Inspection and Measurement

Probing Beyond Prismatic

This manufacturer has used on-machine probing to help automate setups and maintain process control for prismatic parts produced on VMCs for years. The metrology products maker recently implemented probing strategies that let it achieve similar results on its turn-mills and Swiss-types. The smaller, more economical batch sizes these machines now produce are better aligned with true production requirements.

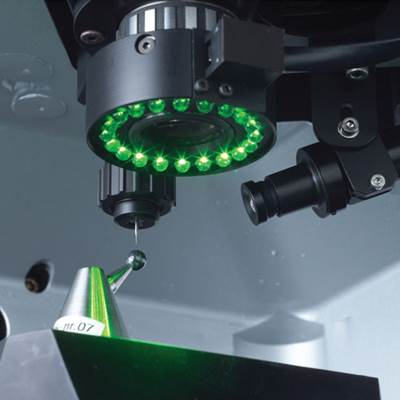

Read MoreMulti-Sensor CMM Eases Micro-Measuring

By combining an optical sensor and a touch probe, the F25 CMM from Carl Zeiss enables users to use the same machine platform to perform metrology operations on a variety of miniature parts.

Read MoreVision System Brings On-Machine Measurement To Ram EDM

Vision technology tailored to ram EDM allows shops to measure a part as it remains fixtured on a spark-erosion machine.

Read MoreCompact Gaging System Allows In-Process Inspection On Small Grinding Machines

This new gaging system not only is compact enough to install on small grinding machines, but also can measure a part’s OD, ID and length to sub-micron accuracy.

Read MoreLaser On Multi-Sensor Inspection Systems Works In Deep Slots

A new laser system gives multi-sensor measurement equipment more flexibility. This system improves the equipment's ability to measure deep recesses and features with high walls.

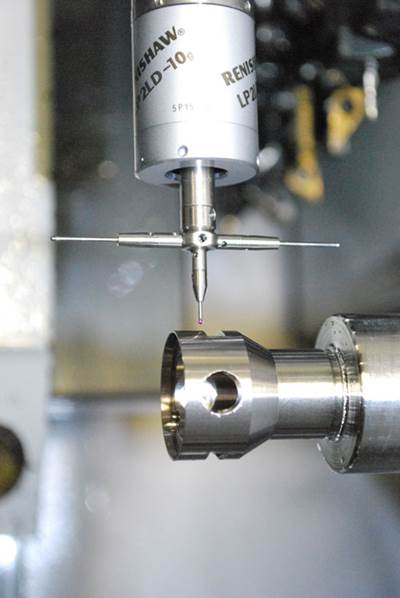

Read MoreStar Probes Feature Removable Styli

The company’s ultra-light CMM star probes are designed with removable styli. Sometimes tactile CMMs use star probes that often have five ruby ball styli to access virtually all exposed sides of a workpiece being measured. In traditional star probes, if just one ruby ball stylus is damaged, the entire star probe must be replaced, the company says.

Read MoreIntegrated Technology For Machine Tool Probing

Designed for small machining centers and inspection of hard-to-reach part features, the OMP400 optical probe is said to combine miniaturization of the OMP40 probe with advances in strain gage technology. It is suited for machines with short, Z-axis travel and spindles as small as HSK 32. Combining its size, accuracy, reliability and robustness, the probe is suited for high-accuracy applications.

Read MoreLaser Calibration And Volumetric Error Compensation

The MCV-5002 is suited for the laser calibration and 3D volumetric error compensation of CNC machine tools, CMMs and five-axis, gantry-type machines for the aerospace industry. This system is said to be efficient at calibrating and compensating linear, straightness, squareness and angular errors. The compact LICS-100A is designed for the laser calibration and compensation of pitch errors or displacement errors of machining centers, CNC machine tools, CMMs and other machines.

Read MoreImprove XRF Hand-Held Performance

The company’s Niton XL3t series material analyzers with geometrically optimized large area drift detector (GOLDD) technology are said to deliver improvements in light element detection, overall sensitivity and measurement times. This instrument offers light element detection of magnesium, aluminum, silicon, phosphorus and sulfur without helium or vacuum purging. For the machining industry, the capability to verify sulfur content in free machining steels, such as SS 303, can help eliminate damage to tooling caused by incorrect materials, the company says.

Read MoreOptical Twin Probe System

An integrated probing system enables the installation of both tool setting and part inspection probes onto machine tools using a single wireless interface unit. The Mida Optical Twin Probe System, which incorporates a compact, tube-type optical receiver interface (ORI), is said to simplify probing applications, especially in situations where connecting cables proves to be difficult, such as installations on machines with rotary tables or dual pallets. This combination is said to facilitate the speedy measurement of tool length and diameter, breakage detection and part setup and inspection times.

Read More