can also turn these notes into Process Development suggestions at the press of a button.

ProShop enables Marzilli Machine to save different production plans to the same part number, enabling it to shift parts between machines when necessary.

Flexibility in Motion

These sorts of features streamline production and process improvement, while providing additional visibility into the production process. This visibility has better equipped the shop to plan out its production schedule.

For example, analysis of spindle hours and downtime helped Marzilli identify periods when operators could step away from a running machine to setup future jobs. By doing so, the shop reduced spindle downtime by 50%, freeing up capacity for additional work.

ProShop’s file system also enables multiple production plans to be stored under a single part listing, so if one machine is busy, the shop can quickly transition production of a part to an open machine on the floor. This pairs well with the shop’s machine-monitoring software, with the shop able to float employees between departments to target unexpected production needs and problems as they occur.

The Quality Control War Room

Marzilli attempts to minimize the frequency of these unexpected problems through what it calls its “War Room.” These are meetings between James Marzilli, the operations manager and the quality control manager in which the three theorize what could go wrong on a job and develop steps to prevent and mitigate failure.

“Everybody already understands how that job is going to go right — that’s the easy part,” James Marzilli says. Figuring out if a job needs a particular work accessory, or if a programmer needs to be reassigned to develop a custom CMM program before any problems actually occur is a relatively new habit for the shop, which only began holding these meetings after the initial introduction of ProShop. The idea that his job shop could be rife with inefficiency shook Marzilli, and he swiftly began seeking areas of improvement across the shop.

Until that time, the shop had only used High QA to balloon prints and generate hand-filled reports. Marzilli quickly began importing the quality data from the software into ProShop, a change which improved the shop’s ability to consistently meet high quality standards. This increase in quality capabilities swiftly led to an increase in clients looking for high-requirement parts. To ensure it could continue meeting the needs of these clients, the company started reviewing any jobs that resulted in errors and got into the habit of doing a lot more planning and prep work before cutting parts — planning and prep work that became the War Room meetings.

These meetings involve quality control from the beginning of a job, even before the company confirms delivery times to customers. The department confirms how many first and last articles each job needs, how many full inspections it requires and how it should run in-process checks, removing uncertainty from the job for a more consistent process. These decisions are now recorded in High QA alongside common causes of errors. James Marzilli says this takes quality decisions and practical knowledge from being “handshake agreements” to something everyone in the shop can easily check.

This emphasis on quality has also led to Marzilli using ProShop to schedule quality control checks on materials as they arrive. This catches incorrect material properties and mislabeled dimensions, saving hours of labor and eliminating the need for expensive emergency material deliveries.

Marzilli has filled its current 4,500-square-foot facility with three-, four- and five-axis mills, as well as CNC lathes. The company will move into a much larger facility in early 2024, where it will have space to purchase robots and other new capital equipment.

A Rapid Turnaround

Embracing these software resources and implementing the subsequent management changes have led to significant results for Marzilli. In 2021, the shop saw a 64% revenue growth without any capital spending. In 2022, the shop achieved 28% revenue growth without much more capital spending. Marzilli believed he would also break even in 2023, in contrast to many of the shop’s peers, who lost money due to a contraction in demand.

Part of the reason for the shop’s lack of capital investment has been lack of space in its 4,500-square-foot home, but Marzilli is in the process of moving to a space three times as large in early 2024. Marzilli plans to use part of this space as a rapid response center able to turn around emergency orders in less than a day, but much of it will enable the shop to begin investing in robots for full lights-out automation, expanding its capacity for what James Marzilli believes will be another wave of demand.

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreRead Next

Shop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

Read MoreBecoming a More Efficient Shop With the Right Processes and Software

After refining its machining processes for more efficient production, this shop still needed a better way to track its data. Here's how it found a software solution.

Read MoreDigitalized Job Shop Scales Up

New software sparks new thinking about meeting quality certification requirements without stifling growth.

Read More

.jpg;maxWidth=300;quality=90)