ISO 13399—A Key Step Toward Data-Driven Manufacturing

Decisions about the cutting tools used in machining operations are arguably among the most important in modern manufacturing.

Share

Decisions about the cutting tools used in machining operations are arguably among the most important in modern manufacturing. ISO 13399, a set of international standards that enables cutting tool manufacturers to use the same “language” to describe their products in a digital format, makes it easier for cutting tool data to be transferred seamlessly across various software platforms. This data should lead to better decisions that will improve productivity and significantly cut costs. As a result, ISO 13399 is a major step toward data-driven manufacturing. For this reason, every company that uses machining processes in manufacturing should have a basic understanding of this important standard.

Of course, in addition to adopting ISO 13399, the manufacturing community must take other steps to complete the pathway to data-driven manufacturing. For example, factories and factory personnel must become fully networked. Other steps include promoting data-exchange standards such as MTConnect and completing work on a generic tool classification system that complements ISO 13399. Progress in these areas will accelerate implementation of data-driven manufacturing procedures.

Driving manufacturing with data is not an option; manufacturers who rely on guesswork instead of facts and figures will make poor decisions, leading ultimately to failure in the marketplace. It’s data—accurate, reliable, timely data—or death.

In a Nutshell

ISO 13399 is the result of development work led by several major cutting tool manufacturers (most notably Sandvik Coromant and Kennametal) and cooperating research organizations. Although this work began in the 1990s, rapid progress was made in the last five years, leading up to important updates to the standard in 2013-2014. The full name of the standard is ISO 13399, cutting tool data representation and exchange.

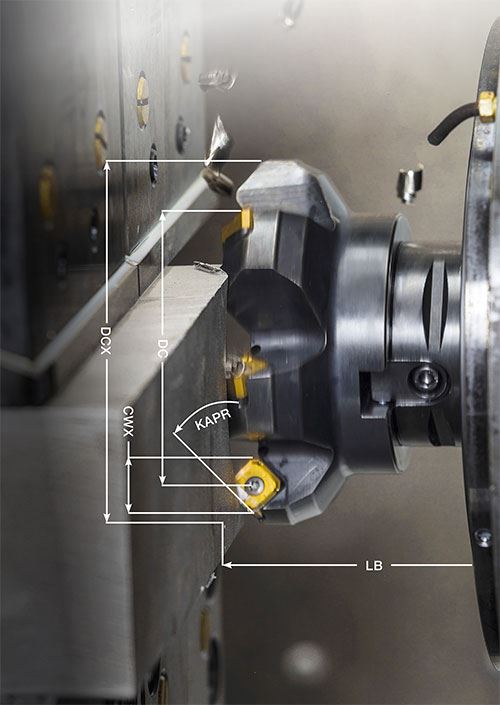

Essentially, the standard specifies a common format for the digital code that identifies and describes cutting tool components. It creates a universal language for talking about cutters and related components, laying down the meaning for the words used to name the parts, features and parameters related to cutting tools, and providing a single abbreviation for each term. The standard also spells out how critical dimensions of the cutting tool are defined and presented in numerical values. Using the same words and numbers with the same meanings reduces ambiguity and confusion when cutting tool data is used in software applications.

Consider this one example regarding a frequently used fact about a cutting tool: its shank length. By adopting ISO 13399, users agree that, for digital applications, the name for the length of the tool shank is “shank length,” which is given the code “LS.” Whereas one cutting tool manufacturer may say “length of shaft” in its catalogs or technical drawings, and another manufacturer says “shank” or “shank length,” all cutting tool manufacturers must use “shank length” and “LS” in their code for that part of the tool when exchanging data in order to comply with the standard. The current version of the standard has similar agreed-upon definitions and abbreviated codes for more than 420 terms related to cutting tools.

Using this standard brings clarity and uniformity to data about cutting tools. This should help eliminate misinterpretations about the meaning of these terms and codes when exchanging cutting tool data. In addition, the standard provides a framework for adding new definitions and codes as needed. So far, ISO 13399 covers only cutting tools, but work on adding other tool types to this family of standards is underway.

Most important, having the same language to talk about cutting tools means that this “talk” can be translated in a digital format that is readily usable by computer software applications. By using a common data format, these applications can recognize what information is contained in this digital translation, regardless of the source. For example, if a CAD system needs to know the length of a tool shaft to create a 3D virtual model of an end mill, the numerical value associated with “LS” in the database gives that number.

