-

-

-

SPONSORED

-

Machining Centers

Increase Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

Read MoreFive-Axis Blends Require Minding Ballnose Tolerances

Proper symmetry, expressed via the end mill’s diameter and radius tolerance, is critical to ensure smooth surface finishes during five-axis contouring operations.

Read MoreVideo: Accelerated Blisk Milling

CAM and cutting tool companies develop a process for machining a titanium bladed disk in less than half the conventionally expected cycle time.

WatchGantry Machine Streamlines Mold Production

Century Tool and Gage's large-size plates used in the injection-molding process were causing production bottlenecks. The Annihilator gantry machining center from Quickmill improved productivity and quality.

Read MoreVMC Helps Shop Find Tight-Tolerance Niche

YDC Precision Machine's VMCs needed more capacity and capability, so it invested in a Makino PS95 vertical machining center that cut cycle times in half.

Read MoreVMC’s Improved Automatic Pallet Changer Handles Heavier Loads

Hardinge offers Bridgeport’s fully digital Conquest V480 APC E series vertical machining center with Mitsubishi M70 CNC.

Read MoreMulti-Function Machines Turn, Mill and Grind

MCM offers a range of four- and five-axis machines, as well as multitasking machine models that can turn, mill and grind.

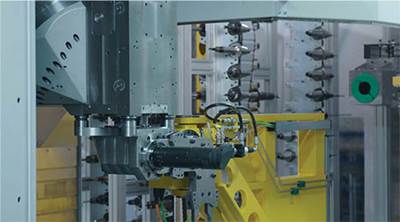

Read MoreTechnology for Turning on a Five-Axis Machine

A turning tool adapter that mounts to the MCT five-axis machine isolates the main spindle bearing from the shock of turning operations.

Read MoreVMC Improves Shop’s Flexibility, Efficiency

RDM Manufacturing Precision CNC needed to improve its equipment flexibility to keep up with its large variety of clients. Investing in a VMC from SMTCL enabled the shop to achieve higher metal removal rates and better surface finish to better deal with demand.

Read MoreHMC Accurately Machines Large Parts

The GE590H, Enshu’s largest horizontal machining center, is designed for large-part applications that demand both high-volume metal removal as well as precision.

Read More