Tooling

Parlec Launches Coated ER Collet System

Parlec’s P3 ER collets feature an anti-friction coating on the 30° face of the collet that interfaces with the collet nut when tightening during tool setup. Parlec says the collets can be used in any ER collet chuck to improve accuracy and cutting performance.

Read MoreHigh-Performance Chip Splitter Maximizes Metal Removal Rate

Hanita’s VariMill Chip Splitter is said to deliver higher metal removal rate (MRR) by separating long, undesirable, stringy chips from deep cavities and dynamic milling paths by cutting material into shorter, more manageable sections.

Read MorePalmgren Delivers Powerful Precision Drill Press

The 25" Power Feed Gear Head Drill Press’ gear drive transmission reportedly delivers full power at any speed, driving the cutting tools at nearly 100% of the available motor horsepower.

Read MoreWalter Introduces New Milling Grade That Finishes With One Cutting Edge

Walter’s new WHH15X milling grade can reportedly provide extra-long tool life, especially with hardness of 58 HRC or greater. The new grade can be used universally for finishing on ISO materials P, K and H, and is said to be ideal for copy milling in die and mold making.

Read MoreFull-Grip Chuck Jaws Hold Delicate Workpieces Without Marring

Dillon Manufacturing says its full-grip chuck jaws are ideal for high-speed machining, as well as precision boring, tapping, drilling and finishing across virtually all industrial markets. Brass provides a softer surface without marring or marking of the workpiece surface.

WatchKurt Manufacturing Introduces Compact Vise

The 8" DX8 CrossOver vise features a redesigned nut with less weight, a new brush seal design and a larger, stronger bearing pack for more durability.

Read MoreSMW Autoblok Acquires Tecnomagnete

Tecnomagnete is said to have invented the use of permanent magnetic systems for component clamping, plastic injection molding, stamping and lifting.

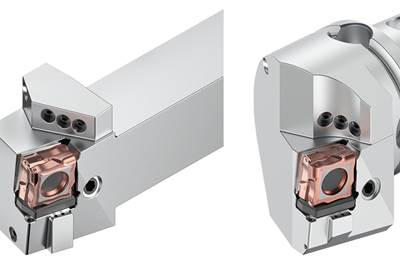

Read MoreNew Kennametal Turning System Has Eight Cutting Edges Per Insert

Kennametal’s Fix8 turning system is said to increase productivity of heavy-duty turning operations while providing the lowest cost per edge and reducing cutting forces up to 15%.

Read MoreHigh-Pressure Coolant System Reduces Cycle Time More Than 6 Hours

A suite of systems from LNS has enabled Velco Tool & Die to reduce cycle times and increase its throughput.

Read More3D Printing Lightweights Large Cutting Tools

Larger parts require larger, heavier cutting tools. 3D printing enables Star SU Neher to produce lightweight large tool bodies and add features that improve tool life and performance.

Read More