When ISO 13399-formatted data is stored in a database accessible to the software application, the transfer of this information is instant and automatic. There is no need for a programmer to look it up, interpret the meaning, find the code and enter the numbers. This exchange of data enables the software application to work faster and be more complete and accurate. The use of ISO 13399 will provide considerable cost savings by eliminating the need for repeated cutting tool data mapping for different computer systems or non-standardized cutting tool databases.

Let’s say the application is creating a 3D model of the cutting tool for a simulation of a pocket milling routine. It doesn’t matter to the software if that data represents a cutting tool product from this or that cutting tool supplier. The code and the numerical values can be found and applied without additional processing.

Likewise, building a library of cutting tools for a CAM system is greatly streamlined when all of the entries in that library can be acquired already formatted in the same way. Similarly, as software applications using standardized tool data are developed, users can expect faster re-ordering of tools, more accurate costing of tool consumption, and on-the-fly calculation of the ROI for pricier cutting tool items such as diamond-tipped inserts, among other useful reports. Likewise, cutting tool manufacturers will get reliable feedback on performance of their products in the field.

It appears that virtually all cutting tool manufacturers intend to adopt ISO 13399. Sandvik Coromant and its family of cutting tool brands has made all of its tool classification data available in the standardized format, as has Kennametal and its related brands. Other manufacturers are at various stages of completing this process. This is no small task, as manufacturers typically have many thousands of cutting tool items in their product offerings.

Let’s look at some other practical benefits that have been brought about now that cutting tool manufacturers have a common language in the same digital translation for their products.

Better Tool Selection in CAM

ISO 13399 can help CAM software users make better decisions about the cutting tools selected for CNC programming. Here are a few ways this will happen.

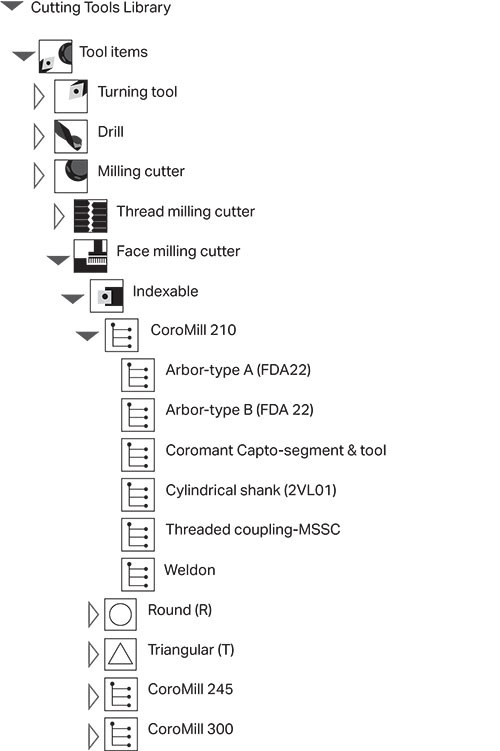

The standard makes it easier to build an internal tool library in CAM that gives the programmer more choices for machining operations. Typically, CAM software with a structure for a built-in tool library requires the user to enter data about cutting tools one item at a time. This involves finding the information from cutting tool catalogs or online product listings, interpreting the meanings of the different terms cutting tool manufacturers might use, and entering the information according to the structure of the CAM system’s library. This process can be slow, tedious and susceptible to data-entry errors. Data in the ISO 13399 format is easier to find, interpret and enter. More important, with the right interface, most CAM systems will be able to import this data directly from the cutting tool manufacturer.

However, many CAM systems are now moving beyond this step entirely by accessing open-platform cutting tool databases maintained online by the tool manufacturer in the ISO 13399 format. These Web-based databases facilitate the process of building and integrating this kind of cutting tool library for CAM. Because libraries built in these open-platform structures are based on the ISO 13399 format, compliant tool data from other manufacturers can be incorporated, as well.

