Successfully Feeding The Medical Market

This medical shop has adopted five-axis, bar-fed machining technology to adapt to compressed delivery schedules and increasingly complex part geometries.

Share

A visit to Structure Medical’s facility in Naples, Florida, highlighted a few challenges faced by modern medical machine shops. How Structure Medical has positioned itself to meet those challenges shone through as well. Consider these issues:

- Design complexity of machined medical components is increasing to the point that some shops won’t even bid on the machining work. This means medical shops must adopt advanced machining technologies if they want to produce components that other shops can’t even imagine tackling.

- The rush to speed new medical devices to market is compounded by the fact that component designs often change after a job has been quoted. This means medical shops must maintain close relationships with their customers and invest the programming time at very early stages of a project to quickly ramp up production after a new design is finalized.

- Lot sizes for medical components range from one-off prototypes to short runs to high production. This means medical shops must be flexible enough to be efficient in all three of these supply scenarios.

In the paragraphs that follow, Kevin Confoy, Structure Medical’s general manager, explains how important it is for machine shops to adopt the aforementioned italicized points. These are some of the practices Structure Medical has adopted to best support medical device manufacturers during their new product launches.

Once a medical device manufacturer receives FDA approval for its new product, the manufacturer wants to deliver those devices to the hospitals (its customers) as soon as possible. How quickly this happens largely depends on shop responsiveness. Structure Medical will immediately generate the entire CAM program from the initial component designs it receives from its customers. The shop invests in this programming time realizing that the design of that component will likely change a few times before any machining work is performed. This reduces time to market because it is quicker to make minor changes to an existing program than waiting until the design is finalized before developing the entire part program. Besides, the FDA won’t allow a manufacturer to make wholesale changes to a device once it has been approved.

With the design finalized, component prototypes are machined for customer approval. After receiving approval, the shop must ramp up production quickly so that the device manufacturers can deliver relatively large batches of devices to the hospitals. Shops must switch from prototype to high production in short order.

Once the initial batch of devices is in the field, delivery requirements for their machined components change. As hospitals begin consuming the devices, the manufacturers send replacements and charge the hospitals for the devices at that time. At this point the shop is called on to help replenish the supply. Monthly lot sizes in this replenishment mode might be only 5 to 10 percent of the launch quantity.

The key is to have equipment that offers both the capability of machining complex components and the flexibility to be effective in a variety of production schedules. Structure Medical achieves this at its Naples facility by applying an atypical five-axis machine tool platform.

Bar-Fed Machining Technology

Len Zaiser is Structure Medical’s owner and founder. According to Mr. Zaiser, what sets his shop apart from the rest is the application of machine tools specifically designed for true five-axis machining (versus three-axis machines adapted for five-axis work). In fact, some of the parts the shop machines couldn’t be produced without five-axes of simultaneous movement. Mr. Zaiser’s second facility in Mooresville, North Carolina, uses five-axis machines from Mitsui Seiki and SIP. His Naples facility houses a different style of machining center—bar-fed models from Willemin-Macodel that allow complete machining of complex components from barstock.

The company has added four of these Willemin W-408 machines over the last two years. Two of them can perform both milling and turning operations; the other two are purely mills. The shop is an early adopter of this bar-fed machining technology. In fact, the two mill/turn versions are the first to be installed in a U.S. shop.

