Milling Tools

Micromachining Evolution

Challenge Machine continues to add high-speed equipment for the increasing amount of micromachining work it is performing. Here are some lessons it has learned along the way, using tools as small as 0.001 inch in diameter.

Read MoreSolid Carbide End Mills Improve Chip Evacuation

Haimer’s Power Mill solid carbide end mills are made from fine-grain carbide and are equipped with the company’s Safe-Lock shank pull-out protection system.

Read MoreFour-in-One Cutting Tool System for Diverse Applications

Millstar’s Quad Force Machining systems of solid carbide cutting tools feature cutting geometry with the capacity to perform four cutting actions in one.

Read MoreCutting Platform Reduces Horsepower Draw

Widia’s Victory VSM11 platform includes cutter bodies and inserts designed for low-horsepower draw and free machining.

Read MoreISO 13399—A Key Step Toward Data-Driven Manufacturing

Decisions about the cutting tools used in machining operations are arguably among the most important in modern manufacturing.

Read MoreCutting Tool Edge Prep: The Invisible Advantage

Edge preparation involves removing material from a cutting tool in order to extend its life. That may sound counterintuitive, but a maker of glass molds says edge prep has dramatically reduced the amount it spends on tools.

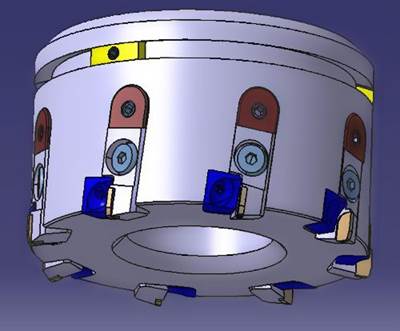

Read MoreCutters and Inserts Enable Continuous Heavy-Duty Cutting

Lovejoy Tool Co.’s MaxCut 651 cutters feature a new chip gullet design and 0.250"-thick inserts for continuous heavy-duty work.

Read MoreCutting Tool Helps Automotive Manufacturer Implement Design Change

Horn USA’s Mini Mill helped Machine Tool and Gear mill a flat at 90 degrees from other operations.

Read MoreFace Mills Keep Shop from Making Large Capital Expenditure

By retooling its machines with Tedimill face mills from Ingersoll Cutting Tools, Ward Production Engineering was able to take on a jump in order volume without making a large capital investment.

Read MoreThe Anatomy of an End Mill for Titanium

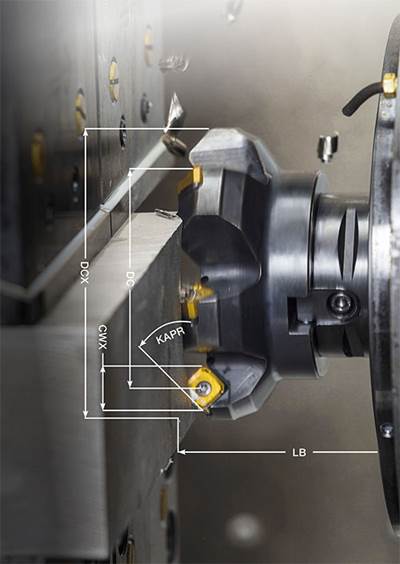

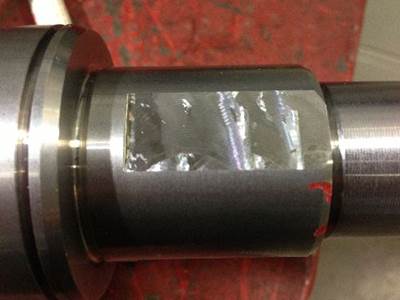

Titanium is often characterized as a “challenging workpiece material.” Certainly, machining this material is a challenge to milling machines, cutting tools and workholding accessories that are suitable for machining more common materials such as mild steel, cast iron or aluminum.

Read More

.png;maxWidth=300;quality=90)