Gantry Machine Streamlines Mold Production

Century Tool and Gage's large-size plates used in the injection-molding process were causing production bottlenecks. The Annihilator gantry machining center from Quickmill improved productivity and quality.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreUnderstanding that technology and time-saving investments are the key to keeping up with increased customer demand has helped Century Tool and Gage become the large compression mold manufacturer that it is. This knowledge came in handy recently when CNC department manager Mickey Guckian saw that the company’s lineup of machines couldn’t accommodate large plates in an efficient manner. By investing in a gantry machining center from Quickmill, the company was able to handle such part sizes without the production bottleneck.

Located in Fenton, Michigan, Century manufactures compression molds and secondary tooling for the automotive, heavy truck, aerospace, agricultural and housing industries. The location accommodates more than 100 employees, 18 CNC machining centers, 29 CAD/CAM workstations and a try-out mold press facility.

The upswing in the North American automotive industry during the past several years has caused an increase in demand for Century’s services, such as manufacturing the large parts required for compression molds. Mold bases can measure 100 by 120 by 15 inches and weigh more than 25,000 pounds, and various mold plates can measure 100 by 150 by 4 inches and weigh more than 12,000 pounds. As orders for more parts began coming through the company’s door, the challenge became producing clamping, injection and pin plates efficiently. Century realized it needed a machine that was able to mill, drill and tap the large plates that were frequently taking up time on its C-frame roughing machines. Even with four CNC C-frame machining centers, two five-axis machining centers and two gantry machining centers, processing the plates still caused a bottleneck. The C-frame and five-axis machines were constantly running, milling molds and large plates, and the gantry machining center took as long as 15 hours per plate on the sizes it could accommodate.

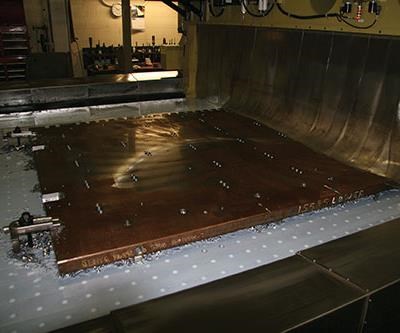

As Century began looking for a new machine, it focused on two main features: It had to be able to handle the large-sized plates, and it had to be able to do so with minimal setup time to ensure production did not slow. Ultimately, the company had to decide between a horizontal and a gantry machining center, eventually settling on the gantry style due to the simplicity and ease of part setup. Specifically, the company chose the Annihilator 120-180-30 gantry machining center from Quickmill (Peterborough, Ontario, Canada) for its rigid and time-saving design; part-loading simplicity; table size; and geared, 50-hp spindle. The fact that Century already had been running a Quickmill 96-180-24 machining center for the past 17 years was also an important factor in the decision.

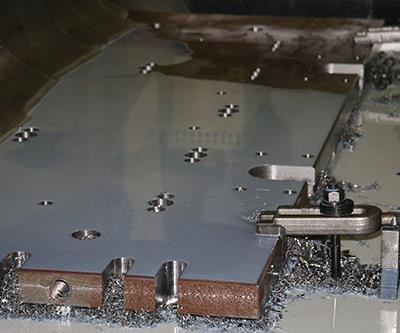

The Annihilator’s 180-inch-long table easily accommodates the 150-inch plates in one setup. With the bridge set to one end of the table, plates are loaded via an overhead crane and clamped to the drilled and tapped table. Previous operations required larger plates to be set up multiple times due to the limited table size of the C-frame machines. Setup time has now dropped by one hour per plate, the company says.

Another key feature of the Annihilator is its 20-tool, carousel-style automatic toolchanger. It keeps operators from having to manually change as many as 15 tools during plate production, decreasing production time by 10 percent per plate.

Compared to plate operations performed on Century’s older gantry-style machining centers, the new Annihilator provides far more milling and drilling capabilities. It can produce clamp slots, ejector-pin pockets, key pockets and bushing pockets using machining operations such as face milling, drilling, tapping, reaming and circular interpolation. According to Mr. Guckian, the machine’s rigid design, 50-hp spindle and gearbox, as well as the ATC, are the main features that have contributed to reduced plate production time. On average, plates are produced 30 percent quicker than before, while some sizes have achieved 50 percent time savings. Clamp slots, for example, now take seven minutes per slot to complete, compared to 15 minutes previously. With 10 to 50 clamp slots per plate, the time savings really add up, the company says. In one example, clamp-slot milling on a mid-sized clamp plate had dropped from 15 to six hours.

Since acquiring the Annihilator machining center, the company says new opportunities for faster production have presented themselves. Prior to the new gantry machining center, the company rough-milled the molds on the C-frame machines. The Quickmill gantry can face mill mold bases, riser assemblies and injector boxes, freeing valuable time on other machining centers. Future plans for the Annihilator include detail work on the bottom of mold bases, including mounting holes and pocketing.

Related Content

Volumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)