Multi-Sensor CMM Eases Micro-Measuring

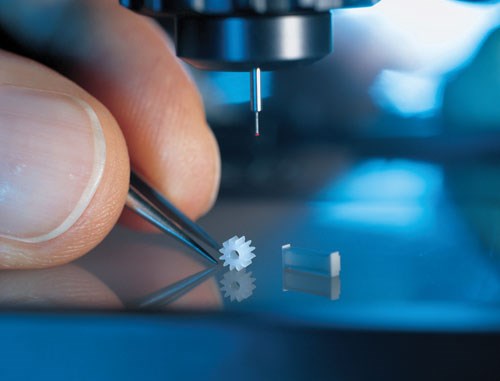

By combining an optical sensor and a touch probe, the F25 CMM from Carl Zeiss enables users to use the same machine platform to perform metrology operations on a variety of miniature parts.

Share

Machining on a micro scale is challenging enough, but very small parts also create special metrology challenges. The relatively large size of most traditional CMMs makes it challenging to accurately measure the geometry of such components, which often require smaller sensors and a higher degree of precision than larger parts.

To meet increasing demand in the medical, electronics, aerospace and other industries, Carl Zeiss (Maple Grove, Minnesota) offers a CMM designed specifically to meet stringent quality assurance standards for small, intricate workpieces. According to the company, the F25’s precise kinematics and high accuracy enable measuring uncertainty of 250 nanometers at a resolution of 2.5 nanometers.

For versatility, the F25 CMM is equipped with both contact and optical measurement sensors. Gerrit deGlee, new product manager at Zeiss, says this provides "the best of both worlds" when performing the 3D coordinate measurement for which the machine is designed. Depending on the application, the two sensors can be used independently or in concert with one another. To simplify part programming, an additional camera provides a better view of miniature features.

The optical sensor consists of a ViScan camera and an objective lens. It allows users to perform surface, edge and other 2D measurements and to reach features that are simply too small or sensitive to access with a touch probe. Mr. deGlee says the optics have been optimized for depth of field and have minimal distortion to ensure accurate results with maximum resolution in reflected and transmitted light.

However, while optical gaging has historically been the method of choice for small parts, especially softer components prone to damage or distortion, it has significant limitations, Mr. deGlee says. "With optics, you can’t measure the third dimension, or you have a very limited capability to do so," he explains. "Attributes like positional tolerances, perpendicularity, true position, cylindricity and flatness in that third dimension—or even in the X-Y plane—are difficult, if not impossible, to measure optically in many instances."

That’s where the system’s tactile sensor comes into play. The probe can accommodate stylus diameters ranging from 50 to 500 microns and stylus tip diameters ranging from 100 to 700 microns. While many touch probes have limited Z-axis measuring capability, the F25’s piezoresistive sensor is precise in all three axes, Mr. deGlee says. Additionally, the sensor is capable both of single-point measurement, in which it touches multiple points to measure geometry, and scanning, in which it continuously collects data while sliding along in constant contact with the part surface.

The probe is sensitive enough to read part geometry despite the fact that the force it applies to the workpiece can be as low as 0.5 mN/µm, or more than 100 times less than that of a standard CMM probe, Mr. deGlee says. This low contact force helps avoid damaging or distorting small, sensitive parts. Moreover, it allows users to hold workpieces with low-pressure fixtures, reducing the risk of part damage or distortion resulting from too much clamping force.

Accommodating this tiny stylus without breaking it requires a drive system that reacts rapidly to signals sent from the sensor, Mr. deGlee says. That’s why the F25 features linear drives, as opposed to ballscrews, friction drives or other traditional motion systems. "With linear drives, there are no wires that are being pushed or pulled when the machine moves," Mr. deGlee says. "It eliminates or minimizes noise in the drive systems, and that is critical for very precise measurements."

Mr. deGlee says another notable feature of the machine is its structural design, which ensures that the scale is always in line with the measuring sensor. This helps avoid the Abbé offset error—that is, inaccuracy resulting from minute angles in the machine components. The farther the part to be measured is from the glass-ceramic scale on the machine’s axis, the greater the uncertainty of measurement.

The CMM’s contact and optical sensors feature X-, Y- and Z-axis measuring ranges of 130 by 130 by 100 mm when used separately and 88 by 88 by 74 mm when used together. Able to accommodate workpieces as heavy as 5 kilograms, the CMM comes with the company’s Calypso software for evaluation of measuring data.

Related Content

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreThe Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More