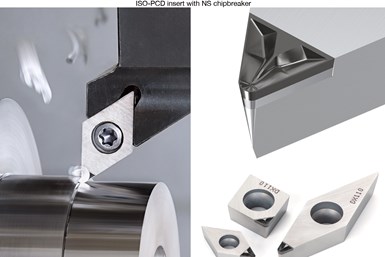

Chipbreaker Improves PCD Productivity in Non-Ferrous Jobs

Tungaloy’s NS chipbreaker improves its PCD inserts’ chip management, reducing machine downtime and improving surface finish on non-ferrous materials.

Share

Photo courtesy of Tungaloy America, Inc.

Tungaloy has launched ten new PCD inserts with its three-dimensional NS chipbreaker. The company says the DX110 grade of these inserts improves their edge line, enabling higher-quality surface finishes.

These inserts break up the long continuous chips that can form during machining of gummy, non-ferrous materials such aluminum or copper alloys. Breaking the chips reduces machine downtime due to chip-associated troubles, while also eliminating surface finish-lowering chip scratches on machined surfaces.

The NS chipbreaker is directly engraved on the PCD tip, and caters to cutting depths up to 2.0 mm (0.079 inch). Tungaloy says PCD inserts with this chipbreaker can both rough and finish, allowing users to reduce insert inventory and better integrate machining processes.

Related Content

-

OSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

-

Walter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.