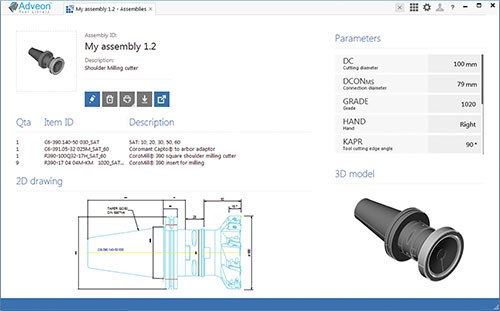

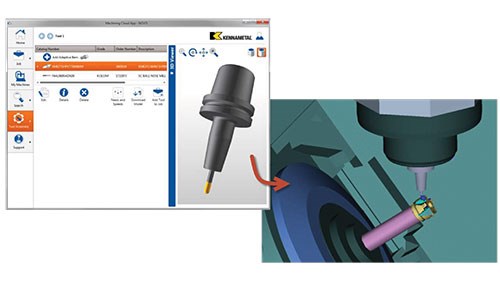

Examples of these platforms include Kennametal’s Novo and Adveon, a platform developed by Sandvik Coromant, which is open to data from any tool supplier, as long as it is according to the ISO13399 standard. Working with these platforms, the CAM user can download or enter data for tooling items that represent a shop’s “personalized” database of toolholders, adapters, cutting tools and inserts that are available on the shop floor. This enables the user to create tool assemblies from this library and view them in 2D or 3D renderings. These tool renderings, along with the tool data and application parameters, can then be easily imported into the CAM software for use in setup sheets and simulation. It is also possible to integrate an open-platform library directly in the user’s CAM system (if the CAM supplier offer this option), so that 3D models can be exported to the system’s simulation modules for more complete and accurate error checking. Adveon, for example, has been integrated with a number of CAM systems from leading developers.

The next step is support for tool recommendations and optimization in applications based on an online “data cloud,” which taps the massive capacity for data storage, analysis and calculation in shared, networked computing resources. Access to such a cloud-based tool library will enable the user to submit details about a machining operation and receive the best cutting tool options and the most appropriate parameters such as toolpath strategy and optimal speeds and feeds for the situation.

To describe its progress in this direction, Kennametal characterizes Novo as “process knowledge delivered via the cloud.” It provides cutting tool selection functions and operates like a process planner. It works from the part feature back to the machining strategy, and then recommends tools for each strategy. In addition, each project is tied to application data gathered from company experts whose experience stands behind the recommendations. When integrated with the user’s CAM software, designers or programmers will have access to this knowledge at the touch of a button without leaving their function.

The MTConnect Connection

Because ISO 13399 specifies a computer-interpretable, digital format for data describing cutting tool products, it simplifies the exchange of this data between computer systems and software applications. Information about cutting tool products from one manufacturer “looks” the same as the information from another manufacturer that also complies with this standard format. Computer software that can use this information does not have to have a translator or customized interface for the data from each manufacturer in order to make that data usable in an application. For this reason, ISO 13399 is a valuable resource and model for the other standards developed to exchange manufacturing data.

An important example of this is MTConnect. MTConnect is a computer protocol for exchanging data between shopfloor equipment such as machine tools and software applications for monitoring and analyzing machine performance. Like ISO 13399, MTConnect creates a vocabulary of defined terms related to manufacturing equipment. From the start, MTConnect was designed to be extensible, that is, sets of vocabulary terms could be added to the standard for other categories of manufacturing data.

After the original versions of MTConnect were released in 2008, one of the categories of new vocabulary terms targeted for inclusion in the MTConnect standard were those related to “mobile assets.” For MTConnect purposes, mobile assets include cutting tools, cutter body assemblies, fixturing components and other elements that tend to circulate among machine tools, storage units, inspection devices, automatic toolchangers and so on.

Developers found that ISO 13399 could provide a ready-made set of vocabulary terms and codes usable for an extension to MTConnect that would cover mobile assets. By adopting these terms and codes, the mobile assets extension could be compiled and released more quickly. This extension was formally added to the MTConnect standard in July, 2012.

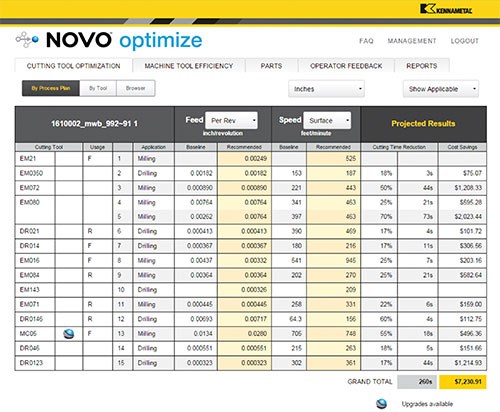

The compatibility between ISO 13399 and MTConnect is significant because it enables data about cutting tools and their performance to be added to the data that an application chooses to include in its monitoring and analysis. A glimpse at Kennametal’s Novo Optimize web portal shows how MTConnect and ISO 13399 come together as a move to data-driven manufacturing.

