Tooling

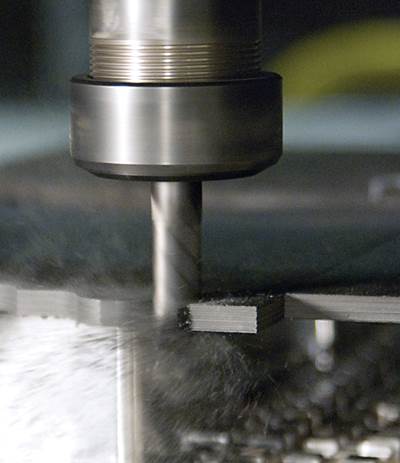

Expanded End Mill Line

Primary Cutter’s expanded Supermill-XP end mill line is available in chamfer, corner- radius and sharp-corner styles, as well as in regular, stub, long and extra-long lengths. The variable-pitch end mills feature a four-flute design and a 45-degree helix angle.

Read MoreVariable-Design End Mills

OSG’s Exocarb Aero UVX variable index and variable helix end mills couple positive edge geometry with a variable helix design. The end mills can achieve more consistent, chatter-free milling versus common variable-design end mills, the company says.

Read MoreCutters Compress To Effectively Machine Composites

The combined up-cut and down-cut spiral flutes on these cutters compress layered composites to prevent delamination during machining.

Read MoreDrill Sharpener Helps Shop Hone Competitive Edge

Bringing drill sharpening operations in-house saved both time and money at this Chicago-based manufacturer. However, the sharpener itself, Darex’s XPS-16, provided additional benefits—with high accuracy and consistent results, the machine helped the company maintain precision and quality.

Read MoreCYCLO CUT HSK63A End Mills

(Sponsored Content) CYCLO CUT cutting tools offer integral shank HSK63A end mills for use in high speed machining of large aluminum structural components. Integral design allows indexable cutting while running at high RPM’s, and much higher cutting capabilities. Cutters are available up to 2.00” in diameter with reaches of 2.00” to 4.00”.

Read MoreCoolant-Through Carbide Drills

OSG’s coolant-through carbide drills are available with WD1 coating, which inhibits the wear on the shoulders and margin, or TiAlN coating. Two flute lengths are available: Exocarb-FTO 5D and Exocarb-FTO 3D.

Read MoreCustom Tool Storage System Simplifies Setups

Investing in a presetter and additional toolholders helped this manufacturer of custom industrial machinery eliminate mistakes during the tool setup and offsetting process. However, taking full advantage of these investments required a custom, in-house-designed tool storage system that enables efficient management and storage of the shop’s large array of cutting tools.

Read MoreDoes Small-Hole Drilling Demand a Fast Spindle?

A reader with a 10,000-rpm drill press can drill a 0.019-inch hole in stainless, as long as all the contributors to runout are controlled.

Read MoreTriple Tap Life

A maker of vehicle components finds that a treatment process for taps produces dramatically longer tool life.

Read MoreGrades For Grooving and Parting-Off

Seco Tools has added its Duratomic process technology to two cutting grades designed for grooving and parting-off applications. During the Duratomic process, aluminum oxide is arranged at the atomic level to adjust the coating to fit specific applications and workpieces.

Read More

.jpg;maxWidth=300;quality=90)