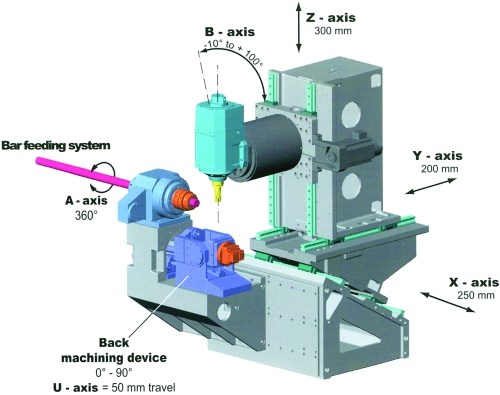

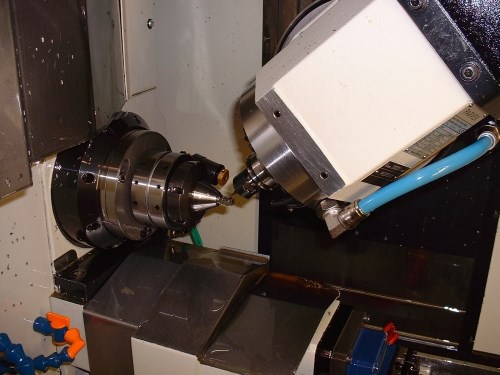

The machines use a bar feeder in much the same way as a lathe. The bar feeder pushes barstock as large as 1-1/8 inch in diameter into the machining zone to allow the milling spindle to access five sides of the part. The fourth and fifth axes of motion come from 360 degrees of A-axis barstock rotation and -10 degrees to +100 degrees of B-axis spindle movement. The milling spindle offers speeds as high as 30,000 rpm as well as 10 kW of power and 4.2 Nm of torque. The mill/turn versions are capable of 6,000 rpm of A-axis rotation for turning operations.

The shop benefits from this bar-fed machining center platform in a number of ways. The bar feeder allows long stretches of unattended operation when high production is needed. Because components are produced from barstock, typical workpiece fixturing and setup hassles are reduced. This is particularly important when dealing with the complex geometries of medical components.

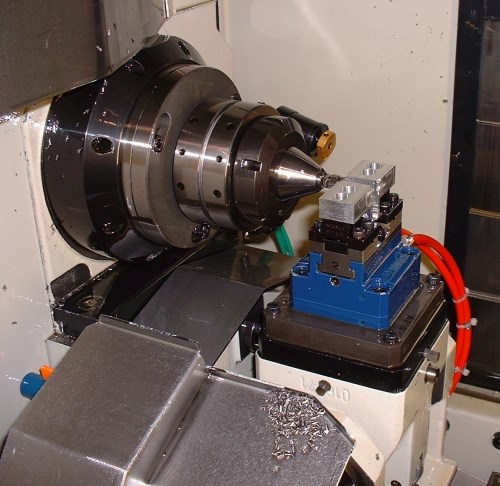

These machines are often able to completely machine components from barstock by using an optional backworking device. How this backworking device operates is illustrated in the series of photos on the following page. Once the bar is fed into the machining zone and machining on five sides of the part is completed, the part is gripped by the backworking vise and sawn from the barstock. The vise then pivots to allow machining of the final side and the completed part is dropped into a collection chute.

Each of the four machines is equipped with a Blum laser toolsetter. The ability to detect broken or worn tools is especially important when running in unattended mode. In addition, a 24-tool automatic tool change magazine allows sister tooling to be called up to replace a broken or worn tool during long spans of unattended operation.

The four Willemin machines are positioned in the shop two wide and two deep. There’s really no need to organize them into a cell-type layout because each machine can be thought of as a cell. In many cases, one operator tends all four machines.

Prototyping helps Structure Medical reduce its delivery times. In fact, one of the mill/turn machines is dedicated to prototype work. The shop has also found that prototyping allows it to perfect machining methods that will be used during high production. It machines prototypes from the material specified for production. The vast majority of components are machined from titanium ELI (Extra Low Interstitial), which is an alloy commonly used for medical applications.

CAM programming proved to be an initial hurdle in adopting this alternate machine platform. Structure Medical has since standardized on Mastercam from CNC Software, Inc., and currently uses the Mastercam X version. All programmers use the same software platform so that one can easily pick up a job from another who is out of the office or no longer with the company.

Aiming For No Returns

Although the components have excellent surface finish right off the machines, Structure Medical improves on that finish using equipment from Otec. The company performs 100-percent inspection of components before shipping them to the anodizer. Once the parts return from the anodizer, shop employees wear gloves to prevent oils from contacting the parts. The shop then laser etches the anodized parts prior to packaging and delivery to its customers.

Related Content

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

Video of a Really Cool Bar (-Fed Machining Center)

See a five-axis, bar-fed machining center creating a complex sample part complete from barstock.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)