Tooling

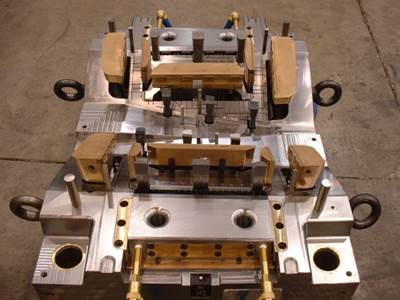

Cutting To The Model

This mold shop's cutting tool strategies help it eliminate hand spotting altogether by machining complex molds directly to the CAD model.

Read MoreMilling Adaptor: Reach Without Reluctance

An alternative to conventional extended-reach toolholders, milling adaptors contain a custom damping mechanism to minimize vibration when milling long overhangs.

Read MoreRealizing Large-Scale Savings On Large-Scale Parts

Converting big square bars to largely round tie bars used to require 24 hours per piece at Oak Products. The Sturgis, Michigan, company can now complete the same job in 8 hours. How did the company slash its machining times and realize substantial cost savings? Oak attributes the turnaround to process re-engineering involving aggressive mill-turning and tooling geared to stand up to the challenge.

Read MoreGear Manufacturer Gains Efficiency With Tool Management System

When producing a large number of complex, high-value-added parts, processes are continually examined and optimized, and this influences the style and numbers of cutting tools that are used each day. Avon Gear Company (Rochester Hills, Michigan) knows this first-hand.

Read MoreThe Case For Quick Change On Multi-Spindles

Even in the world of long-running, high-volume production on cam-driven automatics, quick-change tooling makes sense.

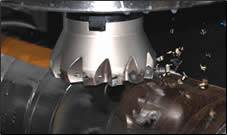

Read MoreHard Milling With Tandem Toolholding

A combination of toolholding choices lets this die shop get the most performance from its small-diameter tools.

Read More