Aluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

Share

A veteran mold builder with Phoenix Proto Technologies explains design differences between an aluminum mold for prototypes and an aluminum mold for production.

Phoenix Proto Technologies (www.phoenixproto.com) opened shop a year and a half ago with the goal of quickly producing aluminum molds for customers in need of prototypes. Noting continued use of aluminum bridge tooling and a growing interest in aluminum molds for production applications (thanks in part to better alloys and shorter product design cycles), it has since gone after work for all three of these moldmaking scenarios. That said, its approach for creating all types of aluminum molds is the same as is its guaranteed delivery time of three weeks or less.

Robert Lammon is the director of sales for the Centreville, Michigan company. From the beginning, Mr. Lammon explains, PPT looked to compress the time spent on all aspects of the mold building process, from quotation to machining to plastic part production. He says what supports this strategy on the machining side is standardization of key mold components and equipment that offers both high speed machining and reliable, lights-out production. During a recent visit, he explained how the 15-person shop wrings wasted time out of the various phases of the aluminum moldmaking process.

Instant Prototyping Process

PPT calls its moldmaking approach Instant Prototype Processing. Its goal is to create aluminum molds without limiting a customer’s design, and it guarantees the aforementioned fast tooling turnaround for parts as large as 12 by 12 by 4 inches. In addition to its five CNC machining centers, the company has five Niigata injection molding machines ranging from 85 to 330 tons for customers wanting it to produce plastic part samples in addition to the aluminum tooling.

Most of the company’s work comes from the medical and consumer products markets. Quotes for each new job are provided to the customer in less than one hour after receiving an RFQ. As soon as the company receives a purchase order, programmers and toolmakers gather to discuss mold design specifics such as parting line, gate and vent locations. Within 24 hours of receiving that purchase order, it conducts a design review with the customer (often via the GoToMeeting Web conferencing application) and then finalizes the new job internally with a pre-tool meeting. A recently integrated computer server system makes file sharing between all parties a simple drag-and-drop process, greatly speeding and simplifying file transfers that were previously carried out via e-mail.

PPT’s CAM programmers, who are also mold designers, next start determining how best to machine core and cavity features, either via EDM or milling. The company stocks standard-sized core/cavity inserts as well as universal mold bases. That way, it can immediately schedule and set up insert machining jobs as soon as programming is completed.

The VMC used for 80 percent of the company’s milling work is a Mikron HSM 600, available from GF AgieCharmilles (Lincolnshire, Illinois). PPT chose this machine for two primary reasons. First, its 42,000-rpm spindle provides the speed to quickly cut through both the 7075 aluminum the shop typically uses (sometimes in hardened condition) and graphite electrodes for its ram EDM. The Mikron machine is fitted with a dust evacuation system to remove particles generated during graphite machining. However, the company chooses milling over EDM whenever possible to eliminate the requisite electrode milling step prior to burning.

The second reason the shop settled on the high speed machine was because it offered a compact, integral pallet changer. This enables setups to be performed on multiple pallets outside the machine’s work environment while the machine is running another job. This also allows lights-out production, which minimizes spindle downtime and eliminates the need to staff three shifts. PPT commonly installs multiple vises on each pallet, and it has also created a fixture that can hold numerous electrodes to maximize the number of jobs the VMC can complete without operator intervention.

Many milling operations on the high speed machine call for small-diameter tools. Although uncommon, tool breakage is possible when cutting aluminum. To prevent overnight air cutting resulting from a broken tool, machine programmers commonly call for more frequent-than-usual tool changes even though a tool’s effective life hasn’t been approached.

Prototype Molds Drive New Machine Purchase

The aluminum molds PPT creates for prototype and production applications differ in the way undercuts and other part features are executed inside the molds. In nearly all cases, prototype molds use hand-loads to create these features rather than the mechanical slides common to production molds. Hand-loads are machined components that are manually inserted into the ejector side of a mold before each shot. Once the shot is completed, the hand-loads eject with the molded plastic part. An operator removes the hand-loads from the part and reinstalls them into the mold for the next shot.

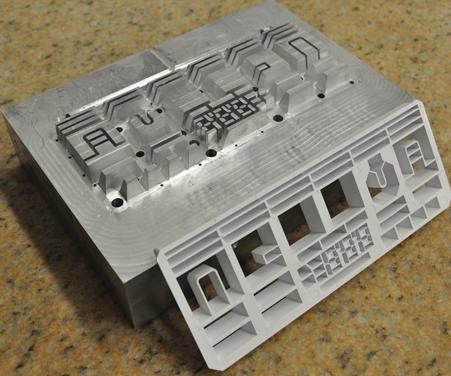

This manual intervention is justified because prototype lot sizes are very low. Plus, molds using hand-loads can be designed faster and cost less than those using mechanical or hydraulic actions. A selection of hand-loads is shown in a photo to the right. That prototype mold creates an ignition switch that requires 15 undercuts.

PPT recently purchased a Captain five-axis lathe from Okuma (Charlotte, North Carolina) with the goal of machining hand-loads and other small mold components in one setup. This will free the Mikron VMC to mill predominantly electrodes and core/cavity inserts. The lathe is well-suited to complete such components that may have tapers and drafts from both rectangular and round stock.

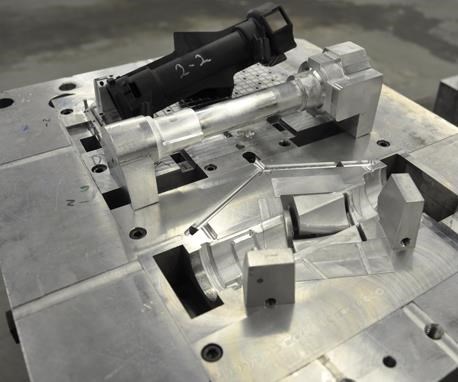

The other mold image on the right is a production mold that PPT created to produce a cover from unfilled nylon. This particular aluminum mold uses some mild steel components such as gibs and bottom plates. However, PPT routinely manufactures molds made entirely of aluminum components. In these cases, aluminum components that slide against each other will be hard-coated for improved wear resistance and tool longevity.

Mr. Lammon believes demand for aluminum molds for prototyping applications will remain strong. He’s quick to point out, though, that an increasing number of large manufacturers are beginning to realize that compared to steel, aluminum molds can be created quicker, cost less and enable faster injection molding cycle times due to better thermal characteristics.

It’s not uncommon for today’s aluminum molds to deliver 1 million shots, Mr. Lammon says, which might be sufficient to satisfy the production requirements for a company that continually updates its products or introduces new ones. He’s betting that this will lead to additional work for PPT as these companies realize the benefits aluminum molds offer for both prototypes and production.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreTop Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)