Tooling

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreChipbreaker Improves PCD Productivity in Non-Ferrous Jobs

Tungaloy’s NS chipbreaker improves its PCD inserts’ chip management, reducing machine downtime and improving surface finish on non-ferrous materials.

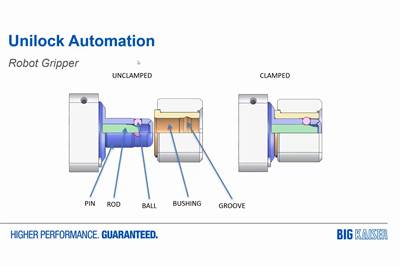

Read MorePutting Production on Repeat with Machine Tool Automation

Cobots and automation advances have spurred tooling and workholding innovations like Big Daishowa’s zero-point workholding system and EWA fine boring head.

Read MoreIndexable Milling Cutters for Semi-Finishing of 3D Surfaces

Tungaloy’s AddForceBarrel is said to provide greater engagement area between the cutting edge and workpiece compared to conventional ballnose end mills.

Read MoreCarbide Drill Designed to Deliver Coolant Closer to Cutting Edge

Walter’s DC 175 Supreme solid carbide drill is designed for increased performance in stainless steel and superalloy machining.

Read MoreCeratizit Offers Inserts Optimized for Steel Turning

Three new, standard, coated-carbide, ISO-P steel inserts from Ceratizit are each optimized for specific production conditions.

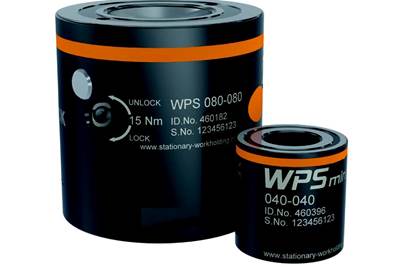

Read MoreMini Workpiece Positioning System Offers Fast, Flexible Setup

SMW Autoblok’s 40-mm Workpiece Positioning System (WPS) Mini is designed to reduce setup times and offer flexibility, especially for small workpieces that require quick part changeover.

Read MoreWorkholding 101

No universal workholding solution exists, so machine shop employees should have a basic understanding of multiple ways they can secure workpieces.

Read MoreMikron Adds Toric Version to Milling Cutter Family

Its CrazyMill Cool P&S milling cutter family expands to include Typ A and Typ C, which feature optimized geometry and integrated cooling channels.

Read MoreMulti-Directional Turning With New Turning Concept

Tungaloy’s AddMultiTurn provides the flexibility for outer diameter, face and profile turning operations in multi directions, which include high-feed back (pull) turning method, enabling toolpaths that turn in the opposite direction of conventional turning process at higher feeds.

Read More