Machine Line Alleviates Workflow Bottlenecks

Workflow bottlenecks led this oil and gas industry manufacturer to seek a new line of machine tools. Standardizing on mills, lathes and other machines from FEMCO eliminated operator training issues while reducing process time and tooling costs.

Share

When Houston Oilfield Equipment brought its first FEMCO CNC lathe online in 2001, few would’ve guessed it would be the first in a long line of machines purchased from the Garden Grove, California-based supplier. By that point, the company had tried three different machine tool brands, none of which provided the mix of quality, ease of use, responsive service and affordability needed to meet delivery times and keep product pricing competitive. Standardizing on the FEMCO line eliminated workflow bottlenecks while reducing cycle time and tooling costs.

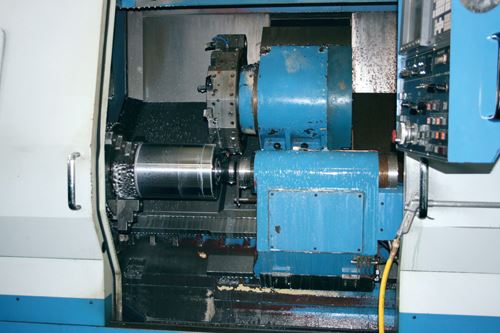

Houston Oilfield Equipment was founded in 1993 in Houston, Texas, an oil and gas industry hub from which the company could serve both domestic and international markets. Its main product is a choke valve created by owner/president Tom Bowers that is used in oil and natural gas drilling. The company’s 16 employees rely on a number of machines from FEMCO, including six CNC lathes, one CNC mill, one manual mill, two automatic saws and a hydraulic drill press. The majority of the material the company machines is steel, including carbon steels and varieties such as 4130, 4140, 410SS and 17-4 PH SS.

The CNC lathes and the CNC mill are used for large production runs. The CNC lathes, which are capable of heavy stock removal, finish machining, ID/OD threading, boring, machining tapers and angles, and more, play a part in machining all component parts of the product line. Meanwhile, the CNC mill produces ring joints on flanges and threads as well as keyway slots and angular details on part IDs and ODs. The manual mill and lathe are used for low-volume jobs, with the mill performing similar operations as its CNC counterpart and the lathe—the shop’s least-active piece of equipment—repairing or machining single parts. The automatic saws cut solid bar and tubing into pieces prior to machining. Finally, the hydraulic drill press performs boring operations, clean-up operations after welding choke body flanges, and machining of autoclave HP thread ports and 1/2" NPT ports.

The shop moved to the FEMCO line in response to rising customer demand. As business increased, Mr. Bowers and shop foreman Beto Zamarripa noticed significant bottlenecks that threatened to cause overlapping and delay in delivery times. To remain competitive, the shop needed to expand its CNC machining capacity and address problems with training new machinists. Employee difficulties with operating the shop’s previous machines led Mr. Zamarripa to spend a great deal of time dealing with that issue at the expense of other important duties.

Searching for answers, Mr. Bowers met with FEMCO’s Southern Texas distributor, Scott Murray. Mr. Murray convinced Mr. Bowers that the company could provide what the shop was looking for—a professional relationship that provided a reliable source of support and knowledge. The machines themselves also seemed promising, with features including spindle bearings that can safely support heavy loads and an open configuration that eases access to machine internals as well as part loading and unloading. “Once we standardized on the line, our problems seemed to disappear,” Mr. Bowers says. “The machines are easy to operate and maintain, and their Fanuc controls are easy to understand.”

Mark Kindell, the plant superintendent, adds that any operator can run any given machine and not encounter any problems, such as the turret issues the shop experienced with some of the other machines it had used previously. Tool costs have also decreased because the same tooling can be used throughout the shop, as opposed to putting in special orders for different toolholders used on different machines. Perhaps most significantly, the shop’s process time has improved by an average of about 20 percent since standardizing on the FEMCO line.

One recent job involving the processing of flanges that form part of the inlet and outlet connections of chokes provides an example. These involve OD turning, ID boring, machining of ring grooves and drilling of bolt holes. With the company’s previous CNC machines, this job required approximately 2 hours of process time. That process time has been reduced to 1 1/2 hours using the new machine line. “We have had very little downtime with FEMCO compared to other brands, and their service technicians are very responsive to our needs,” Mr. Bowers concludes. “We will most definitely purchase more machines as our business warrants.”

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)