This portal enables a machine shop with an MTConnect-compliant machine monitoring system to link manufacturing planning with real-time feedback of cutting performance, thus identifying productivity improvements in machine and cutting tool usage. This information is accessible through any Internet-enabled device and is linked directly to each machine that is monitored. It streamlines the reporting of real-time and historical data of cutting tool performance in association with machine performance, so that Big Data analytics can be applied. By providing real-time analysis of machine efficiency, the system’s algorithms identify the actual performance of the cutting tool during material removal and derive recommendations based on demonstrated tool performance.

GTC—A Fix for the Missing Link

Open almost any catalog of cutting tool products from a tooling manufacturer and you will find that all of the tooling products listed inside are organized by type. Typically, the types of tools are grouped under a few major categories (tools for milling, tools for turning, tools for grooving and cut off, and so on). These major categories are then broken down into subcategories, which may be further divided into finer subcategories or subclasses. This hierarchical structure makes it easier to find the tool you are looking for.

ISO 13399 does not include a detailed hierarchical classification structure. It simply specifies a standard format for the individual specifications of tooling items that might appear in the manufacturer’s catalog. This means each listing does not indicate what kind of tool it is, whereas all of the listings in a catalog under End Mills, which is in the Milling Tools section, does offer that kind of indication. Classifying cutting tools helps the user find the right tool for the intended machining operation.

Computerized systems that use databases of information about cutting tools need some sort of hierarchical classification system to organize this information and make it easier to search. Because ISO 13399 does not currently provide a detailed classification system, a Generic Tool Classification has been developed and proposed to fill this gap.

Sandvik Coromant and Siemens PLM worked together to create this GTC as a complement to ISO 13399. Its structure was intended to be generic and brand-neutral, in keeping with the goal of making cutting tool data readily exchangeable between software applications. The developers of GTC consulted with other vendors, CAM suppliers and end users in this effort.

Briefly put, the classifications in GTC follow the basic logic behind the categories in cutting tool catalogs. However, the structure is designed for use in computer databases and therefore is patterned after the structure specified in ISO 13999 and other international standards. You can think of the structure of GTC as a tree with several levels of branches. The leaves at the tips of the branches, so to speak, are the individual tool item listings in the format specified by ISO 13399.

At the moment, GTC has not been formally adopted as a standard nor made a part of ISO 13399. A neutral organization has to be established to finalize its preparation and to maintain it. GTC has to be harmonized with certain other classification systems that might include cutting tools but do not go to the same level of categorization.

The Full Significance

The concept of data-driven manufacturing is a means, not an end. It is a means to making better decisions that lead to more efficient, more productive activity on the factory floor. For shops and plants that are implementing the principles of lean manufacturing, the technology that enables data to drive manufacturing also provides a boost to lean practices, simply because much of the waste that occurs in manufacturing can be traced to miscommunication or the lack of reliable data. However, having the right facts and figures (and being able to share them) leads to better decisions. Better decisions mean less waste.

Any hindrance to the exchange of digital data between computerized equipment and across information systems is a barrier to data-driven manufacturing. Data exchange standards such as ISO 13399 help break down these barriers. Given the especially broad influence that critical decisions about cutting tools have on manufacturing with machine tools, ISO 13399 stands out as a major step toward achieving higher levels of data-driven manufacturing.

Data exchangeability is also a key enabler in concepts such as the Internet of Things and initiatives such as Industry 4.0. Neither of these can be realized fully without the smooth, secure and comprehensive flow of data. Likewise, access to the data cloud hinges on data exchangeability. In this context, ISO 13399 and other data exchange standards for manufacturing show their true significance.

Related Content

OSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

Read MoreNidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

Read MoreGWS Tool Group End Mill Provides Dynamic Milling

Eastec 2023: The Hurrimill AT4 all-terrain end mill features radial-end gashing, which enables drilling, steep ramping and aggressive helical entry.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Standard Tool Classification for Better Data Communication

Cutting tool manufacturers have worked together to create a generic tool catalog format that helps link cutting tool information with applications supporting data-driven manufacturing.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More