Machines

Video: Linear Motor Micromachining Center

Video shows the smooth, quiet, rapid motion characteristic of effective micromilling.

WatchDie/Mold Shop Joins Constant Velocity Revolution

According to machine tool supplier GBI Cincinnati, data processing inefficiency inherent in many CNCs can cause actual feeds and speeds to vary significantly from those called for in the part program, leading to acceleration and deceleration during the cut. GBI’s Revolution machine, which features a high speed control designed to keep feeds and speeds closer to programmed rates, has helped this shop significantly improve cycle time and tool life on demanding prototyping applications.

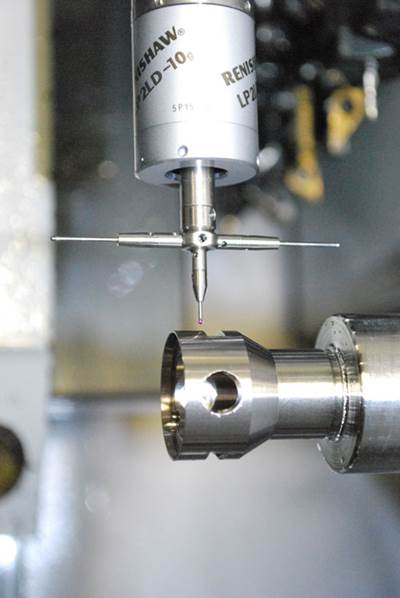

Read MoreProbing Beyond Prismatic

This manufacturer has used on-machine probing to help automate setups and maintain process control for prismatic parts produced on VMCs for years. The metrology products maker recently implemented probing strategies that let it achieve similar results on its turn-mills and Swiss-types. The smaller, more economical batch sizes these machines now produce are better aligned with true production requirements.

Read MoreRigidity Required When Grinding Challenging Materials

Effective centerless grinding of hard materials requires a machine that is capable of damping process vibration at high wheel speeds and providing the rigidity to withstand very high cutting forces.

Read MoreTaking CNC To The Next Level On A Multi-Spindle

A new generation of multi-spindle automatic lathes from the Czech Republic may change the thinking about the best way to produce complex parts in small to medium volumes. An innovative drive system on these machines enables users to optimize spindle speeds for specific machining operations.

Read MoreCompact Turn-Mill Center

The entry-level Nakamura-Tome TW-8 multitasking turn-mill center from Methods Machine Tools is said to reduce cycle times. An opposed, two-spindle, two-turret construction allows the centers to perform like two single spindle machines within a compact footprint, the company says. The system features a Fanuc 31iA control that offers standard conversational programming.

Read MoreThreading A Horizontal Wire EDM

A wire EDM machine designed for micromachining uses negative air pressure to thread the fine wire.

WatchHigh Performance Turning

The TMX series of slant-bed lathes from Hurco includes three turning centers: TMX8, TMX8MY and TMX8MYS, all of which include construction and high-performance specifications for efficiency. Specifications include rapids of 950 ipm (X axis) and 1,200 ipm (Z axis), a spindle speed of 14,500 rpm and a 36-hp spindle motor. The all-digital control, drives and motors along with absolute encoders on all linear axes provide superior surface finish capability, the company says.

Read MoreLathe Incorporates Electronic Servo Motor, Threading Computer

The Hardinge Group has replaced the mechanical gearbox in the HLV toolroom lathe with an electronic servomotor and threading computer. This is said to both eliminate the need to purchase gears for different inch or metric threads and to ease left-hand threading. Thread range is 0.

Read MoreFive-Axis Turn/Mill Center

GBI Cincinnati’s five-axis, traveling-column machining center, the matec-30 HV/K, has torque drives in the swiveling axes (swivel head and rotary table) and is suited for precise mold work and mixed-volume, short run operations. With X-, Y- and Z-axis travels of 1,300, 600 and 800 mm, respectively, the center combines high-performance turning/milling and large machining capacity within a compact, 4,900- × 4,355- × 3,250-mm footprint. The 1,515- × 635-mm table with five T slots can handle a maximum table load of 1,000 kg.

Read More