Vertical Machining Centers

VMCs Designed for Performance and Value

Methods Machine Tools is the exclusive N.A. importer of Fair Friend Group’s range of Feeler machines, which are designed for performance and value.

Read MoreHow is Large-Part Machining Different?

A shop serving the wind-power industry illustrates some of the challenges particular to machining massive workpieces.

Read MoreComposites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

Read MoreAdvanced CNC Milling and Drilling Quiz

A provider of machine shop training offers these questions for benchmarking metalworking knowledge.

Read MoreHard Milling Reduces Lead Time, Manual Labor

Investing in a hard milling machine from Makino has enabled this fineblanking manufacturer to reduce lead time by 55 percent, reduce manual labor and improve part quality.

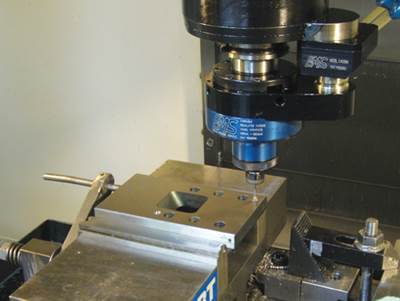

Read MoreMilling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

WatchMini VMC Line Available in Three Models

Sharp’s Mini Mill series of VMCs features a 6 sq. ft. footprint and is fully enclosed.

Read MoreVMC for Die/Mold and Medical Markets

Makino’s F series VMCs are designed to provide stiffness and rigidity for chatter-free cutting; agility for high-speed/hard-milling; and accuracy for tight tolerance blends and matches typical of complex, 3D contoured geometry associated with die/mold and medical production.

Read MoreNew Generation of VMCs

Haas’ redesigned VF product line incorporates enhancements to motion control, coolant containment, chip evacuation, ergonomics and serviceability.

Read More

.jpg;maxWidth=300;quality=90)