Tooling

How Do You Get The Cutting Parameters Right For Small End Mills?

A reader recently asked about speed, feed rate and depth of cut when using small tools in steel.

Read MoreInserts Cut Stainless And Super Alloys

SGE inserts for Kennametal’s Mill 1-14/18 platform are said to improve performance for companies machining stainless steels, super alloys and high-strength steels. Micro-geometry features, such as a 20-degree rake angle, a negative T-land and a small hone, enhance the inserts’ performance by increasing feed capability, reducing cycle times, lowering cutting forces and increasing tool life.

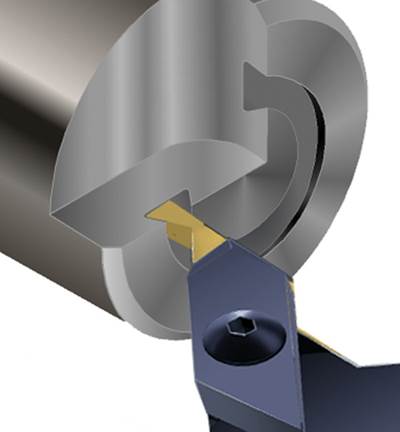

Read MoreInserts For Threading Applications

Sandvik Coromant says a new insert size for the CoroThread 266 allows the rigid tool to be used in a majority of general threading applications. The new size 16 inserts complement the existing sizes 22 and 27.

Read MoreButton-Style Mill For Heavy Roughing Operations

Valenite LLC introduces the V200, a heavy-duty, button-style mill for facing and profiling. The tool utilizes VP2003 round inserts with MicroForm carbide-grade technology, which enables inserts to be direct-pressed with a micrograin structure.

Read MoreDovetail Grooving Inserts

Thinbit, manufactured by Kaiser Tool Company, has expanded its Groove ‘N Turn line to include dovetail grooving inserts. Dovetail grooving inserts are used to machine O-ring dovetail grooves with 66-degree undercut angles.

Read MorePart-Off Gang Tooling

Arno-Rouse has incorporated existing cut-off support blades into a gang tooling concept. Designed for screw machines, the tooling features 0.

Read MoreGrades For General-Purpose, Interrupted Turning

The wear-resistant Super FF coating (Fine and Flat) on Sumitomo’s AC820P and AC830P grades is said to reduce the possibility of chip adhesion due to its smoothness. Combined with carbide substrates, the series is said to offer higher speed capabilities and greater resistance to breakage than conventional carbide grades when machining steels and stainless steels.

Read MoreChasco Turns On Success By Turning Out The Lights

Jeff Roth, president of Chasco Machine, knew he needed reliable equipment to successfully implement unattended operation. Bar feeders and a chip conveyor from LNS helped the shop make the most of its move to lights-out manufacturing.

Read MoreHydraulic Stationary Chuck

Hainbuch has extended its modular system to the company’s Hydrok stationary chuck. This hydraulically actuated stationary chuck is available in hexagon and round variants.

Read MoreCYCLO GRIP Milling Chuck

The new MAG CYCLO GRIP Milling Chuck grips end mills with 4,700 pounds of clamping force and .0004 runout. This tool holder is ideal for hard metal cutting using large diameter end mills. It can also be used to hold shank style tools including back-spotfacing tools.

Read More

.jpg;maxWidth=300;quality=90)