Rigidity Required When Grinding Challenging Materials

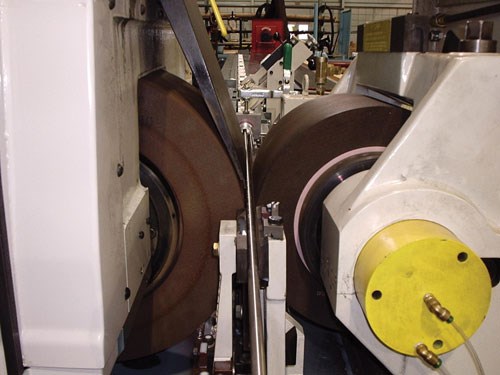

Effective centerless grinding of hard materials requires a machine that is capable of damping process vibration at high wheel speeds and providing the rigidity to withstand very high cutting forces.

Share

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreManufacturers in a variety of industries are increasingly integrating difficult-to-machine materials into their new product designs. Greg Payne points out that this presents opportunities to shops that have the equipment and know-how to machine titanium, tungsten carbide, stainless steel and even more exotic materials such as hafnium that design engineers are specifying. Mr. Payne is the centerless grinders products manager for Cinetic Landis Corp., headquartered in Hagerstown, Maryland. He says machine rigidity is the key to effective centerless through-feed, in-feed and form-grinding operations of these materials.

The first inclination when developing a centerless grinding process for challenging materials often is to increase wheel speed, Mr. Payne explains. Modifications such as adding air/oil-lubricated spindle bearings can allow older equipment to achieve speeds as high as 12,000 SFPM. (Speeds as high as 20,000 SFPM are possible using new centerless equipment.) However, when grinding hard materials such as tungsten carbide, a machine must not only be capable of damping process vibration effectively at high wheel speeds, but also withstanding very high cutting forces. It takes a great deal of force to enable even a diamond wheel’s abrasive grains to penetrate the surface of tungsten carbide. This is why it is important to consider overall machine rigidity and stability for these applications.

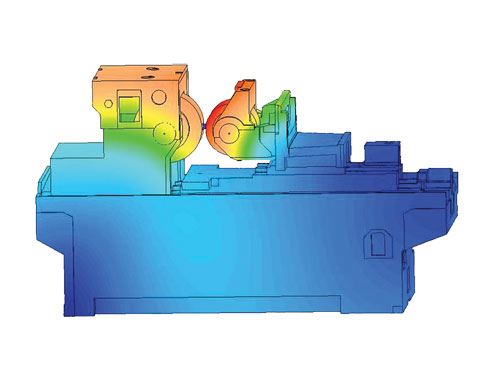

Mr. Payne says design elements of the company’s Landis Cincinnati Viking and RK series of centerless grinding machines provide a rigid platform for processing difficult materials. For instance, their one-piece, cast iron base has a honeycomb of ribs that is filled with a stiff composite material possessing extremely low thermal conductivity. While other grinding machines also use cast iron bases, Mr. Payne says the cavities in those bases are often added only where needed to contain fluids, to accommodate wire runs and piping, or to simplify the casting process. They typically are not located in targeted areas to optimize stiffness and thermal stability, he notes.

The precise fit of moving elements also contributes to overall machine rigidity. Mr. Payne explains that while hand scraping of machined bearing surfaces is the most popular means to achieve a close fit, the fit produced via hand scraping provides only 50 to 60 percent of contact. Replication, a new technology in which one bearing surface is precisely machined while its mating surface is replicated in a low-friction material, is said to achieve 100 percent of contact. This technology, which nearly eliminates stick-slip issues, is used for most mating surfaces that demand a precise fit on the Viking and RK series machines.

An open-architecture, PC-based CNC allows users to fully realize the capabilities of those machines, offering programming flexibility while providing networking and embedded data-logging functions. That said, rebuilding an older centerless grinding machine and adding a new control often doesn’t deliver desired results for processing hard materials, Mr. Payne notes, because the machine structure still lacks requisite stability.

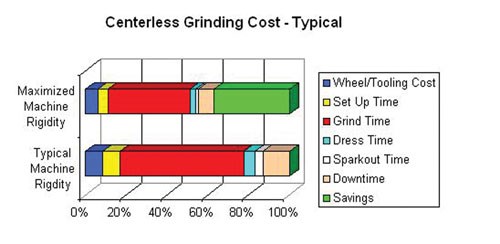

Mr. Payne says users of the company’s Viking and RK series centerless machines have achieved tolerances of ±0.0001 inch on titanium parts, experienced more than doubled the throughput on large-diameter titanium parts, and increased through-feed rate of carbide parts requiring high stock removal by 150 percent. Improvements are also possible when grinding less-demanding alloys. For these applications, a stiff machine provides higher output while maintaining process consistency and accuracy.

Related Content

4 Rules for Running a Successful Machine Shop

Take time to optimize your shop’s structure to effectively meet demand while causing the least amount of stress in the shop.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreWhat are Harmonics in Milling?

Milling-force harmonics always exist. Understanding the source of milling harmonics and their relationship to vibration can help improve parameter selection.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)