When Cold Forming Threads Makes Sense

Recent tap geometry refinement and advances in coating technologies have made the chip-less, cold-forming operation suitable for a wider range of workpiece materials.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Shops have been cold forming internal threads for quite some time. However, recent tap geometry refinement and advances in coating technologies have made this chipless operation suitable for a wider range of workpiece materials. For example, Emuge (West Boylston, Massachusetts) has developed its Innoform line of cold-forming taps, which is available in 30 geometry and coating combinations for use with seven material groups. This cold-forming tap program is said to be the first to target such an array of individual material groups. Alan Shepherd, Emuge’s technical director who provided the background for this article, explains how cold-forming taps create internal thread profiles and suggests applications for which thread forming is particularly well-suited.

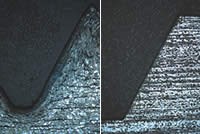

Unlike thread-cutting operations that use fluted taps, cold-forming taps do not make chips. Instead, they displace material to form the shape of the thread. The taps have a polygonal cross section with forming wedges that mirror the thread profile. Their lead taper produces the thread profile, gradually flowing material from the thread crests, along the thread flanks and into the minor diameter area. This material displacement creates the signature claw-shaped seam on the thread crest. (See animation demonstrating this thread-forming action in the Learn More box above.) Because the material is compressed and its grain is redirected, rather than cut or interrupted, strength at the thread flanks and root is increased.

Tapping via cold forming is appropriate for materials with tensile strength less than 1,200 N/mm2 and fracture strain of 5 percent. As a rule of thumb, if a continuous chip is created when drilling, then the material is likely a good candidate for cold forming the threads. However, suitable materials react to cold forming in different ways. That’s why the Innoform tap line has specific combinations of geometry and coatings to thread standard steels; soft steels; hardened steels; stainless steels; cast aluminum; wrought aluminum alloys and non-ferrous metals; and materials with limited ductility. Coatings include titanium nitride, titanium carbonitride and diamond-like amorphous carbon. Anti-friction coatings may also be used for materials such as wrought aluminum to prevent material from adhering to the tap.

Because a high amount of friction is generated during the forming process, use of oil or emulsion coolants is recommended. Minimum quantity lubrication (MQL) can also be used for certain applications. Some Innoform versions have through-tool coolant delivery to assist in threading blind holes. Others exit the through-tool coolant into longitudinal oil grooves to boost tapping speed and thread quality.

The forming taps are available in metric course-thread DIN 13 (M3 to M16) and fine-thread DIN 13 (MF8 × 1 to 16 × 1.5) sizes. The company also offers inch sizes in UNC and UNF. Regardless of the thread size, hole diameter accuracy is vital for proper thread forming. If the hole diameter is too small, workpiece material over-forms in the thread root, and the process forces will be excessive. If the hole is too large, the thread root will not form completely, and the minor diameter will be too small. Tests with custom drill diameters may have to be performed to determine the optimal drill size.

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)