Tooling

Live Lathe Tools For ID Machining

Eltool’s live tool modules combined with the company’s right angle heads are designed for internal machining of bores ranging to l" in diameter. Secondary ID milling, drilling, slotting and grooving operations can be integrated into turning operations to increase throughput, reduce handling and improve accuracy.

Read MoreMilling Toolholders Reduce Vibrations

Although long-overhang tools can reach deep cavities and other difficult-to-access areas, such cutters can introduce vibration into the machining process. To address this issue, Seco Tools’ Steadyline vibration-damping shell mill holders feature a passive dynamic damping system that offers as much as 3× the rigidity of common solid holders.

Read MoreCoroCut Program Grooving Line Expands

Sandvik Coromant’s expanded CoroCut program features larger insert seat sizes for wider grooves and a dedicated grade to enable higher performance in demanding parting and grooving operations. The M- and R-size inserts and holders increase the range of the parting and grooving program to cover from 0.

Read MoreAngle Head For Makino HMCs

Koma Precision stocks Alberti Slimline T90sl-0,3 angle heads, which are customized for Makino MAG3 HMCs. The angle heads feature an HSK 80F shank and a high speed NSK output, which can be equipped with a variety of micro-machining NSK tools.

Read MoreSolid Carbide, Four-Flute End Mills

Iscar’s expanded Chatterfree line of solid carbide, four-flute end mills includes smaller diameter sizes of 0. 125", 0.

Read MoreDrill Program For Small Diameter Ranges

Mikron Tool’s drill program for small diameter ranges includes the MiquMill Frontchamfer. Available in diameters as small as 1 mm, the mini chamfer mill is designed to machine hard-to-reach spots.

Read MoreTool Certainty

For GKN Aerospace to overcome tool-related variations on its largest milling machines, it had to confront error sources that go unnoticed in many shops.

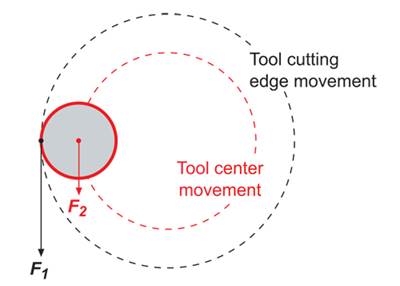

Read MoreGet The Feed Rate Right When Thread Milling

Does your machine control specify radial feed rate from the edge of a tool or its center? Not knowing can cause much longer cycle times or greatly reduced tool life during thread milling operations.

Read MoreDovetail Vise-Clamping Component

AME says its dovetail vise clamping component is useful for a variety of applications and industries, especially aerospace aluminum milling applications. Precision bushing holes are designed for quick and easy location of the vise, the company says.

Read MoreHexagonal Pole Magnets

A line of electro-permanent workholding magnets from SAV North America is designed to accommodate a range of material sizes and shapes for milling operations. HEX Pole milling magnets are said to deliver greater holding power per square inch with six-sided (hexagonal) pole configurations versus typical square-shaped magnets.

Read More

.jpg;maxWidth=300;quality=90)