The Anatomy of an End Mill for Titanium

Titanium is often characterized as a “challenging workpiece material.” Certainly, machining this material is a challenge to milling machines, cutting tools and workholding accessories that are suitable for machining more common materials such as mild steel, cast iron or aluminum.

Share

Titanium is often characterized as a “challenging workpiece material.” Certainly, machining this material is a challenge to milling machines, cutting tools and workholding accessories that are suitable for machining more common materials such as mild steel, cast iron or aluminum. With appropriate machines, cutters and related equipment, however, machining titanium can be a successful and profitable operation for the knowledgeable and committed machine shop.

The key is understanding the nature of titanium and the somewhat complex interactions among the components of the machining system that titanium calls for. Examining one end mill family specifically designed and engineered for titanium milling brings out many of these interactions. That is, the features and characteristics of these end mills reflect the implications of a complete system optimized for titanium machining.

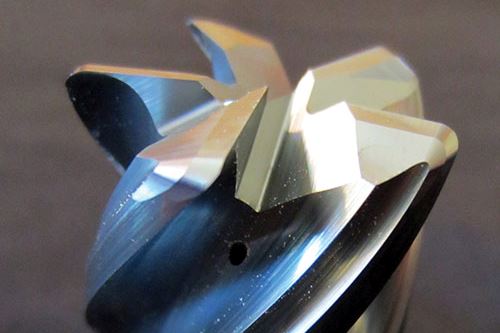

This representative end mill family is VariMill II ER from Widia (Latrobe, Pennsylvania). It is the five-flute expansion of the original four-flute VariMiIl, hence the II. The five flutes are unequally spaced. ER stands for eccentric relief—the version of this end mill that is best-suited for titanium because the eccentric relief gives the cutting edges extra strength for the high feeds at relatively low rpms that titanium requires. Though primarily designed for roughing and finishing applications in titanium aerospace parts, it can be used for slotting, ramping and plunging of titanium and stainless steel in virtually any industry.

David Buchberger, who represents Widia through Hi-Speed Corp. (Thousand Oaks, California), specializes in advising aerospace shops in titanium cutting. He explains why this cutter work so well in titanium. For example, the correct cutting edge for titanium is important because this material tends to work-harden, he says. Titanium quickly loses what low malleability it has when “beaten” by cutting speeds that are too high. “Titanium likes a big chip to clear material before it hardens. A strong, sharp edge, with the thrust of a rigid, high-torque machine structure to power it, can shear the titanium effectively,” he says. The eccentric relief on the edges of the VariMill II ER creates positive orientation on the radial and axial angles of this edge, which promotes this shearing action.

The underlying foundation for strong, sharp edges, however, has to be a tool with a strong, thick core that makes the entire tool rigid. For this reason, the flutes are more open at the tip of the tool where space for chip evacuation is needed, but as the core runs up to the shank, it becomes heavier to provide integrity to the tool and resistance to deflection, Mr. Buchberger explains.

The flutes are unequally spaced to create a consistently variable impact on the workpiece that breaks up any regular frequency that might match a harmonic in the machine structure to create vibration, detectable as chatter. Of course, other sources of chatter, such as weaknesses in the machine structure or clamping methods, must be addressed in the system.

The coating on the end mill plays a role as well. The VariMill II ER end mills are coated with AlTiN (aluminum titanium nitride), which helps keep the edges sharp by resisting cracking and, more importantly, making surfaces that contact the workpiece smooth and slick so they generate less frictional heat. “Heat buildup accelerates deterioration of the cutting edges, so controlling friction reduces one of the negative factors that shortens tool life,” Mr. Buchberger says.

Because these end mills are designed to be center-cutting, an inspection of the flat end of the tool shows a strong web across the root. This design eliminates a dead spot in the center that might drag across the floor of a pocket or bottom of a slot. The edges along the tip must also be prepped for sharpness and strength.

As a standard item, the VariMill II ER end mill offers the Haimer SafeLock anti-pullout clamping feature on tools 0.5 inch (12 mm) and larger in diameter. “This system gives the tool more stability and greater concentricity in the holder, in addition to countering pullout forces, so its benefits are multidimensional,” Mr. Buchberger says.

He adds that the primary concern for the programmer is having the correct speeds and feeds. “The concept is to spin the tool slowly and take big bites. A surface speed of 160 to 200 fpm is the best range.” He says this is more important than elaborate toolpath strategies.

Finally, he stresses that any approach to machining titanium must be a complete system—the right tool, the right machine, the right clamping and so on. “When shops take care to do titanium milling right and invest in the appropriate technology, which includes carefully chosen cutting tools, they will have a system that makes machining titanium no more challenging than other operations,” he says. “The challenge is understanding a systematic approach and implementing it fully in the first place. He also suggests working with a cutting tool supplier who will base tooling recommendations on a review of the entire titanium machining operation. “Any weak link in the process can be disastrous. No cutting tool is the best or right choice if other elements of the system are sub-optimal, he concludes.

The VariMill II ER covers more than 100 standard line items ranging from 3/8 to 1.0 inch (10 to 25 mm) in diameter and is available globally.

Related Content

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreHigh-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)