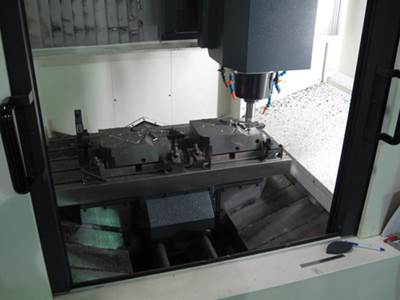

Vertical Machining Centers

The Promise of "High Cube" Machining

Tool paths and a new tool design provide an alternative to high speed machining for achieving high metal removal rates in hard metals on lighter-duty machines.

Read MoreVideo: Milling Inconel 718 Efficiently Without a Heavy Machine

This video of machining Inconel at a fast metal removal rate shows the effect of constant-engagement-angle milling.

WatchVideo: Milling Titanium 6-4 Efficiently Without a Heavy Machine

This video of machining titanium at a fast metal removal rate shows the effect of constant-engagement-angle milling.

WatchBridge, Gantry And Traveling-Column Machining Centers

Republic Lagun Machine’s manual and CNC milling machines, lathes and CNC machining centers are suited for power generation; aerospace; renewable energy; iron and steel; railway; earth moving; oil and gas; construction; and defense industries. Republic’s Spanish partner, Maher Holding Group, offers Zayer machines, among others.

Read MoreWhen to Mill Keeps Changing

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

Read MoreMachine Line Alleviates Workflow Bottlenecks

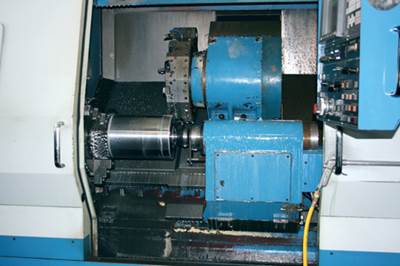

Workflow bottlenecks led this oil and gas industry manufacturer to seek a new line of machine tools. Standardizing on mills, lathes and other machines from FEMCO eliminated operator training issues while reducing process time and tooling costs.

Read MoreVMCs For Speed, Economy

Doosan’s DNM VMCs are available in three sizes: the DNM 400 with a 36. 2" × 17.

Read MoreThree-Meter Machining Center

Hurco says its largest machining center, the 3-m DCX32, has the capacity to handle large parts and molds for the aerospace and energy sectors. Featuring X-, Y- and Z-axis travels of 126" × 82.

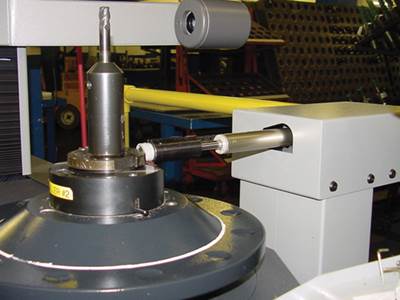

Read MoreTool Certainty

For GKN Aerospace to overcome tool-related variations on its largest milling machines, it had to confront error sources that go unnoticed in many shops.

Read MoreAluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

Watch

.jpg;maxWidth=300;quality=90)