3 Reasons Machine Shops are Paying Attention to ERP

Awareness of people and the value of their efforts accounts for part of the reason why we are seeing enterprise resource planning being taken more seriously.

Many of the conclusions I come to as a witness to what is happening in manufacturing are anecdotal: impressions based on patterns I notice in what shop owners are saying or seem to be giving their attention to. The following conclusion is an example of that. It seems to me that 2020 has been — among many other things — a year for ERP.

That is, “enterprise resource planning” systems — software that organizes the different operations of a manufacturing company so that these operations can (in theory) work smoothly together rather than suffer from delay or duplication resulting from poor coordination between departments. This year, I have been noticing more questions from shops about ERP (“What systems are others using?” “What is working?”) and I have noticed shop owners more often citing their ERP system and/or their increased reliance on it as a bragging point in talking about their shop.

What could account for heightened interest in ERP?

Articles we have recently posted offer clues. A theme we have been developing in recent articles is “software and people.” Modern Machine Shop covers software all the time, but the core focus of machine shops’ software investments has always been the machines. CAD/CAM is a shop’s main software tool — that is, software for toolpaths, software for realizing the promise of the machine capabilities. Getting this part of the process right is vital. But what we are seeing now is a different sphere of software rising in prominence: software for realizing the promise of people’s capabilities.

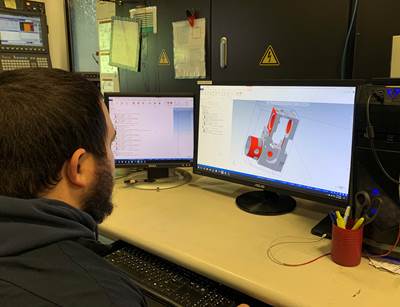

One of our recent articles on software and people describes the experience of Marzilli Machine. From the article: “One lesson of this Boston area manufacturer’s recent, rapid growth is that mismanaged inventory, lack of standardization, documentation errors and other systematic inefficiencies that do not always show up on a balance sheet can have as much impact as anything happening on the machine tools.” Read more. Photo courtesy Marzilli Machine Co.

For example, Marzilli Machine has seen the value of this. The Boston-area shop now views automation of communication and coordination as having a value on par with automating actions like machine loading. Indeed, I mentioned toolpaths, but what about “machinist paths”— conserving the attention and motion of skilled team members? Strikingly, ERP is also an enabler to the personnel-related challenge that is most characteristic of 2020: working remotely. And to make clear this idea is bigger than ERP, consider how the interface for flexible automation is also an important software tool for aiding people.

But back to the question of ERP. What could account for heightened attention to it this year? I see three likely explanations, perhaps more:

1. Acquisition brings systemization in its wake. Acquisition of machine shops is happening – I wrote about my observation of this. Shops are being bought by other companies, often to be merged into larger manufacturing organizations. When this happens, the context that needs to give way is the shop’s tribal knowledge — meaning the practices that proceed by the unspoken assumptions everyone “knows.” Of course, the new owner does not “know,” and the unspoken system probably buries inefficiencies no one thinks about. ERP implementation, or the shift to greater reliance on ERP, is a natural means to a more transparent process.

2. Slowdowns free attention for disruption. Shops have varied this year in their activity levels, but for some, business has softened. The quieter time can bring opportunity. Having some attention free, and having margin in terms of the availability of people’s time and equipment capacity, provides the chance to make messy changes. And commitment to ERP is a change that is inherently messy, because it involves changing individual work habits that have come to feel comfortable. Indeed, ERP is a special kind of investment. A shop will buy a new machine tool if it is very busy, but the shop practically requires a lull to be able to put ERP to work.

3. Hiring is not getting any easier. I recently had a need to pull out an issue of Modern Machine Shop from 20 years ago. Flipping through it, I realized that the seeming shortage of skilled employees is something we were writing about just as fervently way back then. This problem will not go away, and the special uncertainty of 2020 only complicates the matter. A shop now is liable to be reluctant to staff up even if could easily do so. The tools within a good ERP system, perhaps the very system the shop has been underusing all this time, provide the means of holding staff constant but allow each staff member’s time and attention to be used more effectively.

Still, ERP going underused has long been a phenomenon. What might be changing now, in 2020? Maybe there is a fourth explanation in addition to the three above, an explanation found in the insights of this unsettled year. Once I finish writing this piece, I need to check in with a colleague via a video call in Teams, a means of communicating I never employed before this year. Working in the time of COVID-19has reminded us of the value of people, and it has taught us we have useful digital tools for connecting and collaborating that were just waiting for us to need them.

Related Content

Becoming a More Efficient Shop With the Right Processes and Software

After refining its machining processes for more efficient production, this shop still needed a better way to track its data. Here's how it found a software solution.

Read MoreAutomation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

Read MoreData Visibility Boosts Beryllium Shop’s Revenue

Consistency is key for beryllium manufacturing, so the data visibility granted by Harmoni has swiftly become a vital, profitable tool in the shop’s arsenal.

Read MoreIncrease Savings and Streamline Purchasing Operations with Amazon Business

Machine shops and small manufacturers are finding cost and time savings using Amazon Business in their shops.

Read MoreRead Next

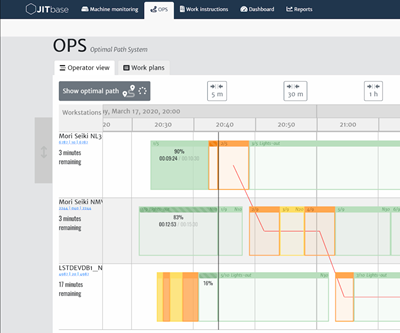

Mapping the Optimal Path for Machinists

Using data from machine monitoring systems and CNC programs, OPS calculates the most efficient path for operators to take across the shop floor, improving uptime and increasing machines per operator.

Read MoreDigitalized Job Shop Scales Up

New software sparks new thinking about meeting quality certification requirements without stifling growth.

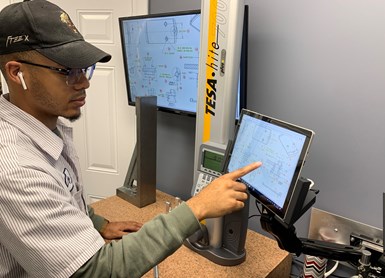

Read MoreVerisurf Companion App Offers DRO, Remote Control Functions

Verisurf Software now offers a companion app to its metrology software designed to improve productivity, especially when large parts or assemblies are involved.

Read More

.jpg;maxWidth=300;quality=90)