Milling Tools

Mainstream Technology Keeps Shop On Track

In its toolroom, Branchline Trains takes a practical approach to machining with end mills as small as 0.005 inch in diameter.

Read MoreThe Real Cost Of Runout

A seemingly small amount of runout can still be too large for the tool. Reduce this runout, and tool life or productivity may dramatically increase.

Read MoreMachining’s Role In Making Cancer "History"

A machine shop in a new cancer treatment center produces components to precisely guide proton radiation to eliminate its target—cancerous tumors.

Read MoreA Two-Speed Approach To Plunge Roughing

In plunge roughing, the strategy is in the stepover. Here is a plunge roughing strategy that has worked well for Boeing researchers.

Read MoreThe Hard Milling Imperative

Hard milling allows mold components to be machined in the hardened state, thus skipping several expensive and time-consuming processes such as electrical discharge machining and hand polishing.

Read MoreTools For Titanium

With all of the titanium that will be required for a new aircraft, any of 1,000 spindles might benefit from the tools and techniques described here.

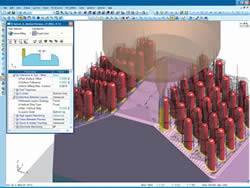

Read MoreCAD/CAM Considerations For Micromilling

Milling with tools that are smaller than 100 microns in diameter presents equipment design and toolpath-generation challenges. This NC software maker offers strategies for creating safe, optimized tool paths for micromilling.

Read More

.png;maxWidth=300;quality=90)