Machining Centers

Five-Axis Machining Center Provides Torsion-Resistant Column

The Tongtai CT-350 VMC, available from Absolute Machine Tools, offers a small footprint and five-axis machining capability.

Read MoreVMC Offers Continuous Surface Machining of Complex Workpieces

SNK America’s CMV-100 vertical machining center is said to provide efficient, precise five-axis machining and contouring in applications such as three-dimensional work profiles for dies and molds, aircraft components, and more.

Read MoreLarge-Part HMC Offers Quick Positioning at High Feed Rates

The Mazak HCN-6800 heavy-duty HMC is designed to deliver the power and versatility needed for productive and precise large-part machining.

Read MoreHeavy-Duty VMC Provides High-Accuracy Positioning

The Johnford SV-60H vertical machining center, available from Absolute Machine Tools, is designed for durability, rigidity and capacity combined with speed.

Read MoreSmaller Machining Center Maintains High Volumetric Accuracy

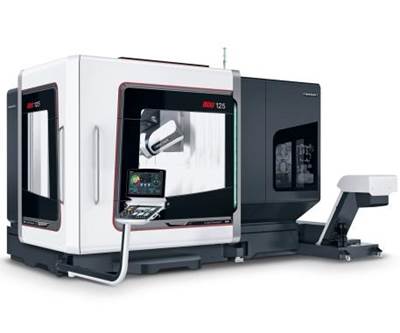

DMG MORI has extended the high-precision machining centers in its Dixi series to include the smaller Dixi 125 for workpieces with diameters ranging to 1,250 mm.

Read MoreDrilling Machine Changes from BTA to Gundrill Tooling without Dismantling

Unisig has added the high-precision UNI-50BTA to its UNI series of deep-hole drilling machines.

Read MoreShorter Lead Times for Custom Metal Blanks

With the help of newly-acquired duplex milling technology, TCI Precision Metals offers shorter lead times for its custom machine-ready blanks.

Read MoreTaking It Slow Pays Off for Learning Five-Axis Machining

A deliberately incremental approach helped this shop flatten a significant learning curve for collaborating on the postprocessor, easing setups and using cutting tools effectively.

Read MoreIncrease Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

Read MoreFive-Axis Blends Require Minding Ballnose Tolerances

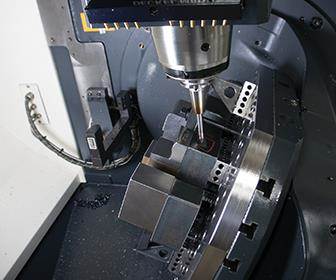

Proper symmetry, expressed via the end mill’s diameter and radius tolerance, is critical to ensure smooth surface finishes during five-axis contouring operations.

Read More

.jpg;maxWidth=300;quality=90)